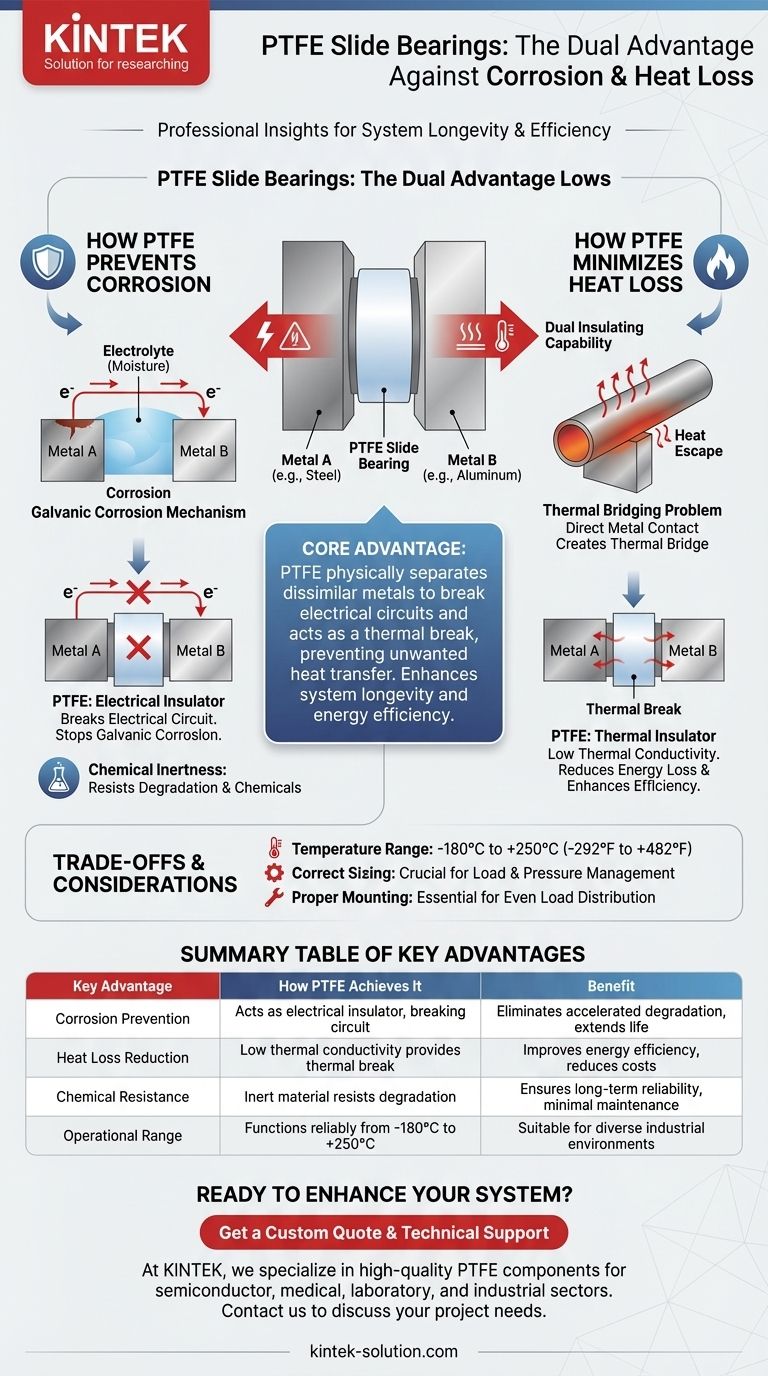

To put it simply, PTFE slide bearings prevent corrosion and heat loss because the material is an excellent electrical and thermal insulator. Unlike traditional metal components like rollers, PTFE creates a non-conductive barrier that stops the electrochemical reactions that cause galvanic corrosion and simultaneously blocks the path for thermal energy to escape the system.

The core advantage of PTFE in this context is its dual insulating capability. It physically separates dissimilar metals to break the electrical circuit that drives corrosion while also acting as a thermal break to prevent unwanted heat transfer, enhancing both system longevity and energy efficiency.

How PTFE Prevents System Corrosion

The longevity of any mechanical or structural system often depends on mitigating corrosion. PTFE slide bearings address this challenge at a fundamental level through their material properties.

The Mechanism of Galvanic Corrosion

Galvanic corrosion is an electrochemical process that occurs when two different metals are in electrical contact in the presence of an electrolyte, like moisture. This creates a small electrical circuit, causing one of the metals to corrode at an accelerated rate.

The Role of Electrical Insulation

PTFE is an exceptional electrical insulator. By placing a PTFE slide bearing between two dissimilar metal components (such as a steel pipe and an aluminum support), you effectively break the electrical circuit. This separation prevents the flow of electrons between the metals, completely stopping the galvanic corrosion process.

The Benefit of Chemical Inertness

Beyond preventing corrosion in other components, PTFE itself is almost entirely chemically inert. It resists degradation from chemicals, moisture, and atmospheric conditions, giving it a nearly indefinite operational life with no risk of the bearing itself becoming a point of failure due to corrosion.

Minimizing Heat Loss and Enhancing Efficiency

In systems that transport heated or cooled substances, such as industrial piping or HVAC systems, energy efficiency is paramount. Unwanted heat transfer represents a direct financial and operational loss.

The Problem of Thermal Bridging

When a metal pipe rests directly on a metal support, the high thermal conductivity of the metals creates a thermal bridge. This bridge provides an easy pathway for heat to escape from the pipe into the support structure and then dissipate into the surrounding environment.

PTFE as a Thermal Insulator

PTFE has very low thermal conductivity, meaning it is a poor conductor of heat. Placing a PTFE slide bearing at the support point introduces a thermal break in the system. This insulating layer significantly reduces the amount of heat energy that can escape, keeping the thermal energy within the pipe where it belongs.

The Impact on System Performance

By minimizing this heat loss, PTFE bearings help maintain the operational temperature of the fluid inside the pipe. This leads to greater energy efficiency, reduced operational costs, and more stable and predictable system performance.

Understanding the Trade-offs and Considerations

While highly effective, PTFE slide bearings are not a universal solution. Proper engineering and an understanding of their operational limits are critical for success.

Temperature Limitations

PTFE has a defined and excellent operational temperature range, but it is not infinite. It performs reliably in continuous service from -180°C up to +250°C (-292°F to +482°F). Applications outside this range require different materials.

The Importance of Correct Sizing

The effectiveness of the bearing is dependent on proper design. Key factors like the load, bearing area, and the number and position of the bearings must be calculated correctly to ensure the pressure on the PTFE material remains within its design limits.

Proper Mounting and Installation

The method used to mount the bearing is also a critical design consideration. An improperly installed bearing can lead to uneven load distribution and premature failure, negating the material's inherent benefits.

Making the Right Choice for Your Application

Selecting the right bearing involves matching its advantages to your primary project goals.

- If your primary focus is preventing corrosion between dissimilar metals: PTFE's electrical insulating properties make it an ideal choice to create a permanent, maintenance-free barrier.

- If your primary focus is maximizing thermal efficiency: PTFE's low thermal conductivity provides a simple and highly effective thermal break at support points, directly reducing energy loss.

- If your primary focus is low-maintenance, long-term reliability: The combination of self-lubrication, chemical inertness, and durability makes PTFE a superior choice for "fit-and-forget" applications.

Ultimately, specifying PTFE slide bearings is an investment in your system's long-term health, efficiency, and reliability.

Summary Table:

| Key Advantage | How PTFE Achieves It | Benefit |

|---|---|---|

| Corrosion Prevention | Acts as an electrical insulator, breaking the circuit between dissimilar metals to stop galvanic corrosion. | Eliminates accelerated metal degradation, extends system life. |

| Heat Loss Reduction | Provides a thermal break due to low thermal conductivity, blocking heat transfer pathways. | Improves energy efficiency, reduces operational costs. |

| Chemical Resistance | Inert material resists degradation from chemicals, moisture, and atmospheric conditions. | Ensures long-term reliability with minimal maintenance. |

| Operational Range | Functions reliably from -180°C to +250°C. | Suitable for a wide variety of industrial and laboratory environments. |

Ready to enhance your system's reliability and efficiency with precision PTFE components?

At KINTEK, we specialize in manufacturing high-quality PTFE slide bearings, seals, liners, and labware tailored for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a perfect fit for your specific application, delivering unmatched corrosion resistance and thermal insulation.

Contact us today to discuss your project needs and discover how our PTFE solutions can protect your investment and optimize performance.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs