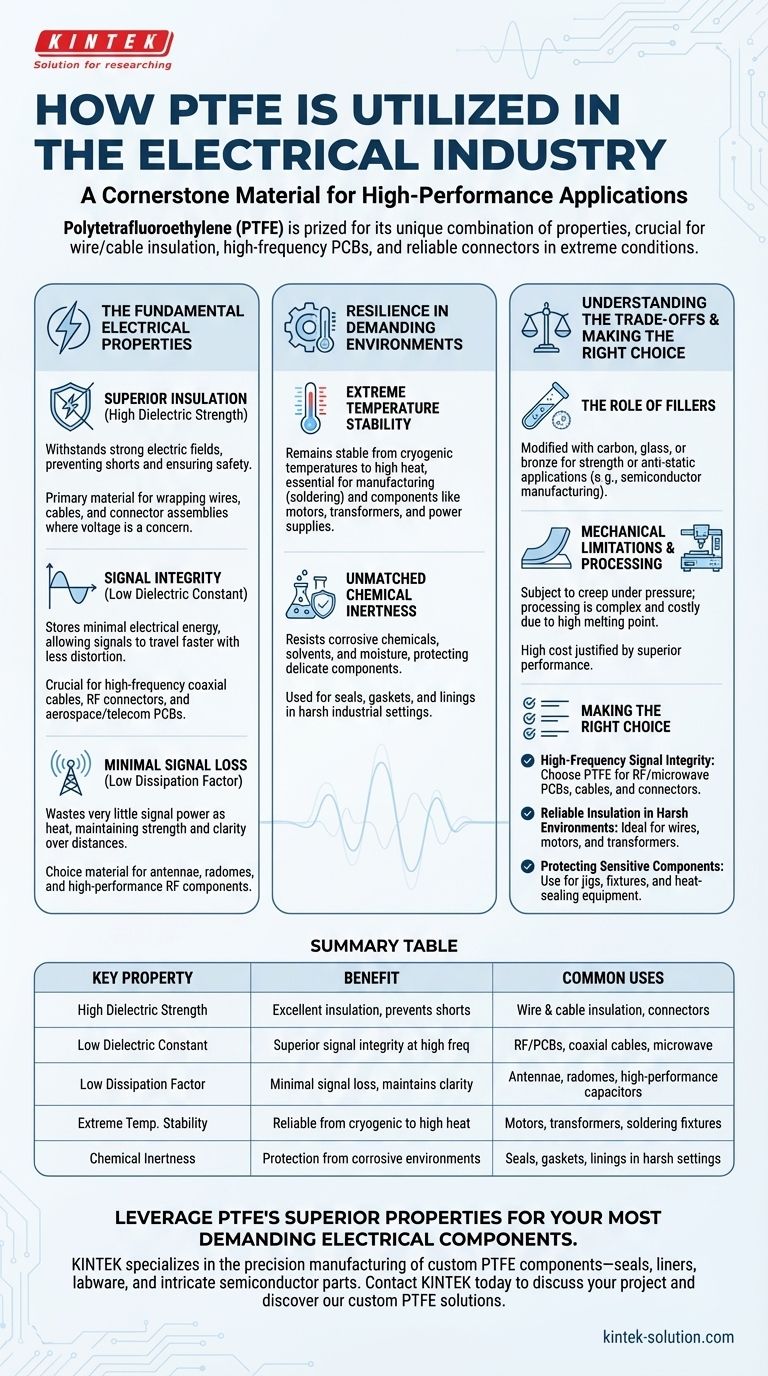

In the electrical and electronics industry, Polytetrafluoroethylene (PTFE) is a cornerstone material prized for its unique combination of properties. It is most commonly utilized for high-performance wire and cable insulation, manufacturing printed circuit boards (PCBs) for high-frequency applications, and fabricating connectors and semiconductor parts that must perform reliably under extreme conditions.

The core reason for PTFE's widespread use is not just its ability to insulate, but its exceptional performance at high frequencies and in harsh thermal and chemical environments. This makes it indispensable for mission-critical applications where signal integrity and long-term reliability are paramount.

The Fundamental Electrical Properties of PTFE

To understand PTFE's role, we must first look at its core electrical characteristics. These properties are what separate it from more common insulating materials.

Superior Insulation (High Dielectric Strength)

Dielectric strength is a measure of a material's ability to withstand a strong electric field without breaking down and conducting electricity.

PTFE possesses a very high dielectric strength, making it an extremely effective insulator. This property is critical for preventing short circuits and ensuring the safety and operational integrity of electrical components.

This is why it's a primary material for wrapping wires, cables, and connector assemblies, especially in applications where voltage is a concern.

Signal Integrity (Low Dielectric Constant)

A material's dielectric constant indicates its ability to store electrical energy in an electric field. For high-frequency applications, a low number is ideal.

PTFE has a very low dielectric constant, which means it doesn't absorb and store significant energy from the signals passing through it. This allows electrical signals to travel faster and with less distortion.

This characteristic is crucial for high-frequency coaxial cables, radio-frequency (RF) connectors, and printed circuit boards used in aerospace, telecommunications, and military systems.

Minimal Signal Loss (Low Dissipation Factor)

The dissipation factor, or loss tangent, measures how much of a signal's energy is lost as heat within the insulating material.

PTFE's exceptionally low dissipation factor ensures that very little signal power is wasted. This maintains signal strength and clarity, particularly over long distances or at microwave frequencies.

Because of this, PTFE is the material of choice for manufacturing antennae, radomes (radar domes), high-performance capacitors, and other critical RF components.

Resilience in Demanding Environments

Beyond its electrical performance, PTFE's physical robustness makes it suitable for applications where other materials would fail.

Extreme Temperature Stability

PTFE remains stable and effective across an incredibly wide temperature range. It can withstand the high temperatures required for manufacturing processes like soldering and heat sealing.

This thermal resilience also ensures reliability in components that generate significant heat, such as motors, transformers, and power supplies.

Unmatched Chemical Inertness

PTFE is almost completely inert, meaning it does not react with corrosive chemicals, solvents, or moisture.

This chemical resistance protects delicate electrical components from environmental damage, ensuring longevity and consistent performance. It's frequently used for seals, gaskets, and protective linings in harsh industrial settings.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not a universal solution. Acknowledging its limitations is key to using it effectively.

The Role of Fillers

Pure PTFE is one of the best insulators available. However, it can be modified with fillers like carbon, glass fiber, or bronze to alter its properties.

While this is often done to improve mechanical strength, some fillers can increase electrical conductivity. This turns PTFE from a pure insulator into a material for anti-static applications, a critical distinction in semiconductor manufacturing.

Mechanical Limitations

PTFE is a relatively soft material and is subject to "creep" or cold flow under sustained pressure. This means it is generally not suitable for high-load structural applications without reinforcement.

Processing and Cost

Due to its high melting point and unique molecular structure, processing PTFE is more complex and costly than molding common plastics like polyethylene or PVC. This higher cost is justified by its superior performance in applications where other materials are inadequate.

Making the Right Choice for Your Goal

Selecting the right material requires aligning its properties with your primary objective.

- If your primary focus is high-frequency signal integrity: PTFE's low dielectric constant and dissipation factor make it the superior choice for PCBs, coaxial cables, and connectors in RF and microwave systems.

- If your primary focus is reliable insulation in harsh environments: Its combination of high dielectric strength, temperature stability, and chemical inertness ensures long-term performance for wires, motors, and transformers.

- If your primary focus is protecting sensitive components during manufacturing: PTFE's non-reactive and non-stick surface is invaluable for jigs, fixtures, and heat-sealing equipment used in component assembly.

Ultimately, understanding PTFE's core properties allows you to leverage it not just as an insulator, but as a strategic component for ensuring performance and reliability in demanding electrical systems.

Summary Table:

| Key Property | Benefit for Electrical Applications | Common Uses |

|---|---|---|

| High Dielectric Strength | Excellent insulation, prevents short circuits | Wire & cable insulation, connectors |

| Low Dielectric Constant | Superior signal integrity at high frequencies | RF/PCBs, coaxial cables, microwave components |

| Low Dissipation Factor | Minimal signal loss, maintains clarity | Antennae, radomes, high-performance capacitors |

| Extreme Temperature Stability | Reliable performance from cryogenic to high heat | Motors, transformers, soldering fixtures |

| Chemical Inertness | Protection from corrosive environments | Seals, gaskets, linings in harsh settings |

Leverage PTFE's superior properties for your most demanding electrical components.

KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, labware, and intricate semiconductor parts—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures the material performance and reliability your critical applications demand.

Contact KINTEK today to discuss your project requirements and discover how our custom PTFE solutions can enhance your product's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How does Teflon's low surface energy contribute to its properties? The Science Behind Non-Stick & Low Friction

- What is the coefficient of friction (COF) and why is it important? Master Efficiency, Longevity, and Control

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What are the temperature properties of PTFE? From -268°C to 260°C, a Guide to Extreme Thermal Stability

- What are the advantages of using filled PTFE materials? Enhance Strength, Wear, and Stability

- How is PTFE produced? From TFE Gas to High-Performance Polymer

- What makes PTFE useful for non-stick applications? The Science Behind Its Slick Surface

- What are the key properties of PTFE? Unmatched Performance for Extreme Industrial Environments