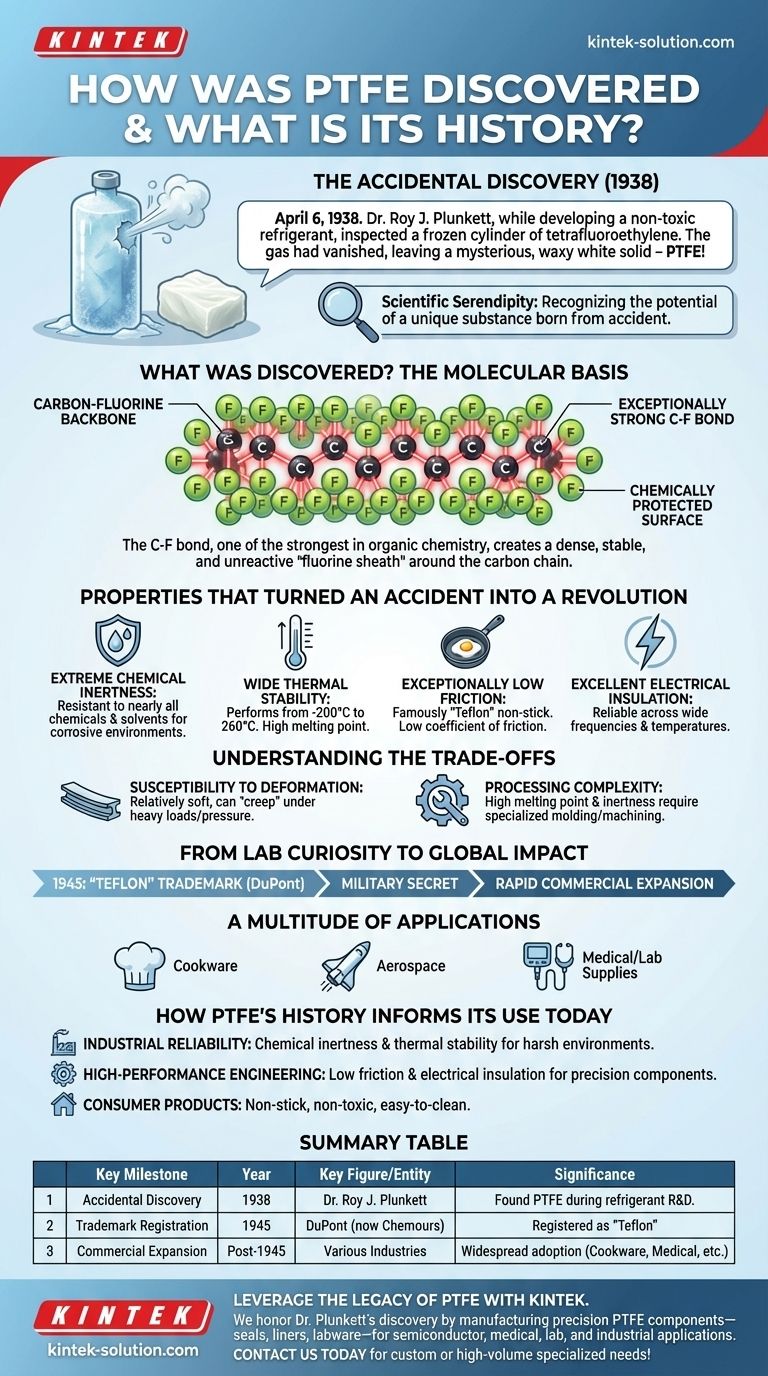

In a classic case of scientific serendipity, Polytetrafluoroethylene (PTFE) was discovered entirely by accident. On April 6, 1938, chemist Dr. Roy J. Plunkett was working to develop a new, non-toxic refrigerant when he inspected a frozen, pressurized cylinder of tetrafluoroethylene gas. He found that the gas had vanished, leaving behind a mysterious, waxy white solid that possessed remarkable properties.

The accidental discovery of PTFE is a story about recognizing potential. The material's true significance lies not in the accident itself, but in its unique molecular structure—the exceptionally strong carbon-fluorine bond—which gives it a combination of properties that were previously unattainable in a single substance.

What Exactly Was Discovered? The Molecular Basis of PTFE

The Carbon-Fluorine Backbone

PTFE is a fluoropolymer, a high-molecular-weight compound consisting of a long chain of carbon atoms.

What makes it unique is that this carbon backbone is completely sheathed in fluorine atoms.

The Strength of the Bond

The bond between carbon and fluorine atoms is one of the strongest known in organic chemistry.

This exceptional bond strength is the primary source of PTFE's durability, chemical inertness, and thermal stability. It creates a very dense, stable, and unreactive molecule.

A Chemically Protected Surface

The tightly packed fluorine atoms act as a protective shell around the carbon chain.

This "fluorine sheath" prevents other chemicals from reacting with the carbon backbone, rendering the material almost universally inert and giving it its famous non-stick, low-friction surface.

The Properties That Turned an Accident into a Revolution

Extreme Chemical Inertness

Because of its molecular structure, PTFE is resistant to nearly all chemicals and solvents.

This makes it an invaluable material for use in corrosive environments, from laboratory equipment to industrial pipes and vessels.

Wide Thermal Stability

PTFE performs reliably across an incredibly broad temperature range, from cryogenic lows (-200°C) up to high-heat applications (260°C).

Its high melting point and resistance to temperature changes allow it to be used where other plastics would fail.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, a property famously marketed under the brand name Teflon.

This "non-stick" quality is useful not only in cookware but also in creating low-friction bearings, gears, and other industrial parts.

Excellent Electrical Insulation

PTFE is an excellent electrical insulator, maintaining its properties across a wide range of frequencies and temperatures.

This has made it a critical component in electrical wiring, cables, and high-performance circuit boards.

Understanding the Trade-offs

Susceptibility to Deformation

While PTFE is highly flexible, this can also be a limitation.

It is a relatively soft material that can be damaged or deformed by heavy loads or high pressures, a phenomenon known as "creep."

Processing Complexity

The same chemical inertness and high melting point that make PTFE so useful also make it more difficult to process compared to conventional thermoplastics.

Specialized techniques are required to mold or machine it into finished parts.

From Lab Curiosity to Global Impact

The "Teflon" Brand

The material remained a military secret for several years before being registered under the Teflon trademark in 1945 by DuPont (now Chemours).

Its commercial use began to expand rapidly after it was introduced to the public.

A Multitude of Applications

The unique combination of properties has made PTFE indispensable across countless sectors.

Its applications range from non-stick cookware and stain-resistant fabrics to medical devices, aerospace components, and lab supplies.

How PTFE's History Informs Its Use Today

The accidental nature of its discovery highlights the importance of understanding a material's core properties to unlock its potential.

- If your primary focus is industrial reliability: The key takeaway is its unmatched chemical inertness and thermal stability for use in harsh, corrosive environments.

- If your primary focus is high-performance engineering: Its exceptionally low friction and excellent electrical insulation make it a premier choice for precision mechanical and electronic components.

- If your primary focus is consumer products: Its non-stick, non-toxic, and easy-to-clean surface properties are what drive its value and widespread adoption.

Ultimately, Dr. Plunkett's fortunate accident provided the world with one of its most versatile and foundational synthetic materials.

Summary Table:

| Key Milestone | Year | Key Figure/Entity | Significance |

|---|---|---|---|

| Accidental Discovery | 1938 | Dr. Roy J. Plunkett | Found a waxy white solid (PTFE) while developing a refrigerant |

| Trademark Registration | 1945 | DuPont (now Chemours) | Registered under the Teflon brand name |

| Commercial Expansion | Post-1945 | Various Industries | Widespread adoption in cookware, medical, aerospace, and more |

Leverage the Legacy of PTFE with KINTEK

Since its accidental discovery, PTFE has become indispensable for its chemical inertness, thermal stability, and low friction. At KINTEK, we honor this legacy by manufacturing precision PTFE components—including seals, liners, and labware—for semiconductor, medical, laboratory, and industrial applications. Whether you need custom prototypes or high-volume orders, our expertise ensures reliability in the most demanding environments.

Contact us today to discuss how our PTFE solutions can meet your specialized needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What makes PTFE suitable for chemical and pharmaceutical industries? Ensuring Purity and Performance in Critical Applications

- Is Teflon biodegradable and what are its environmental impacts? Understanding the 'Forever Material'

- How does PTFE react to ammonia? Discover Its Superior Chemical Resistance

- How is Teflon made? The Science Behind Its Incredible Properties

- What are some typical applications of PTFE? Leverage Its Unique Properties for Your Industry

- What are the industrial applications of Teflon's non-stick properties? Boost Efficiency & Prevent Buildup

- What is PTFE's biocompatibility and its medical applications? A Guide to Safe, Non-Reactive Medical Devices

- What is the volume resistivity and power factor of PTFE? Discover the Ultimate Electrical Insulator