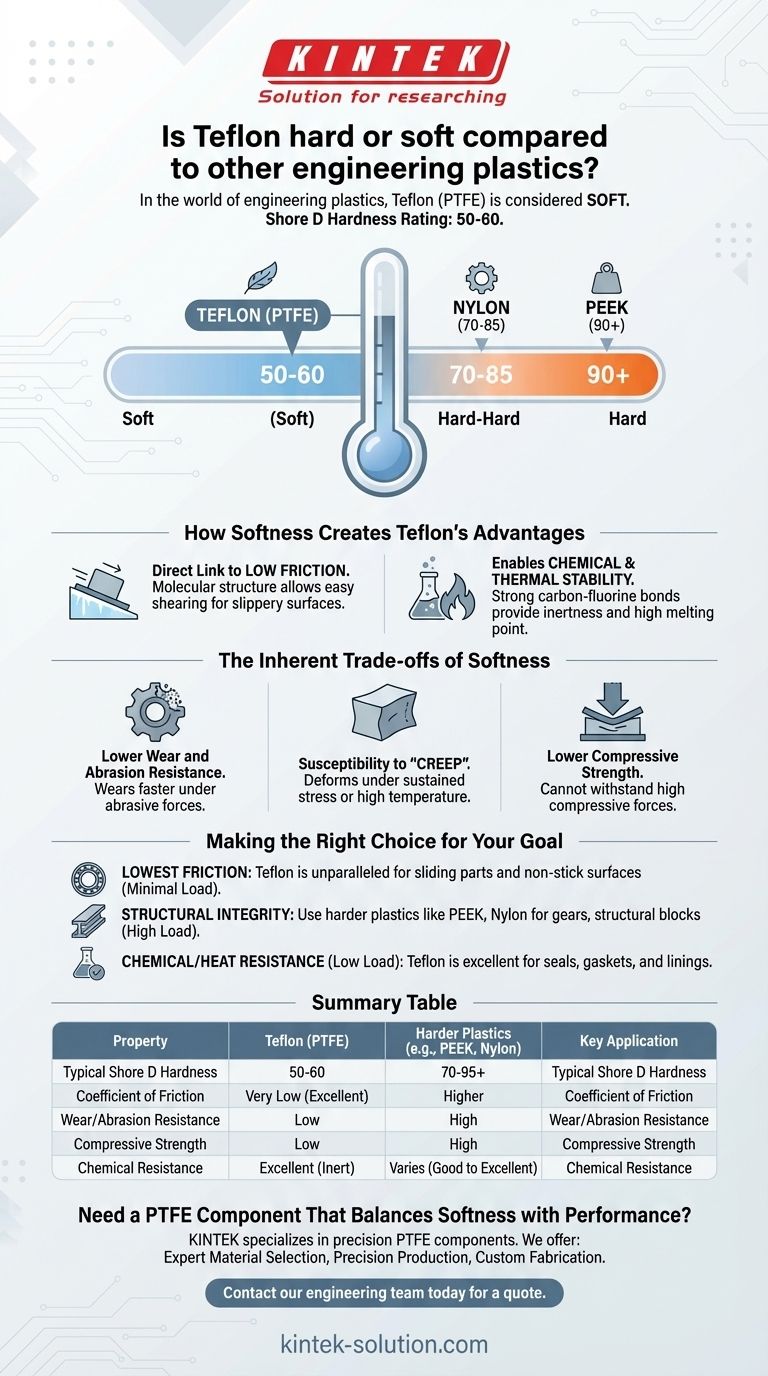

In the world of engineering plastics, Teflon (PTFE) is considered soft. Compared to high-performance polymers like Nylon or PEEK, its typical Shore D hardness rating of 50-60 places it on the lower end of the spectrum. This relative softness is not a flaw; it is directly responsible for the unique properties that make Teflon so valuable.

Teflon's softness is a defining feature, not a bug. It enables its legendary low-friction surface and chemical inertness but comes at the cost of lower wear resistance and compressive strength compared to harder engineering plastics.

What "Hardness" Means for Plastics

Understanding the Shore D Scale

The Shore D scale is a standard method for measuring the hardness of materials, specifically harder plastics and rubbers. It quantifies a material's resistance to permanent indentation from a sharp point under a specific load.

A higher number on the Shore D scale indicates a harder material that is more resistant to scratching and indentation.

Where Teflon Sits on the Spectrum

With a score of 50-60 Shore D, virgin Teflon is significantly softer than many other common engineering plastics.

For comparison, materials like Nylon often score in the 70-85 range, and ultra-high-performance plastics like PEEK can score well into the 90s. This places Teflon in a distinct category of its own.

How Softness Creates Teflon's Advantages

The Direct Link to Low Friction

Teflon's most famous characteristic is its incredibly low coefficient of friction, often compared to wet ice on wet ice. This slipperiness is a direct result of its molecular structure and relative softness.

The material's surface allows for easy shearing, meaning layers can slide past one another with minimal resistance. This makes it an exceptional choice for non-stick coatings and sliding bearings where reducing friction is the primary goal.

Enabling Chemical and Thermal Stability

While many hard plastics can become brittle at high temperatures or degrade when exposed to harsh chemicals, Teflon remains stable.

Its softness is a byproduct of the strong, stable carbon-fluorine bonds that also give it near-universal chemical inertness and a very high melting point. It can handle extreme environments without sacrificing its core properties.

The Inherent Trade-offs of Softness

Lower Wear and Abrasion Resistance

The primary drawback to Teflon's softness is its poor resistance to wear. In applications with significant abrasive forces, it will wear away much faster than a harder plastic like PEEK or Delrin.

This makes it unsuitable for high-load, high-wear components unless it is reinforced with fillers like glass or carbon.

Susceptibility to "Creep"

"Creep" is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress.

Because it is soft, Teflon is susceptible to creep, especially under sustained compressive loads or at elevated temperatures. It can slowly change shape, which is a critical consideration for components requiring tight dimensional tolerances.

Lower Compressive Strength

Teflon cannot withstand the same compressive forces as harder plastics. Applying too much load will cause it to deform or fail.

This limits its use as a primary structural material for parts that must bear significant weight or impact.

Making the Right Choice for Your Goal

- If your primary focus is the lowest possible friction: Teflon is an unparalleled choice for sliding parts, bearings, and non-stick surfaces where the load is minimal.

- If your primary focus is structural integrity and wear resistance: You must consider harder, more rigid plastics like PEEK, Nylon, or Delrin for gears, structural blocks, and high-load bearings.

- If your primary focus is chemical and heat resistance in a low-load environment: Teflon is an excellent material for seals, gaskets, and linings in chemically aggressive or high-temperature settings.

Choosing the right material requires understanding that Teflon's softness and its strengths are two sides of the same coin.

Summary Table:

| Property | Teflon (PTFE) | Harder Plastics (e.g., PEEK, Nylon) |

|---|---|---|

| Typical Shore D Hardness | 50-60 | 70-95+ |

| Coefficient of Friction | Very Low (Excellent) | Higher |

| Wear/Abrasion Resistance | Low | High |

| Compressive Strength | Low | High |

| Chemical Resistance | Excellent (Inert) | Varies (Good to Excellent) |

| Key Application | Non-stick, Low-friction bearings, Seals | High-load structural parts, Gears |

Need a PTFE Component That Balances Softness with Performance?

Teflon's unique properties make it ideal for specific applications, but getting the right formulation and design is critical. KINTEK specializes in manufacturing precision PTFE components—from custom seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors.

We offer:

- Expert Material Selection: Guidance on whether virgin PTFE or a filled compound (e.g., glass-filled for improved wear resistance) is best for your application.

- Precision Production: From prototypes to high-volume orders, we ensure your components meet exact specifications.

- Custom Fabrication: Solve your unique challenges with parts designed for optimal performance in demanding environments.

Let's discuss your project requirements. Contact our engineering team today for a quote or consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications