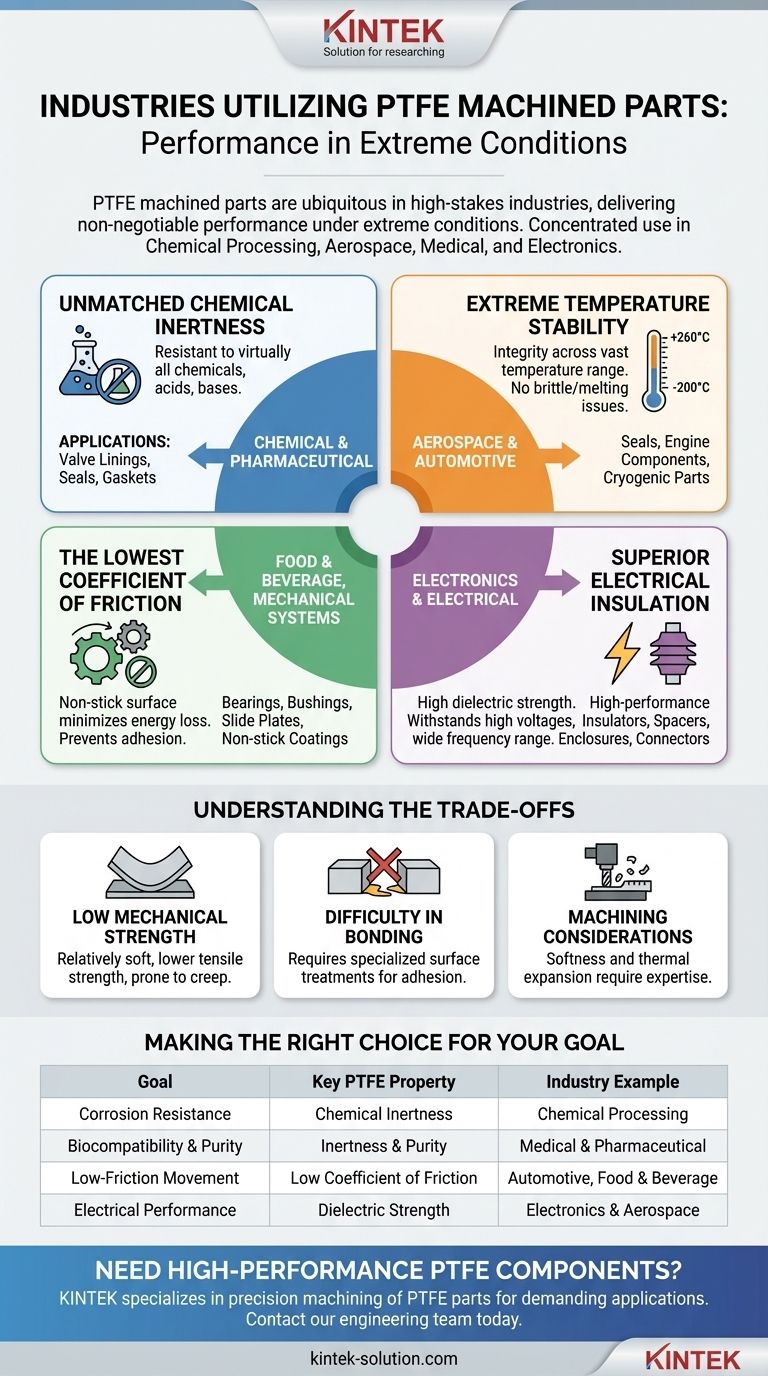

PTFE machined parts are ubiquitous in nearly every high-stakes industry where performance under extreme conditions is non-negotiable. Their use is most concentrated in sectors like chemical processing, aerospace, medical, and electronics. This widespread adoption is driven by PTFE's unique combination of properties, primarily its near-total chemical inertness, high-temperature stability, and exceptionally low coefficient of friction.

The decision to use PTFE is not about a single feature, but about its unparalleled ability to maintain performance and purity in environments where other materials would quickly corrode, degrade, or fail. It is the material of choice for solving problems of extreme chemical exposure, high temperatures, and the need for low-friction, non-contaminating surfaces.

The Core Properties Driving PTFE Adoption

To understand where PTFE is used, one must first understand why it is chosen. Four fundamental properties make it an indispensable engineering material.

Unmatched Chemical Inertness

PTFE is resistant to virtually all industrial chemicals, acids, and bases. This makes it an ideal material for any application involving the handling of corrosive fluids.

This property is critical in the chemical, petrochemical, and pharmaceutical industries. Components like valve linings, seals, and gaskets made from PTFE ensure that equipment is not degraded by the substances it contains, preventing costly failures and contamination.

Extreme Temperature Stability

PTFE maintains its integrity across a vast temperature range, typically from -200°C to +260°C (-328°F to +500°F). It does not become brittle in cryogenic conditions nor does it melt at high operating temperatures.

This stability is essential for aerospace and automotive applications. It is used for seals and components that must perform reliably in the extreme cold of space or within the high-temperature environment of an engine compartment.

The Lowest Coefficient of Friction

Known for its non-stick, "slippery" surface, PTFE has one of the lowest coefficients of friction of any solid material. This minimizes energy loss in moving parts and prevents other materials from adhering to its surface.

This is leveraged in mechanical systems for bearings, bushings, and slide plates where smooth, low-effort movement is required. It is also the reason PTFE is used for non-stick coatings in the food and beverage industry, ensuring efficient and clean processing.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength, meaning it can withstand high voltages without breaking down. It also maintains these properties across a wide range of frequencies.

This makes it a cornerstone material in the electronics and electrical industries. It is machined into high-performance insulators, spacers, and enclosures for sensitive connectors and components, especially in high-frequency applications like radar and satellite communications.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Low Mechanical Strength

Compared to other engineering plastics like PEEK or nylon, PTFE is a relatively soft material. It has lower tensile strength and wear resistance, making it less suitable for high-load structural applications.

Under sustained pressure, PTFE can be subject to "creep" or cold flow, where the material slowly deforms over time. This must be accounted for in component design, especially for seals and gaskets.

Difficulty in Bonding

The same non-stick properties that make PTFE so useful also make it extremely difficult to bond to other materials using conventional adhesives.

Joining PTFE to other substrates requires specialized surface treatments, such as chemical etching, which adds complexity and cost to the manufacturing process.

Machining Considerations

While PTFE is readily machinable, its softness and thermal expansion characteristics require specific expertise. Using incorrect tools or speeds can result in poor surface finishes, thermal stress, or difficulty holding tight tolerances.

Making the Right Choice for Your Goal

Selecting PTFE is a strategic decision based on the primary challenge you need to solve. Consider the following scenarios to determine if it aligns with your objective.

- If your primary focus is corrosion resistance: PTFE is the industry standard for handling aggressive chemicals, making it ideal for linings, seals, and gaskets in chemical plants.

- If your primary focus is biocompatibility and purity: Its inertness makes it a first choice for medical implants, surgical instruments, and components in food and pharmaceutical processing equipment.

- If your primary focus is low-friction movement: PTFE's exceptionally low coefficient of friction is perfect for high-performance bearings, slide plates, and non-stick surfaces.

- If your primary focus is electrical performance: Its high dielectric strength makes it an essential material for insulators in demanding electronics and aerospace applications.

Ultimately, choosing PTFE is a decision to engineer for reliability and longevity in the most demanding operational environments.

Summary Table:

| Industry | Primary Use of PTFE Parts | Key PTFE Property Utilized |

|---|---|---|

| Chemical Processing | Seals, gaskets, valve liners | Unmatched chemical inertness |

| Medical & Pharmaceutical | Surgical tools, implants, labware | Biocompatibility and purity |

| Aerospace & Automotive | Seals, insulators, bushings | Extreme temperature stability |

| Electronics & Electrical | High-frequency insulators, spacers | Superior dielectric strength |

| Food & Beverage | Non-stick coatings, bearings | Low coefficient of friction |

Need high-performance PTFE components for your demanding application?

At KINTEK, we specialize in precision machining of PTFE parts—from custom prototypes to high-volume production. Our expertise ensures your components meet the strictest requirements for chemical resistance, thermal stability, and purity in industries like semiconductor, medical, and industrial manufacturing.

Contact our engineering team today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability