In short, PTFE gaskets are used in nearly every industry where harsh conditions are the norm. They are a cornerstone sealing solution in sectors like chemical processing, pharmaceuticals, food and beverage, and aerospace due to a unique combination of chemical inertness, temperature resistance, and non-contaminating properties.

The widespread use of PTFE gaskets is not about the industries themselves, but about the demanding operational challenges within them. PTFE is the material of choice when a seal must withstand aggressive chemicals, extreme temperatures, or maintain absolute product purity.

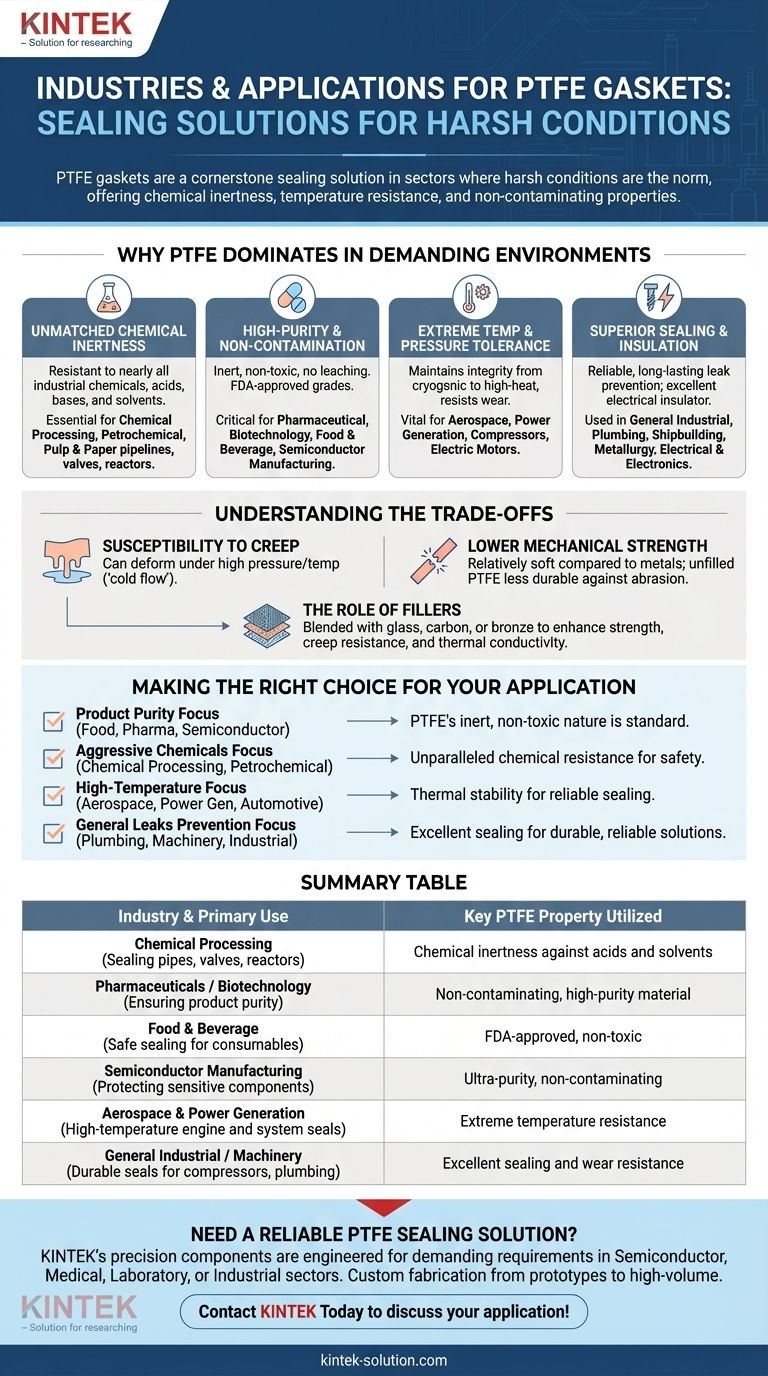

Why PTFE Dominates in Demanding Environments

Polytetrafluoroethylene (PTFE) is not just a single-use material; its versatility makes it a problem-solver across a wide spectrum of applications. Its value is rooted in a few key properties that are critical in high-stakes industrial processes.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, including strong acids, bases, and corrosive solvents. This makes it an essential component for ensuring safety and process integrity.

This property is critical in the chemical processing, petrochemical, and pulp and paper industries, where gaskets are constantly exposed to aggressive media in pipelines, valves, and reactors.

High-Purity and Non-Contamination

Because PTFE is an inert and non-toxic material, it does not leach chemicals or contaminate the substances it contacts. Many grades are FDA-approved for direct food contact.

This is non-negotiable for the pharmaceutical, biotechnology, and food and beverage industries, where product purity is paramount. It's also vital in semiconductor manufacturing, where even microscopic contamination can ruin sensitive electronic components.

Extreme Temperature and Pressure Tolerance

PTFE gaskets maintain their sealing integrity across a broad temperature range, from cryogenic levels to high-heat applications. They also offer excellent wear resistance in dynamic applications.

This resilience is crucial for the aerospace industry (in engines and components), power generation (for stable, durable seals), and in demanding machinery like compressors and electric motors that operate under extreme conditions.

Superior Sealing and Insulation

PTFE's physical properties create a reliable, long-lasting seal that prevents leaks of liquids or gases. It is also an excellent electrical insulator.

This makes it a go-to choice for general industrial applications in plumbing, shipbuilding, and metallurgy. Its insulating properties are highly valued in the electrical and electronics industries for sealing wiring systems and preventing leaks in sensitive equipment.

Understanding the Trade-offs

While incredibly versatile, standard PTFE is not a universal solution. Understanding its limitations is key to using it effectively.

Susceptibility to Creep

Under high pressure, especially at elevated temperatures, standard PTFE can be subject to "creep" or "cold flow," where the material slowly deforms over time. This can lead to a loss of bolt torque and potential leaks.

Lower Mechanical Strength

Compared to metals, PTFE is a relatively soft material. In applications with high surface abrasion or where extreme rigidity is needed, unfilled PTFE might not be the optimal choice.

The Role of Fillers

To overcome these limitations, PTFE is often blended with fillers like glass, carbon, or bronze. This creates "filled PTFE" gaskets that offer enhanced strength, improved creep resistance, and better thermal conductivity, expanding their use in even more demanding applications.

Making the Right Choice for Your Application

Selecting the right gasket depends entirely on the primary challenge you need to solve.

- If your primary focus is product purity: PTFE's inert, non-toxic nature makes it the standard for food, pharmaceutical, and semiconductor applications.

- If your primary focus is handling aggressive chemicals: PTFE's unparalleled chemical resistance is essential for safety in the chemical processing and petrochemical industries.

- If your primary focus is high-temperature performance: Its thermal stability is critical for reliable sealing in aerospace, power generation, and automotive engines.

- If your primary focus is preventing leaks under standard conditions: PTFE's excellent sealing properties provide a durable and reliable solution for general plumbing, machinery, and industrial use.

Ultimately, understanding PTFE's core properties is the key to leveraging its power in any critical sealing application.

Summary Table:

| Industry | Primary Use of PTFE Gaskets | Key PTFE Property Utilized |

|---|---|---|

| Chemical Processing | Sealing pipes, valves, reactors | Chemical inertness against acids and solvents |

| Pharmaceuticals / Biotechnology | Ensuring product purity | Non-contaminating, high-purity material |

| Food & Beverage | Safe sealing for consumables | FDA-approved, non-toxic |

| Semiconductor Manufacturing | Protecting sensitive components | Ultra-purity, non-contaminating |

| Aerospace & Power Generation | High-temperature engine and system seals | Extreme temperature resistance |

| General Industrial / Machinery | Durable seals for compressors, plumbing | Excellent sealing and wear resistance |

Need a Reliable PTFE Sealing Solution?

Whether you're in the semiconductor, medical, laboratory, or industrial sector, KINTEK's precision PTFE components are engineered to meet your most demanding requirements. We specialize in custom fabrication—from prototypes to high-volume orders—ensuring your gaskets, seals, and liners deliver unmatched performance in harsh conditions.

Contact KINTEK today to discuss your specific application and receive a expert solution tailored for durability, purity, and chemical resistance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications