PTFE bushes are most advantageous in applications where conventional lubricants are impractical or forbidden, and where components are exposed to corrosive chemicals, extreme temperatures, or require minimal maintenance. They excel in high-performance equipment and precision machinery across industries like chemical processing, food manufacturing, and medical technology, where traditional metal or plastic bushings would quickly fail.

The decision to use a PTFE bush is less about a specific type of machine and more about the hostile operating environment it must endure. Its unique combination of self-lubrication, chemical inertness, and temperature stability solves critical engineering problems that traditional lubricated metal bearings simply cannot.

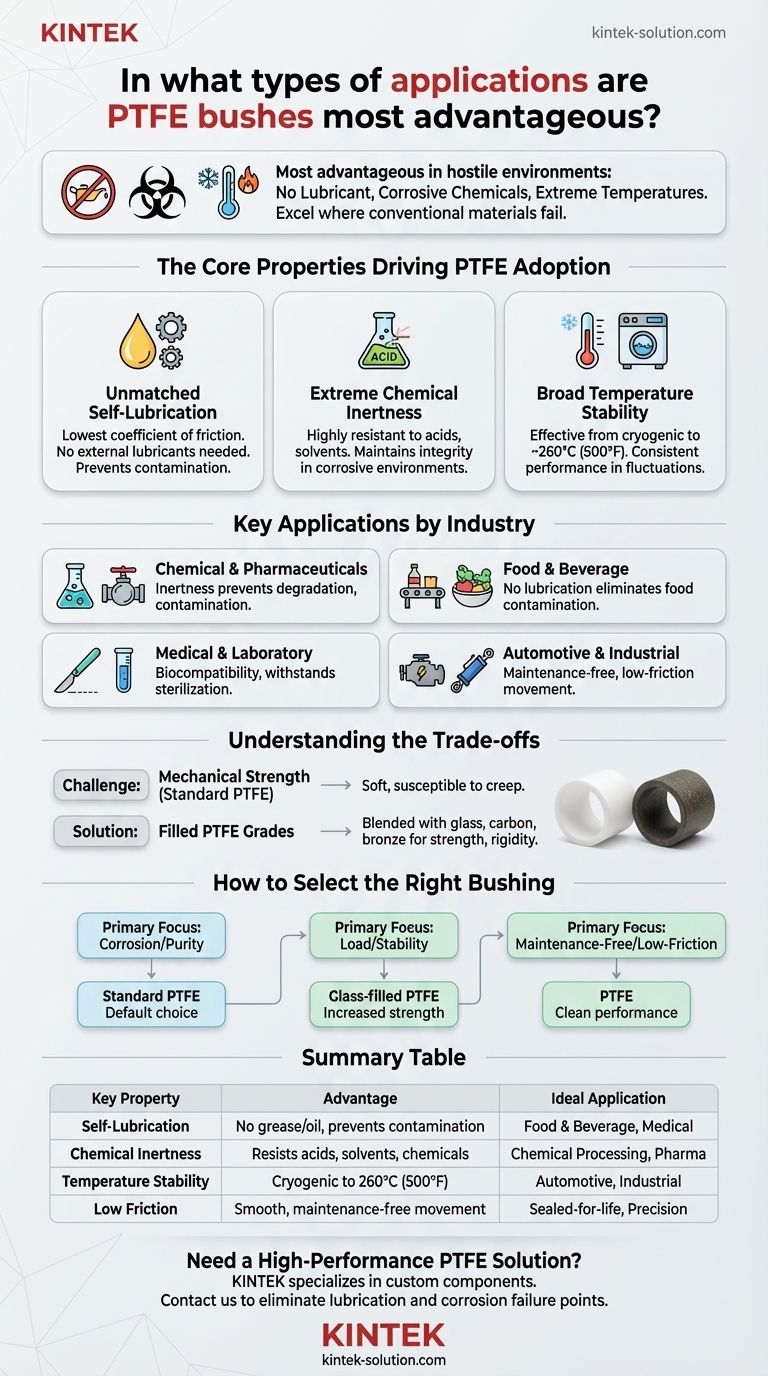

The Core Properties Driving PTFE Adoption

To understand where PTFE bushes are most effective, we must first analyze the fundamental properties that set them apart. These characteristics directly address the common failure points of other bearing materials.

Unmatched Self-Lubrication

PTFE has one of the lowest coefficients of friction of any solid material. This allows it to function as a self-lubricating bearing surface.

This is critical in applications where external lubricants like grease or oil are undesirable due to potential contamination (food processing), incompatibility with processes (medical devices), or difficulty in reapplication (sealed-for-life components).

Extreme Chemical Inertness

PTFE is highly resistant to nearly all industrial chemicals, acids, and solvents. It maintains its structural integrity and performance in environments that would rapidly corrode and destroy even specialized metal bearings.

This makes PTFE the default choice for equipment used in chemical processing, oil and gas, and pharmaceutical manufacturing, such as pumps, valves, and mixers.

Broad Temperature Stability

PTFE bushes can operate effectively across a wide temperature range, from cryogenic levels up to approximately 260°C (500°F).

This stability ensures consistent, low-friction performance in machinery that experiences significant temperature fluctuations, from automotive engine components to industrial ovens.

Key Applications by Industry

These core properties make PTFE bushes the ideal solution for specific challenges across several key sectors.

Chemical Processing & Pharmaceuticals

In pumps, mixers, and valves handling aggressive chemicals, PTFE's inertness prevents degradation of the bushing and contamination of the product. Its self-lubricating nature is essential for maintaining purity.

Food & Beverage Manufacturing

PTFE is a preferred material for conveyor systems, mixers, and packaging equipment. Because it requires no external lubrication, it eliminates the risk of contaminating food products with grease or oil.

Medical & Laboratory Devices

The combination of chemical resistance and biocompatibility makes PTFE suitable for surgical instruments and laboratory equipment. These devices must withstand harsh sterilization processes and operate without lubricants.

Automotive & Industrial Machinery

In components like suspension struts, steering columns, and hydraulic cylinders, PTFE-lined bearings provide maintenance-free, low-friction movement. They are lightweight and resist degradation from automotive fluids and industrial solvents.

Understanding the Trade-offs

While its advantages are significant, it is crucial to understand the limitations of PTFE to ensure proper application.

The Challenge of Mechanical Strength

Standard, unfilled PTFE is a relatively soft material. It has lower compressive strength and is more susceptible to creep (slow deformation under load) than metal bearings.

This makes it unsuitable for very high-load, high-precision applications where dimensional stability is the absolute top priority.

The Solution: Filled PTFE Grades

To overcome the mechanical limitations, PTFE can be blended with reinforcing fillers like glass, carbon, or bronze.

Glass-filled PTFE, for example, offers significantly increased mechanical strength, rigidity, and creep resistance. This enhancement expands its use into more demanding industrial applications without sacrificing its excellent chemical resistance and low friction.

Interaction with Shaft Materials

Because PTFE is a soft material, it is an excellent choice for use with softer shaft materials. Unlike a hard metal bearing, a PTFE bush is less likely to cause wear or damage to the shaft itself.

How to Select the Right Bushing for Your Goal

Your final decision should be based on the primary challenge you need to solve.

- If your primary focus is corrosion resistance and purity: Standard PTFE is the default choice due to its unmatched chemical inertness and self-lubricating nature.

- If your primary focus is load-bearing capacity and dimensional stability: Consider a glass-filled PTFE to gain mechanical strength without sacrificing chemical and thermal resistance.

- If your primary focus is maintenance-free, low-friction movement: PTFE provides excellent, clean performance in applications where traditional grease or oil is unacceptable.

Ultimately, choosing PTFE is a strategic engineering decision to eliminate common failure points related to lubrication, corrosion, and contamination.

Summary Table:

| Key Property | Advantage | Ideal Application |

|---|---|---|

| Self-Lubrication | Eliminates need for grease/oil, prevents contamination | Food & Beverage, Medical Devices |

| Chemical Inertness | Resists acids, solvents, and aggressive chemicals | Chemical Processing, Pharmaceuticals |

| Temperature Stability | Performs from cryogenic to 260°C (500°F) | Automotive, Industrial Machinery |

| Low Friction | Provides smooth, maintenance-free movement | Sealed-for-life components, Precision instruments |

Need a High-Performance PTFE Solution for Your Application?

KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, labware, and high-performance bushes—for the semiconductor, medical, laboratory, and industrial sectors.

We understand the critical balance between chemical resistance, self-lubrication, and mechanical strength. Whether you need a standard PTFE bushing for ultimate purity or a glass-filled PTFE version for enhanced load-bearing capacity, our team can fabricate the perfect solution from prototype to high-volume production.

Let us help you eliminate failure points related to lubrication and corrosion.

Contact KINTEK today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance