At their core, PTFE coated fasteners provide exceptional resistance to corrosion and chemical attack in aggressive plant environments. This chemical inertness prevents the fastener from degrading when exposed to harsh substances, extending its service life, ensuring system integrity, and significantly reducing the risk of failure in critical applications.

The true advantage of PTFE coated fasteners is not merely the protection of the fastener itself, but the enhanced safety, operational reliability, and long-term cost-effectiveness they bring to the entire chemical processing system.

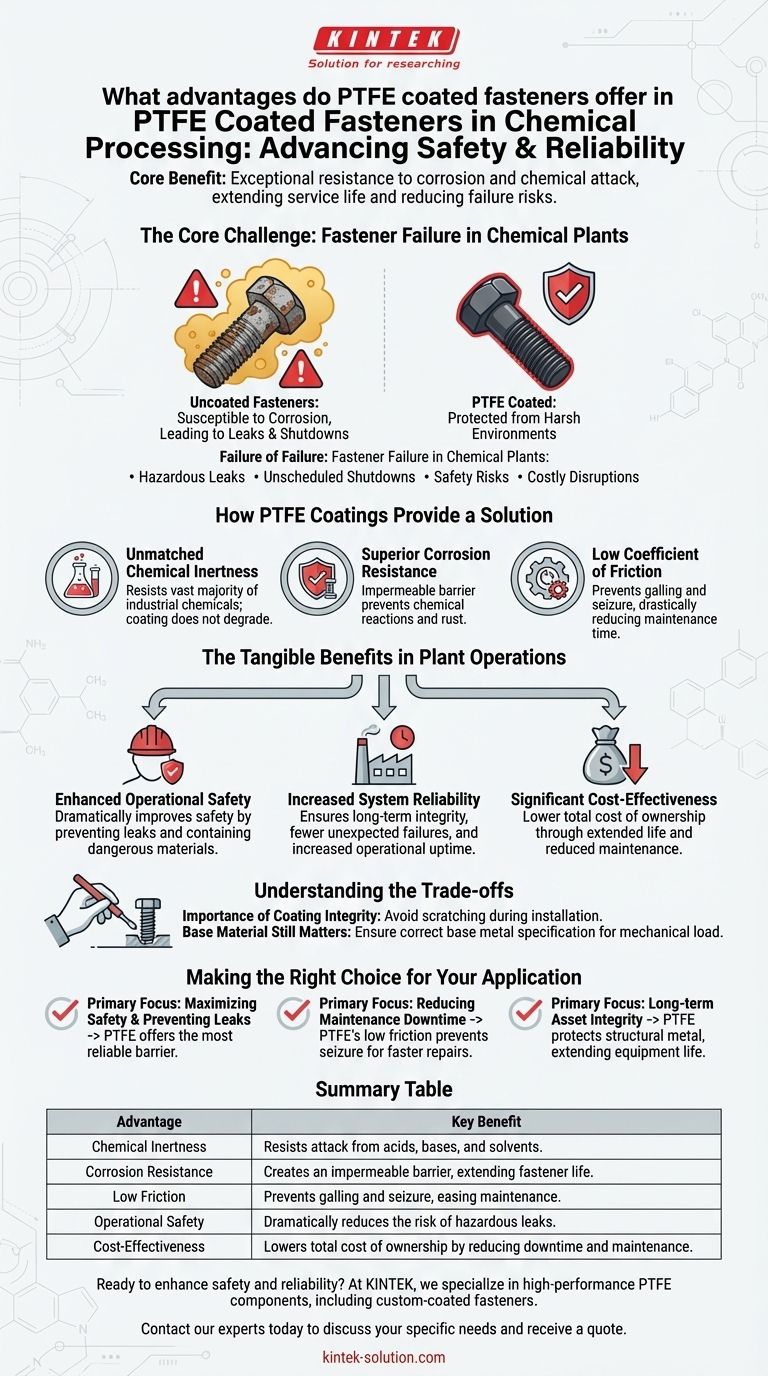

The Core Challenge: Fastener Failure in Chemical Plants

In any chemical processing facility, fasteners are a critical point of potential failure. The environment is uniquely hostile to standard materials.

The Problem with Uncoated Fasteners

Standard steel or alloy fasteners are highly susceptible to corrosion when exposed to the aggressive acids, bases, and solvents common in chemical processing. This chemical attack degrades the material, compromising its structural integrity.

The Impact of Failure

A single corroded fastener can lead to catastrophic outcomes. This includes hazardous leaks, unscheduled shutdowns for emergency maintenance, and significant risks to worker safety, all of which result in costly operational disruptions.

How PTFE Coatings Provide a Solution

A Polytetrafluoroethylene (PTFE) coating acts as a protective shield for the fastener's core metal, delivering several key properties that directly counter the harsh plant environment.

Unmatched Chemical Inertness

PTFE is one of the most chemically inert materials known. It does not react with the vast majority of industrial chemicals, ensuring the coating itself does not break down. This makes it ideal for components in direct contact with aggressive substances.

Superior Corrosion Resistance

The PTFE coating creates an impermeable barrier between the corrosive environment and the load-bearing metal of the fastener. This prevents the chemical reactions that cause rust and degradation, ensuring durability and longevity.

Low Coefficient of Friction

A significant operational benefit of PTFE is its extremely low friction surface. This property prevents galling and seizure during installation and removal, which drastically reduces maintenance time and the labor required for routine inspections or equipment change-outs.

The Tangible Benefits in Plant Operations

Adopting PTFE coated fasteners translates directly into measurable improvements in safety, efficiency, and cost.

Enhanced Operational Safety

By preventing corrosion-induced leaks, PTFE coated fasteners dramatically improve plant safety. As seen in analogous applications where PTFE components reduced hazardous spills by 90%, reliable fastening is crucial for containing dangerous materials and protecting personnel.

Increased System Reliability

Fasteners that resist degradation ensure the long-term integrity of pipes, valves, and processing vessels. This reliability means fewer unexpected failures, leading to more predictable maintenance schedules and increased operational uptime.

Significant Cost-Effectiveness

While the initial purchase price may be higher than for uncoated fasteners, the total cost of ownership is significantly lower. This is achieved through extended fastener life, reduced maintenance labor, minimized downtime, and the prevention of costly cleanups from leaks.

Understanding the Trade-offs

While highly effective, it's important to approach PTFE coated fasteners with a clear understanding of their practical limitations.

The Importance of Coating Integrity

The protection is only as good as the coating itself. Care must be taken during installation to avoid scratching or chipping the PTFE layer, as any damage can create a pathway for corrosion to attack the underlying metal.

Base Material Still Matters

The PTFE coating provides chemical protection, but the base fastener provides the mechanical strength. The underlying bolt material must still be correctly specified to handle the temperature, pressure, and load requirements of the application.

Making the Right Choice for Your Application

Selecting the right fastener is a critical engineering decision based on your primary operational goals.

- If your primary focus is maximizing safety and preventing hazardous leaks: PTFE's chemical inertness offers the most reliable barrier, ensuring the integrity of critical joints and seals.

- If your primary focus is reducing maintenance downtime: The low-friction surface of PTFE prevents fastener seizure, making disassembly for repairs or inspections faster and more efficient.

- If your primary focus is long-term asset integrity: A PTFE coating protects the structural metal of the fastener from its environment, ensuring durability and extending the life of your most critical equipment.

Ultimately, selecting PTFE coated fasteners is a strategic investment in the safety, reliability, and financial performance of your chemical processing operations.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Chemical Inertness | Resists attack from acids, bases, and solvents. |

| Corrosion Resistance | Creates an impermeable barrier, extending fastener life. |

| Low Friction | Prevents galling and seizure, easing maintenance. |

| Operational Safety | Dramatically reduces the risk of hazardous leaks. |

| Cost-Effectiveness | Lowers total cost of ownership by reducing downtime and maintenance. |

Ready to enhance the safety and reliability of your chemical processing operations?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom-coated fasteners, seals, and liners. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get the exact solution for the demanding environments of the semiconductor, medical, laboratory, and industrial sectors.

Invest in components that protect your assets and personnel. Contact our experts today to discuss your specific needs and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs