To put it directly, Polytetrafluoroethylene (PTFE) is the material of choice for applications involving aggressive chemicals across numerous industries. Its near-total chemical inertness makes it indispensable in chemical processing, pharmaceutical manufacturing, oil and gas, and food production for components like gaskets, seals, and linings that must withstand substances like sulfuric acid, solvents, and alkalis without degrading.

The core reason PTFE is so widely trusted is its unparalleled chemical stability. This property ensures operational safety by preventing leaks of hazardous materials and guarantees product purity by eliminating the risk of material contamination in sensitive processes.

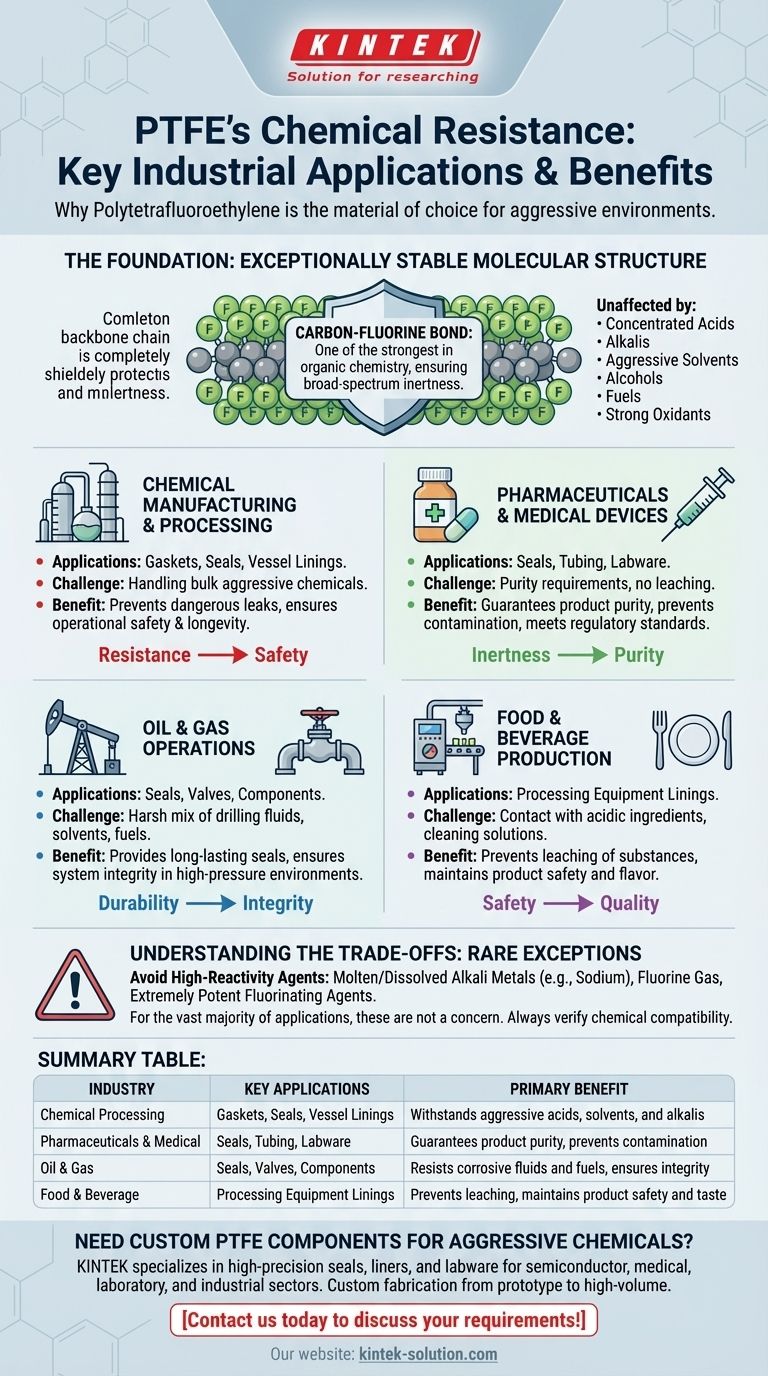

The Foundation: Why PTFE Resists Chemical Attack

An Exceptionally Stable Molecular Structure

PTFE's remarkable chemical resistance stems from its molecular structure, which is composed of a carbon backbone completely shielded by a dense layer of fluorine atoms.

The carbon-fluorine bond is one of the strongest single bonds in organic chemistry. This immense strength makes the molecule exceptionally stable and non-reactive, as it is very difficult for other chemicals to break these bonds and cause a reaction.

Broad-Spectrum Inertness

This molecular stability translates into an inertness to a vast range of chemicals. PTFE remains unaffected by highly corrosive substances, including concentrated acids (sulfuric, hydrochloric), alkalis, aggressive solvents (acetone, chloroform), alcohols, fuels, and strong oxidants.

This allows it to perform reliably where most metals and plastics would quickly fail.

Key Industrial Applications Driven by Resistance

Chemical Manufacturing and Processing

In plants that handle bulk aggressive chemicals, equipment failure is not an option. PTFE is used extensively for gaskets, seals, and vessel linings.

These components create reliable seals that prevent dangerous leaks of hazardous materials. Its ability to withstand both corrosive chemicals and high temperatures makes it essential for ensuring operational safety and longevity.

Pharmaceuticals and Medical Devices

Purity is the primary concern in pharmaceutical and medical applications. PTFE's inertness is critical because it will not react with or leach into sensitive chemical compounds or final products.

This non-reactivity ensures that the manufactured drugs or medical devices remain pure and uncontaminated, which is a fundamental requirement for regulatory approval and patient safety.

Oil and Gas Operations

The oil and gas industry exposes equipment to a harsh mix of corrosive substances, from drilling fluids and solvents to refined fuels.

PTFE components are used to handle these materials, providing long-lasting seals and parts that do not swell, weaken, or degrade upon exposure, ensuring system integrity in high-pressure environments.

Food and Beverage Production

Similar to pharmaceuticals, the food industry demands materials that will not contaminate the product.

PTFE is used in processing equipment where it might come into contact with acidic ingredients, cleaning solutions, or various solvents. Its stability ensures that no unwanted flavors or substances are transferred to the food.

Understanding the Trade-offs: The Few Exceptions

High-Reactivity Agents to Avoid

While its resistance is vast, PTFE is not invincible. It is vulnerable to a very specific and small class of highly reactive substances.

The primary materials that can attack PTFE are molten or dissolved alkali metals (like sodium), fluorine gas, and other extremely potent fluorinating agents.

Why These Exceptions Are Critical

For the overwhelming majority of industrial applications, these exceptions are not a concern.

However, in specialized environments where these specific substances are present, using PTFE would lead to rapid and catastrophic failure. Always verifying chemical compatibility against your specific operational profile is a critical step in material selection.

Making the Right Choice for Your Goal

Selecting the right material is about matching its properties to your primary challenge.

- If your primary focus is handling aggressive acids and solvents: PTFE is the industry benchmark for seals, gaskets, and linings due to its broad, reliable resistance.

- If your primary focus is product purity and non-contamination: PTFE's chemical inertness is non-negotiable, as it guarantees it will not react with or leach into your end product.

- If your primary focus is safety in high-risk environments: Verify that your process does not involve the rare exceptions, like molten alkali metals or fluorine gas, that can degrade PTFE.

Ultimately, leveraging PTFE's near-universal chemical resistance allows you to engineer systems that are safer, more reliable, and longer-lasting.

Summary Table:

| Industry | Key PTFE Applications | Primary Benefit |

|---|---|---|

| Chemical Processing | Gaskets, Seals, Vessel Linings | Withstands aggressive acids, solvents, and alkalis |

| Pharmaceuticals & Medical | Seals, Tubing, Labware | Guarantees product purity, prevents contamination |

| Oil & Gas | Seals, Valves, Components | Resists corrosive fluids and fuels, ensures integrity |

| Food & Beverage | Processing Equipment Linings | Prevents leaching, maintains product safety and taste |

Need a custom PTFE component that can handle your most aggressive chemicals?

At KINTEK, we specialize in manufacturing high-precision PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services, from prototypes to high-volume orders, ensure you get a solution that guarantees safety, purity, and longevity in your operations.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications