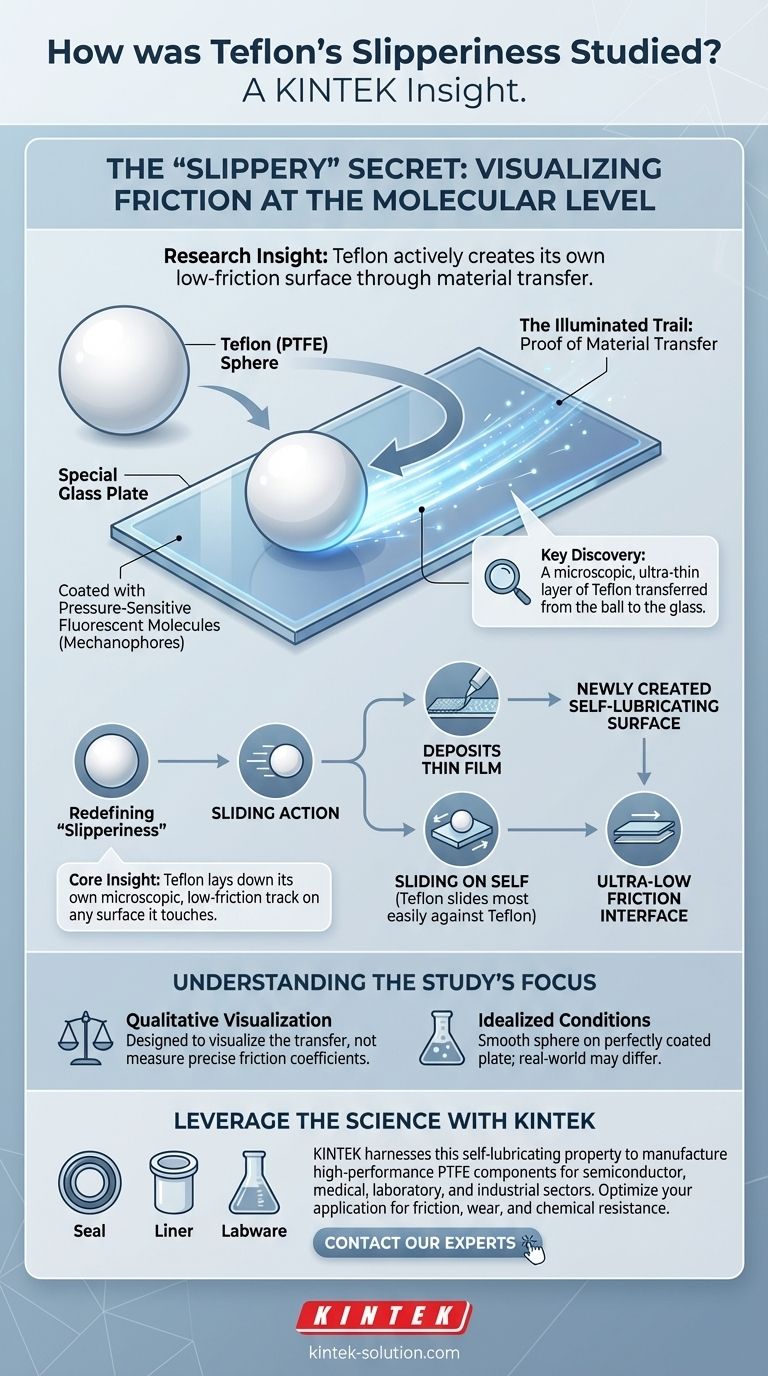

To study the slipperiness of Teflon, researchers dragged a Teflon ball across a glass plate coated with special fluorescent molecules designed to light up under pressure. As the ball moved, it left behind a distinct, illuminated trail. This trail proved that a microscopic, ultra-thin layer of Teflon had transferred from the ball to the glass, creating the low-friction surface.

The core insight from this research is that Teflon's famous slipperiness isn't just an inherent surface property. It is an active process of material transfer, where Teflon lays down its own microscopic, low-friction track on any surface it touches.

Visualizing Friction at the Molecular Level

To understand the "why" behind Teflon's low friction, the researchers needed a way to see what was happening at the contact point. They designed an experiment that made this invisible interaction visible.

The Experimental Setup

The setup consisted of two primary components: a standard Teflon (PTFE) ball and a specialized glass plate. This simple arrangement was designed to isolate the interaction between the two materials.

Pressure-Sensitive Molecules

The key to the experiment was the glass plate's unique coating. It was covered in special fluorescent molecules. These molecules are "mechanophores," meaning they react to mechanical force—in this case, by lighting up when pressure is applied.

The "Illuminated Trail"

When the Teflon ball was dragged across the plate, the pressure at the point of contact activated the fluorescent molecules, causing them to glow. This created a clear, illuminated path marking exactly where the ball had been.

Proving Material Transfer

Crucially, the trail remained lit even after the ball had passed. This indicated that something was still applying pressure to the fluorescent molecules. That "something" was a microscopic layer of Teflon that had sheared off the ball and adhered to the glass plate.

The Deeper Implications of Material Transfer

This experiment fundamentally clarifies how Teflon works. The visualization of the transferred film provides direct evidence for the mechanism responsible for its low-friction properties.

Redefining "Slipperiness"

The study shows that when you slide a Teflon object, it isn't just sliding on its own surface. It is actively depositing a thin film onto the opposing surface and then sliding against that newly created film of itself. Teflon slides most easily against Teflon.

An Ultra-Thin, Self-Lubricating Layer

The transferred material creates an exceptionally smooth, low-friction interface. This self-lubricating action is what gives Teflon its uniquely slippery feel and makes it an invaluable material in applications from non-stick cookware to industrial bearings.

Understanding the Study's Focus

While powerful, this visualization technique has a specific scope. Understanding its limitations is key to interpreting the results correctly.

A Qualitative Visualization

This experiment is primarily qualitative; it was designed to visualize the phenomenon of material transfer, not to measure the precise coefficient of friction. It proves that transfer occurs but doesn't quantify how factors like speed, temperature, or load affect the friction force itself.

Idealized Conditions

The experiment uses a smooth Teflon sphere on a perfectly smooth, coated glass plate. Real-world scenarios often involve rougher surfaces and different contact geometries, which could influence how the Teflon film is deposited and how durable it is.

Key Insights for Your Application

The findings from this research method provide clear, actionable takeaways for anyone working with low-friction materials.

- If your primary focus is understanding the mechanism: The critical insight is that Teflon actively creates its own low-friction surface by transferring a microscopic film.

- If your primary focus is on material science: This study demonstrates a powerful method for visualizing material transfer and wear at the molecular level, opening doors for studying other polymers.

By making an invisible process visible, this research reveals that the secret to Teflon's slipperiness is its ability to lay down its own path.

Summary Table:

| Aspect of the Study | Key Finding |

|---|---|

| Experimental Method | Dragged a Teflon ball on a glass plate coated with pressure-sensitive fluorescent molecules. |

| Visualized Phenomenon | An illuminated trail was left behind, proving material transfer from the ball to the glass. |

| Core Insight | Teflon's slipperiness is an active process of depositing a low-friction film of itself onto other surfaces. |

| Study Focus | Qualitative visualization of the transfer mechanism, not quantitative friction measurement. |

Leverage the Science of Low-Friction Materials with KINTEK

This research highlights a fundamental principle: PTFE (Teflon) excels by creating its own ultra-thin, low-friction interface. At KINTEK, we harness this property to manufacture precision PTFE components—including seals, liners, and custom labware—that deliver superior, long-lasting performance.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise in custom fabrication from prototypes to high-volume orders ensures you get components optimized for your specific friction, wear, and chemical resistance requirements.

Ready to integrate high-performance PTFE solutions into your application? Contact our experts today to discuss how we can help you achieve unparalleled reliability and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F