At its core, Polytetrafluoroethylene (PTFE) is uniquely useful for non-stick applications because of its molecular structure. The exceptionally strong bonds between its carbon and fluorine atoms create a chemically inert and low-energy surface, which results in an extremely low coefficient of friction that prevents other substances from adhering to it.

The non-stick quality of PTFE is not just a surface treatment; it is an intrinsic property of the material itself. A tight "sheath" of fluorine atoms creates a non-reactive barrier that other molecules simply cannot find a way to bond with, causing them to slide off.

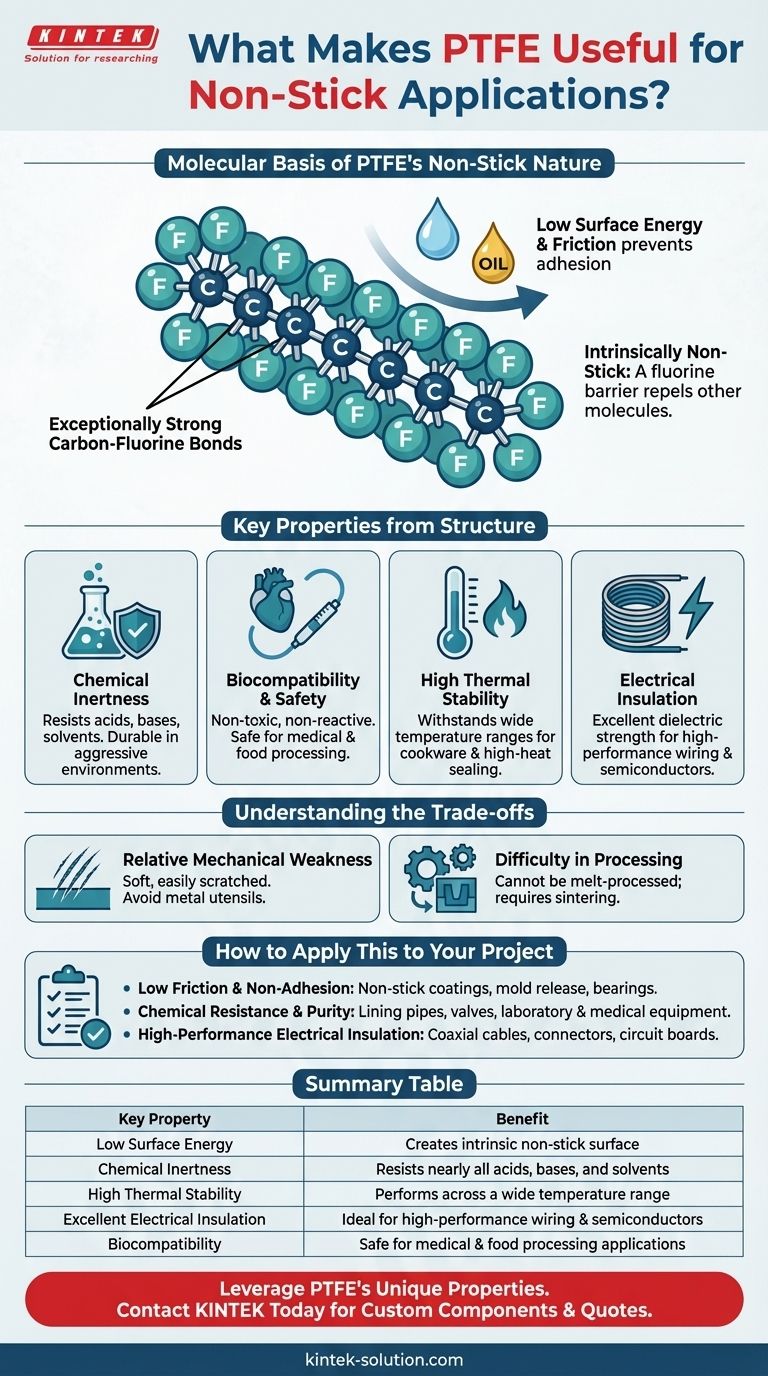

The Molecular Basis of PTFE's Non-Stick Nature

To truly understand PTFE's non-stick capability, we must look at its atomic composition. The properties that make it famous are a direct result of its simple but powerful molecular architecture.

The Strength of the Carbon-Fluorine Bond

PTFE is a polymer made of a long chain of carbon atoms, where each carbon is bonded to two fluorine atoms. The bond between carbon and fluorine is one of the strongest single bonds in organic chemistry.

This incredible bond strength makes the molecule extremely stable and non-reactive.

The Fluorine Sheath

The fluorine atoms are larger than the carbon atoms they are attached to. They effectively wrap around the carbon backbone, creating a dense, uniform, and seamless outer shell or "sheath."

This protective fluorine sheath shields the more reactive carbon chain from interacting with outside substances.

Extremely Low Surface Energy

Because of this stable fluorine sheath, the surface of PTFE has incredibly low energy. For one material to stick to another, there must be some form of intermolecular attraction or chemical bonding.

The PTFE surface offers virtually nothing for other molecules to "grab" onto. This fundamental repulsion is what we perceive as its exceptional non-stick and low-friction characteristic.

Key Properties Stemming From Its Structure

The same molecular structure that creates the non-stick effect gives rise to several other highly valuable properties that expand its use far beyond cookware.

Unmatched Chemical Inertness

The strong carbon-fluorine bonds are incredibly difficult for other chemicals to break. This makes PTFE resistant to nearly all corrosive chemicals, acids, and bases.

This property ensures its durability and integrity in aggressive chemical environments.

Biocompatibility and Safety

PTFE's chemical inertness also means it is non-toxic and biocompatible. It does not react with biological tissues or fluids within the body.

This makes it a trusted material for life-saving medical equipment, including catheters, sutures, and bio-containment vessels. It is also FDA-approved for use in food processing equipment.

High Thermal Stability

The material's stable molecular structure allows it to withstand a wide range of temperatures, a crucial characteristic for its use in non-stick cookware and as a sealing material in high-heat applications.

Electrical Insulation

The same tightly-held electrons that prevent chemical reactions also make PTFE an excellent electrical insulator. It has a high dielectric strength, meaning it can withstand high voltages without breaking down.

This makes it essential for insulating high-performance wiring, such as data cables and components in semiconductors.

Understanding the Trade-offs

No material is perfect, and its greatest strengths often create inherent limitations. Understanding these is key to using PTFE effectively.

Relative Mechanical Weakness

While chemically robust, PTFE is a relatively soft material. It has poor resistance to abrasion and can be easily scratched, which is why metal utensils are discouraged on non-stick pans.

Difficulty in Processing

The same inertness that makes PTFE so useful also makes it difficult to process. It cannot be melt-processed like most common plastics, requiring more complex and costly manufacturing techniques like sintering.

How to Apply This to Your Project

Choosing a material depends entirely on the primary problem you need to solve. PTFE's unique profile makes it the definitive choice for specific challenges.

- If your primary focus is low friction and non-adhesion: PTFE is the unparalleled choice for applications like non-stick coatings, mold release surfaces, and low-friction bearings.

- If your primary focus is chemical resistance and purity: Its inertness makes it ideal for lining pipes, valves, and vessels in the chemical industry or for laboratory and medical equipment.

- If your primary focus is high-performance electrical insulation: PTFE is a critical material for coaxial cables, connectors, and circuit boards where signal integrity and safety are paramount.

By understanding the fundamental molecular properties of PTFE, you can leverage its powerful characteristics to solve a wide range of engineering challenges.

Summary Table:

| Key Property | Benefit |

|---|---|

| Low Surface Energy | Creates an intrinsic non-stick surface |

| Chemical Inertness | Resists nearly all acids, bases, and solvents |

| High Thermal Stability | Performs across a wide temperature range |

| Excellent Electrical Insulation | Ideal for high-performance wiring and semiconductors |

| Biocompatibility | Safe for medical and food processing applications |

Leverage PTFE's unique properties for your project. KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we deliver the chemical resistance and performance you require.

Contact KINTEK today to discuss your application and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications