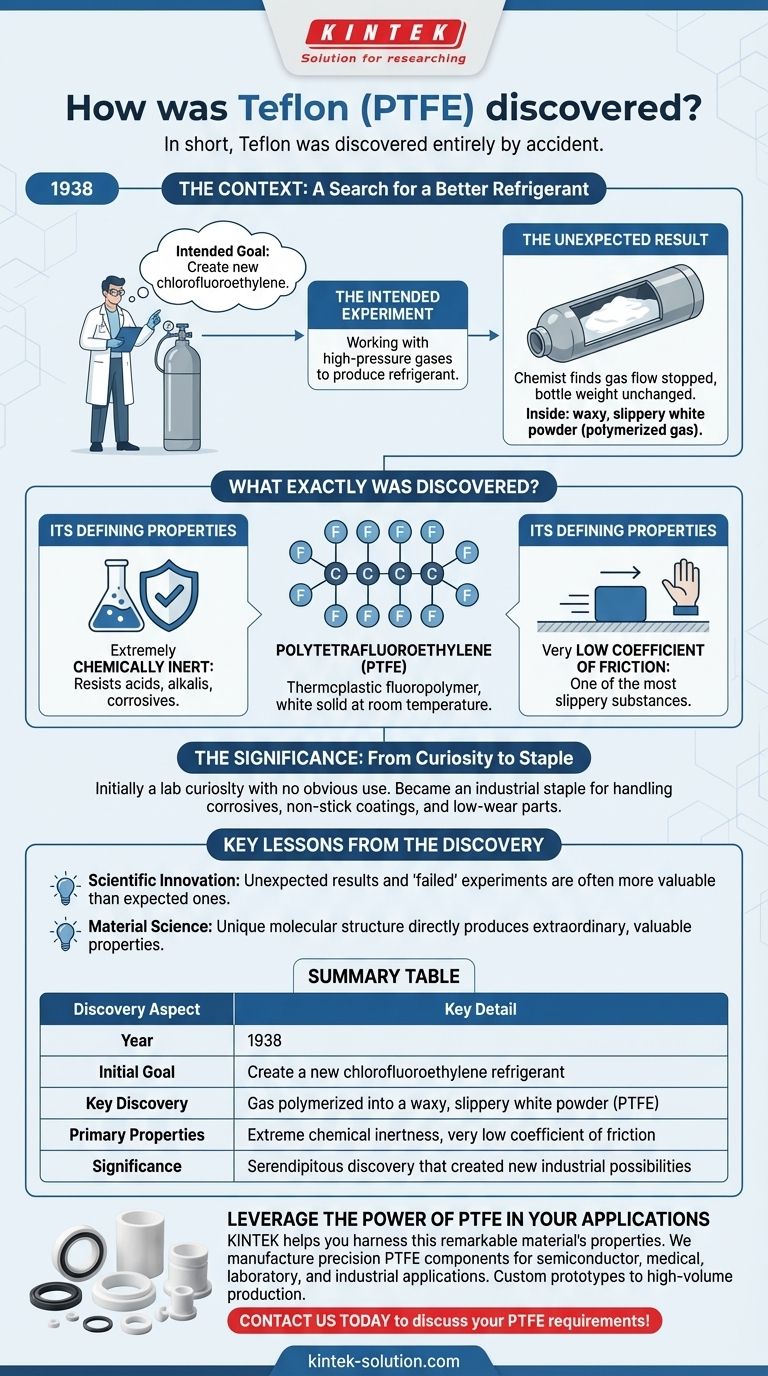

In short, Teflon was discovered entirely by accident. In 1938, a chemist working to create a new refrigerant, chlorofluoroethylene, returned to a pressurized bottle of gas he had been using. He found that while the pressure was gone, the bottle's weight hadn't changed, and inside he discovered a strange, waxy white powder that was remarkably slippery.

The discovery of Polytetrafluoroethylene (PTFE), or Teflon, was not the result of a targeted search for a new polymer. Instead, it was a serendipitous accident that revealed a material with properties so unique they would go on to create entirely new industrial possibilities.

The Context: A Search for a Better Refrigerant

The story of Teflon's discovery is a classic example of scientific curiosity turning a failed experiment into a monumental success. The initial goal had nothing to do with creating a new material.

The Intended Experiment

The experiment's objective was to produce a new type of chlorofluoroethylene, which was intended for use as a refrigerant. This involved working with gases under high pressure in metal cylinders.

The Unexpected Result

Upon inspecting one of the gas cylinders, the chemist found that the gas flow had stopped, yet the cylinder still weighed the same. After cutting the bottle open, he discovered that its interior was coated with a waxy, slippery white material that was unlike anything he had seen before. The gas had polymerized into a solid.

What Exactly Was Discovered?

The substance found inside that bottle was Polytetrafluoroethylene, or PTFE. Its accidental creation revealed a material with a rare and valuable combination of characteristics.

The Chemical Nature of PTFE

PTFE is a thermoplastic fluoropolymer. This specific chemical structure is the source of its famous properties. At room temperature, it exists as a white solid.

Its Defining Properties

The new material was found to be incredibly chemically inert, meaning it did not react with acids, alkalis, or other corrosive chemicals. Crucially, it also possessed an extremely low coefficient of friction, making it one of the most slippery substances known.

The Significance of an Accidental Find

This discovery highlights a critical principle in research and development: the importance of investigating anomalies. What began as a frustrating experimental error became the genesis of a revolutionary material.

A Solution in Search of a Problem

Initially, the new substance was a curiosity. Its extreme properties—particularly its resistance to corrosion and its slipperiness—were impressive, but there was no immediate, obvious application for such an expensive and unusual material.

From Lab Curiosity to Industrial Staple

Over time, engineers realized that these unique properties could solve complex problems. Its chemical inertness made it invaluable for handling corrosive materials, and its low-friction surface created possibilities for non-stick coatings and low-wear industrial parts.

Key Lessons from the Discovery

The story of Teflon offers more than just a historical anecdote; it provides powerful insights into the nature of innovation.

- If your primary focus is on scientific innovation: The key lesson is that unexpected results and "failed" experiments are often more valuable than the expected ones.

- If your primary focus is on material science: This discovery proves how a unique molecular structure can directly produce extraordinary and commercially valuable physical properties.

Ultimately, the creation of Teflon serves as a definitive reminder that progress is often born from curiosity and the willingness to explore the unknown.

Summary Table:

| Discovery Aspect | Key Detail |

|---|---|

| Year | 1938 |

| Initial Goal | Create a new chlorofluoroethylene refrigerant |

| Key Discovery | Gas polymerized into a waxy, slippery white powder (PTFE) |

| Primary Properties | Extreme chemical inertness, very low coefficient of friction |

| Significance | Serendipitous discovery that created new industrial possibilities |

Leverage the Power of PTFE in Your Applications

Just as the accidental discovery of PTFE opened new industrial frontiers, KINTEK can help you harness this remarkable material's properties for your specialized needs. We manufacture precision PTFE components—including seals, liners, and labware—for semiconductor, medical, laboratory, and industrial applications. Whether you need custom prototypes or high-volume production, our expertise ensures superior performance and durability.

Contact us today to discuss your PTFE requirements and discover how our solutions can solve your most challenging material problems!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance