Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer specified for advanced industrial applications due to a unique combination of properties not found in other materials. Its primary attributes are near-total chemical inertness, an extremely low coefficient of friction, excellent performance across a wide temperature range, and superior electrical insulation.

PTFE is not chosen for its mechanical strength but for its unrivaled ability to survive and perform in extreme operational environments. Its value lies in its stability and reliability where other plastics and even metals would quickly fail due to chemical attack, high temperatures, or friction.

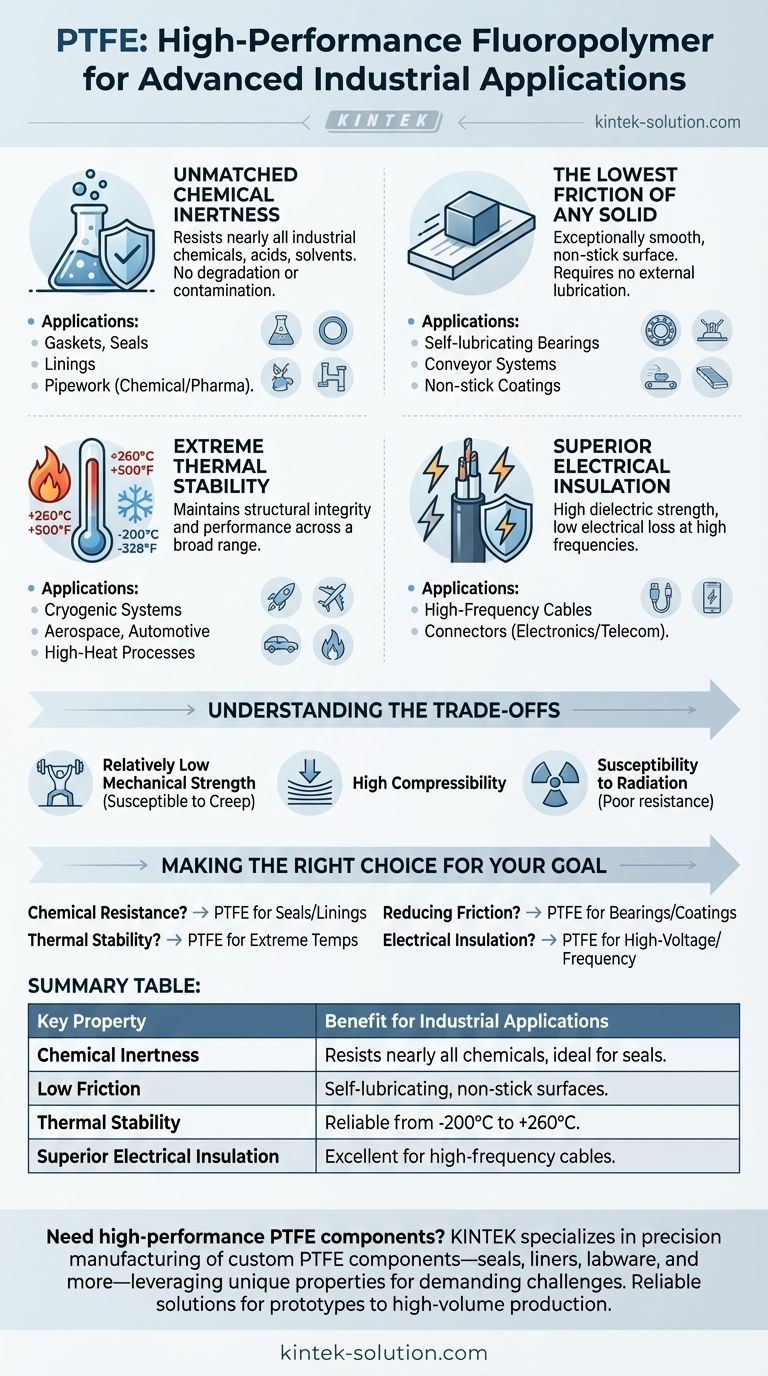

Why PTFE Excels in Demanding Environments

To understand PTFE's role in industry, we must look at how its core properties solve specific engineering challenges. Each characteristic makes it the default choice for a distinct set of problems.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and solvents. This inertness means it will not degrade, swell, or become contaminated when exposed to aggressive substances.

This makes it indispensable for components like gaskets, seals, linings, and pipework in the chemical processing and pharmaceutical industries, ensuring both equipment longevity and product purity.

The Lowest Friction of Any Solid

PTFE has one of the lowest coefficients of friction of any known solid material. This creates an exceptionally smooth, non-stick surface that requires no external lubrication.

This property is critical for applications like self-lubricating bearings, conveyor systems, and non-stick coatings where minimizing wear and ensuring smooth, effortless movement is essential.

Extreme Thermal Stability

The material maintains its structural integrity and performance characteristics across an exceptionally broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This thermal stability makes PTFE suitable for both cryogenic applications and high-temperature processes found in aerospace, automotive, and industrial manufacturing.

Superior Electrical Insulation

PTFE is an outstanding electrical insulator with high dielectric strength, meaning it can withstand very high voltages without breaking down. It also has very low electrical loss at high frequencies.

These characteristics make it a first-choice material for insulating high-frequency cables and connectors in the electronics and telecommunications industries, where signal integrity is paramount.

Understanding the Trade-offs

No material is perfect, and a trusted decision requires acknowledging a material's limitations. PTFE's unique strengths come with corresponding trade-offs in its mechanical properties.

Relatively Low Mechanical Strength

Compared to engineering plastics like Nylon or PEEK, PTFE is relatively soft. It can be susceptible to creep, which is the tendency to deform slowly under a constant load.

This means it is generally not suitable for high-load structural components unless it is reinforced with fillers like glass fiber or carbon.

High Compressibility

While PTFE exhibits good dimensional stability, it is also highly compressible. This can be an advantage for sealing applications but must be accounted for in designs requiring tight mechanical tolerances under pressure.

Susceptibility to Radiation

PTFE has poor resistance to high-energy radiation (such as gamma rays), which can cause the polymer chains to break down, leading to embrittlement and a loss of mechanical properties.

Making the Right Choice for Your Goal

Selecting PTFE should be a deliberate decision based on the most critical requirement of your application.

- If your primary focus is chemical resistance: PTFE is the definitive choice for seals, gaskets, and linings that will be exposed to aggressive chemicals.

- If your primary focus is reducing friction: Use PTFE for self-lubricating bearings, slide plates, or non-stick surface coatings where smooth movement is critical.

- If your primary focus is thermal stability: Select PTFE for components operating across extreme temperature ranges, from cryogenic systems to high-heat processing.

- If your primary focus is electrical insulation: PTFE is ideal for high-frequency or high-voltage applications where signal integrity and safety are paramount.

Ultimately, PTFE's value lies in its unique ability to provide consistent, reliable performance in conditions that cause conventional materials to degrade and fail.

Summary Table:

| Key Property | Benefit for Industrial Applications |

|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals, acids, and solvents. Ideal for seals and linings. |

| Low Coefficient of Friction | Provides self-lubricating, non-stick surfaces for bearings and conveyor systems. |

| Thermal Stability | Performs reliably from -200°C to +260°C, suitable for cryogenic and high-heat processes. |

| Superior Electrical Insulation | Excellent dielectric strength for high-frequency/high-voltage cables and connectors. |

Need high-performance PTFE components for your application?

KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, labware, and more—for the semiconductor, medical, laboratory, and industrial sectors. We leverage PTFE's unique properties to solve your most demanding challenges, from chemical resistance to thermal stability.

Whether you require prototypes or high-volume production, we deliver reliable solutions that perform in extreme environments.

Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers