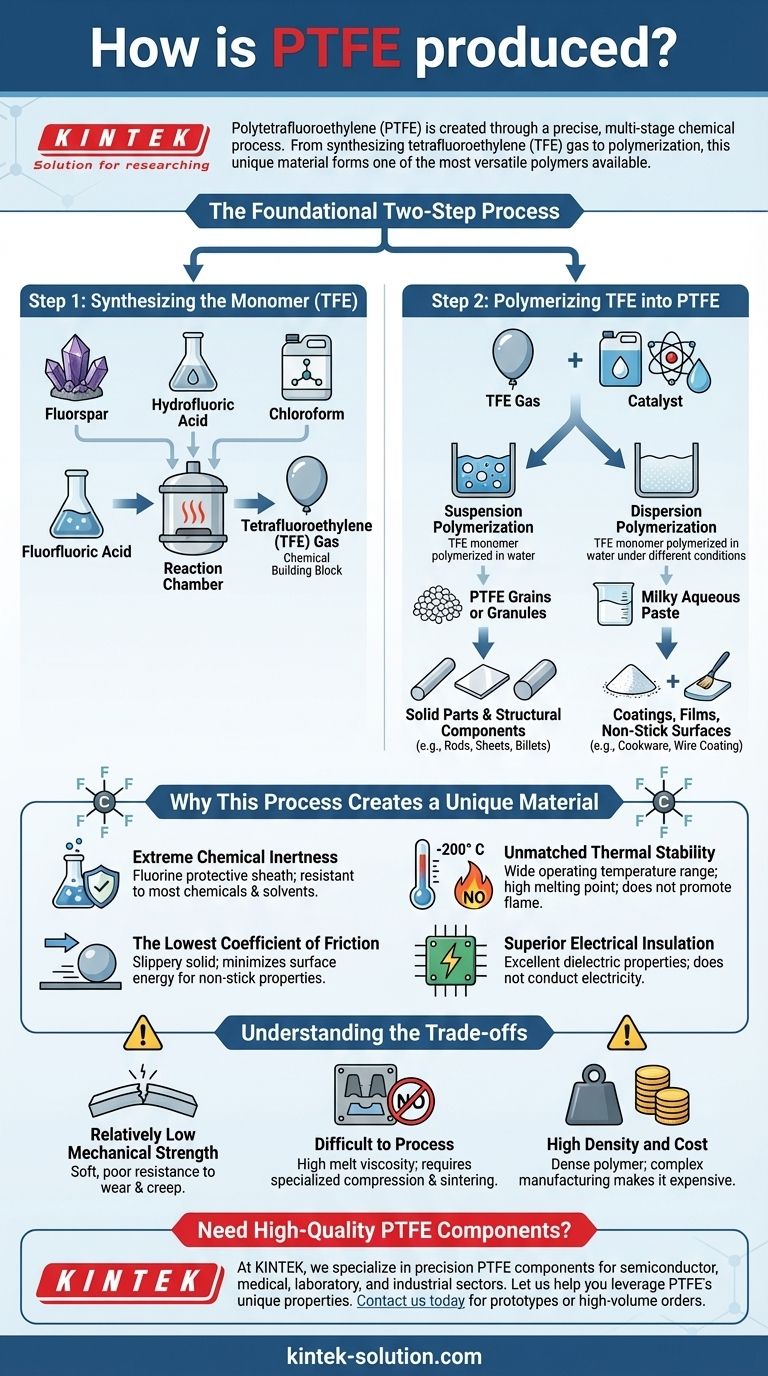

Polytetrafluoroethylene (PTFE) is created through a precise, multi-stage chemical process that begins with common industrial chemicals and ends with one of the most versatile polymers available. The core process involves synthesizing tetrafluoroethylene (TFE) gas from raw materials like fluorspar and chloroform. This TFE monomer is then polymerized in water using one of two primary methods to form the stable, long-chain polymer we know as PTFE.

The specific manufacturing method used—either suspension or dispersion polymerization—is the critical factor that determines the final physical form of the PTFE, directly shaping whether it becomes a solid part or a surface coating.

The Foundational Two-Step Process

At its core, all PTFE production follows the same fundamental path: create the monomer, then link those monomers into a polymer. Each step is carefully controlled to produce the final material.

Step 1: Synthesizing the Monomer (TFE)

The entire process begins by creating the chemical building block, a gas called tetrafluoroethylene (TFE).

This is achieved by heating raw materials such as fluorspar, hydrofluoric acid, and chloroform in a chemical reaction chamber. This reaction synthesizes the TFE gas, which is the foundational monomer for PTFE.

Step 2: Polymerizing TFE into PTFE

Once the TFE gas is created, it must be linked together into long, stable chains—a process called polymerization.

The TFE is introduced into water containing an iron catalyst, which initiates the polymerization reaction. This is where the process splits into two distinct paths, defining the final form and use of the material.

The Two Paths of Polymerization

The choice of polymerization method is not arbitrary; it is a deliberate decision made to produce PTFE with properties tailored for specific applications.

Suspension Polymerization

In this method, the TFE monomer is polymerized in water, resulting in the formation of solid PTFE grains or granules.

These grains are then typically processed and molded into solid forms like rods, sheets, and billets. This is the path for creating physical, structural components from PTFE.

Dispersion Polymerization

This method also polymerizes TFE in water but under different conditions, yielding a completely different output.

The result is a milky, aqueous paste. This paste can be processed further to create a fine powder. Both the paste and powder forms are ideal for creating coatings and films, such as the non-stick layer on cookware.

Why This Process Creates a Unique Material

The strength of the carbon-fluorine bond formed during polymerization is the source of PTFE's legendary properties. This simple but powerful molecular structure gives rise to a combination of characteristics unmatched by other polymers.

Extreme Chemical Inertness

The fluorine atoms form a protective, non-reactive sheath around the carbon backbone of the polymer chain. This makes PTFE resistant to nearly all industrial chemicals and solvents.

Unmatched Thermal Stability

The molecular structure is exceptionally stable, giving PTFE a very wide operating temperature range, typically from –200° C to +260° C. It has a high melting point of around 327°C and does not promote flame spread.

The Lowest Coefficient of Friction

Often cited as the most slippery solid material known, the smooth molecular profile of PTFE minimizes surface energy. This results in its famous non-stick and low-friction properties.

Superior Electrical Insulation

PTFE does not conduct electricity and possesses outstanding dielectric properties. This makes it one of the best insulating materials available, widely used in high-performance wiring and electronics.

Understanding the Trade-offs

No material is perfect, and for all its strengths, PTFE has inherent limitations that are a direct result of its molecular structure.

Relatively Low Mechanical Strength

Compared to other engineering plastics, PTFE is soft and has poor resistance to wear and creep (deformation under load). It is not suitable for high-load structural applications without reinforcement.

Difficult to Process

PTFE's high melting point and extremely high melt viscosity make it impossible to process using conventional techniques like injection molding. It must be molded using specialized compression and sintering methods, similar to powdered metals.

High Density and Cost

PTFE is a dense polymer, making it heavier than many alternatives. This, combined with its complex manufacturing process, also makes it a relatively expensive material.

Making the Right Choice for Your Application

Your end goal will dictate which type of PTFE is required. The production method is the first and most important consideration.

- If your primary focus is creating solid parts or structural components: You need suspension-polymerized PTFE, which can be molded into billets, rods, and sheets.

- If your primary focus is applying a non-stick or protective surface: You need dispersion-polymerized PTFE, available as a paste or fine powder designed for coatings.

- If your primary focus is high-performance electrical insulation: Either form may be used, depending on whether you need a solid insulator (molded) or a flexible wire coating (dispersion).

Understanding the production path is the first step to correctly leveraging PTFE's remarkable properties for your specific engineering challenge.

Summary Table:

| Production Stage | Key Inputs | Key Outputs | Primary Use Cases |

|---|---|---|---|

| Monomer Synthesis | Fluorspar, Hydrofluoric Acid, Chloroform | Tetrafluoroethylene (TFE) Gas | N/A (Intermediate) |

| Suspension Polymerization | TFE Gas, Water, Iron Catalyst | PTFE Grains/Granules | Solid Parts (Rods, Sheets, Billets) |

| Dispersion Polymerization | TFE Gas, Water, Iron Catalyst | PTFE Paste/Powder | Coatings, Films, Non-Stick Surfaces |

Need High-Quality PTFE Components for Your Project?

At KINTEK, we specialize in manufacturing precision PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures you get the right PTFE solution, whether you need prototypes or high-volume orders.

Let us help you leverage PTFE's unique properties:

- Chemical Inertness: Resistant to virtually all industrial chemicals

- Thermal Stability: Performs from -200°C to +260°C

- Low Friction: Ideal for non-stick and low-wear applications

- Superior Insulation: Excellent dielectric properties for electronics

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications