At its core, PTFE (polytetrafluoroethylene) is defined by its exceptional thermal stability. It has a remarkably wide operating temperature range, maintaining its strength and toughness from cryogenic lows of -268°C (-450°F) up to a continuous service temperature of 260°C (500°F). Its crystalline melting point is significantly higher, around 327°C (620°F).

The crucial takeaway is not a single temperature but PTFE's remarkable consistency across a vast thermal spectrum. Its ability to maintain its essential properties from near absolute zero to high heat makes it one of the most versatile polymers for extreme environmental conditions.

Deconstructing PTFE's Thermal Performance

To properly evaluate PTFE, you must understand several distinct temperature thresholds. Each one defines a different aspect of its performance and limitations.

The Continuous Service Limit

The most important figure for any practical application is the maximum continuous service temperature, which for PTFE is 260°C (500°F).

Up to this point, the material reliably maintains its physical structure, molecular properties, and chemical inertness without significant degradation. This is the ceiling for long-term, reliable use.

The Melting Point

PTFE has a crystalline melting point of approximately 327°C (620°F).

At this temperature, the material transitions from a solid to a gel-like state, losing all structural integrity. It is critical to distinguish this from the service temperature; the material is no longer functional long before it reaches its melting point.

The Decomposition Threshold

At temperatures above 650°C (1200°F), PTFE undergoes depolymerization, breaking down its molecular structure.

However, a more immediate concern is the release of potentially hazardous fumes as temperatures begin to exceed its service limit of 260°C. This phenomenon, known as polymer fume fever, is a critical safety consideration in applications like cookware or industrial processing.

Cryogenic Resilience

PTFE's performance at low temperatures is just as impressive as its high-temperature stability.

It maintains high strength, toughness, and its self-lubricating properties at temperatures as low as -268°C (-450°F). Unlike many plastics that become extremely brittle and fail in cryogenic conditions, PTFE remains a viable material.

Key Thermal Properties and Their Implications

Beyond the primary temperature limits, other thermal properties dictate how PTFE behaves in a real-world assembly.

Thermal Conductivity

PTFE is an excellent thermal insulator, with a low thermal conductivity of approximately 0.25 W/m·K.

This means it resists the flow of heat. This property is highly desirable for electrical wire insulation or as a thermal break between components in an assembly.

Coefficient of Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion (around 100-160 x10⁻⁶ K⁻¹).

In practical terms, this means it expands and contracts significantly more than metals when the temperature changes. This is a critical design factor, as a mismatch in expansion can create immense stress and cause failure in tightly-fitted assemblies.

Heat Deflection Temperature

The heat deflection temperature reveals how PTFE behaves under mechanical load as it gets warmer.

Its ability to resist deformation drops significantly under load, to as low as 54°C (129°F) at 1.8 MPa of pressure. This is much lower than its 260°C service temperature and is a common source of design failure.

Understanding the Practical Trade-offs

No material is perfect. Acknowledging PTFE's limitations is key to successful implementation.

High Thermal Expansion

The single greatest design challenge with PTFE is its high thermal expansion. When designing components that mate with metal parts, you must account for this differential expansion to prevent stress, warping, or seal failure.

Load-Bearing Capacity at High Temperatures

While PTFE can exist at 260°C, its strength and ability to carry a mechanical load diminish significantly as temperatures rise. If your application involves both heat and pressure, you must design based on the heat deflection temperature, not the maximum service temperature.

Safety Above the Service Limit

Although PTFE is nonflammable, heating it beyond its recommended service temperature can release toxic particulates and gases. Proper ventilation and temperature control are essential in any application where overheating is a possibility.

Making the Right Choice for Your Application

Use these guidelines to determine if PTFE's thermal profile fits your specific goal.

- If your primary focus is extreme environmental stability: PTFE is an elite choice for applications requiring performance in both cryogenic and high-heat conditions where mechanical loads are low.

- If your primary focus is high-temperature mechanical performance: You must design according to PTFE's heat deflection temperature, as its load-bearing capacity is much lower than its simple temperature resistance.

- If your primary focus is precision assemblies with mixed materials: You must make its high coefficient of thermal expansion a central part of your design calculations to avoid failure from thermal stress.

By understanding these distinct thermal properties and their practical implications, you can confidently leverage PTFE's unique stability for the most demanding applications.

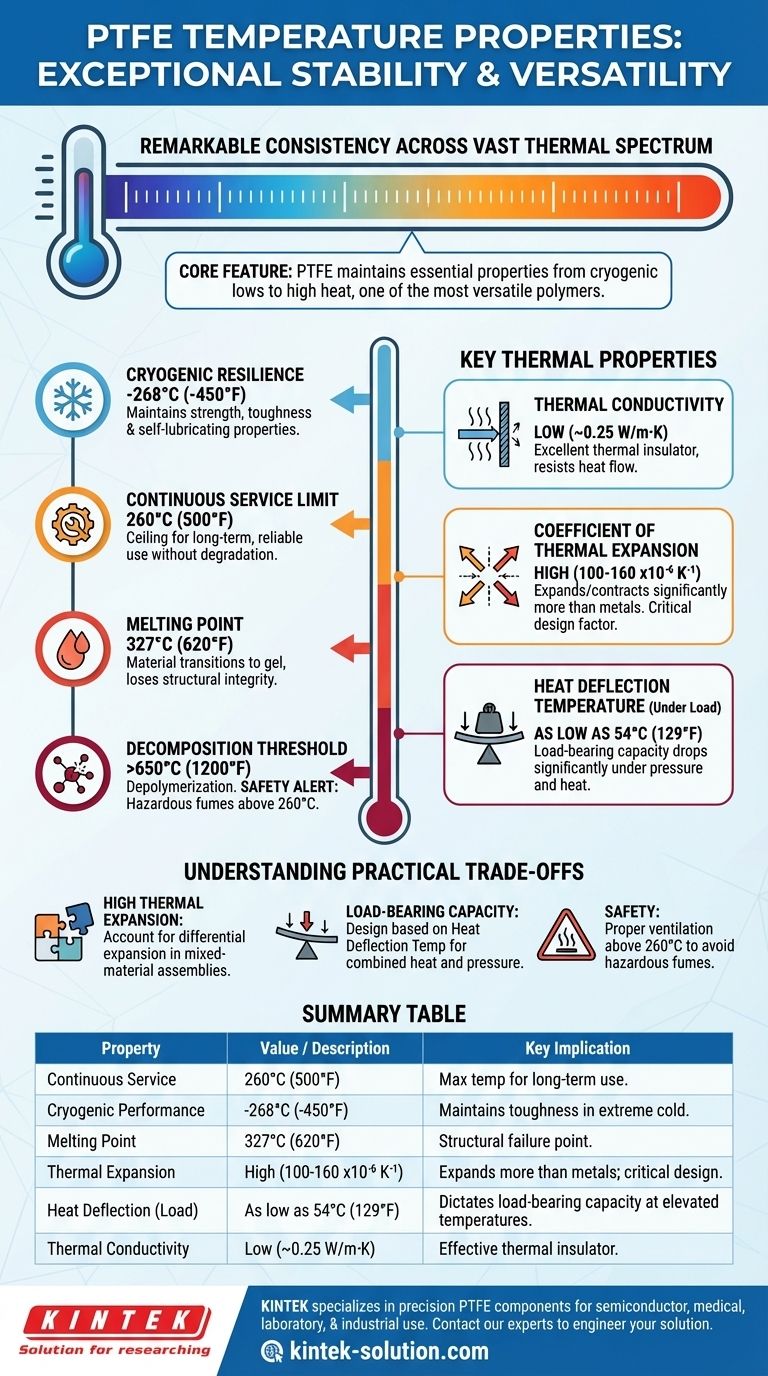

Summary Table:

| Property | Value / Description | Key Implication |

|---|---|---|

| Continuous Service Temperature | Up to 260°C (500°F) | Maximum temperature for long-term, reliable use without degradation. |

| Cryogenic Performance | Down to -268°C (-450°F) | Maintains toughness and strength in extreme cold, unlike many plastics. |

| Melting Point | 327°C (620°F) | Material loses structural integrity; not a functional limit. |

| Coefficient of Thermal Expansion | High (100-160 x10⁻⁶ K⁻¹) | Expands/contracts more than metals; a critical design factor for assemblies. |

| Heat Deflection Temperature (under load) | As low as 54°C (129°F) | Dictates load-bearing capacity at elevated temperatures; often the real design limit. |

| Thermal Conductivity | Low (~0.25 W/m·K) | Acts as an effective thermal insulator. |

Need High-Performance PTFE Components for Demanding Environments?

PTFE's exceptional thermal stability makes it ideal for semiconductor, medical, laboratory, and industrial applications. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—that perform reliably from cryogenic conditions to high-heat environments.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your components are designed to manage thermal expansion and mechanical loads correctly.

Let's engineer a solution for your specific thermal challenges. Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability