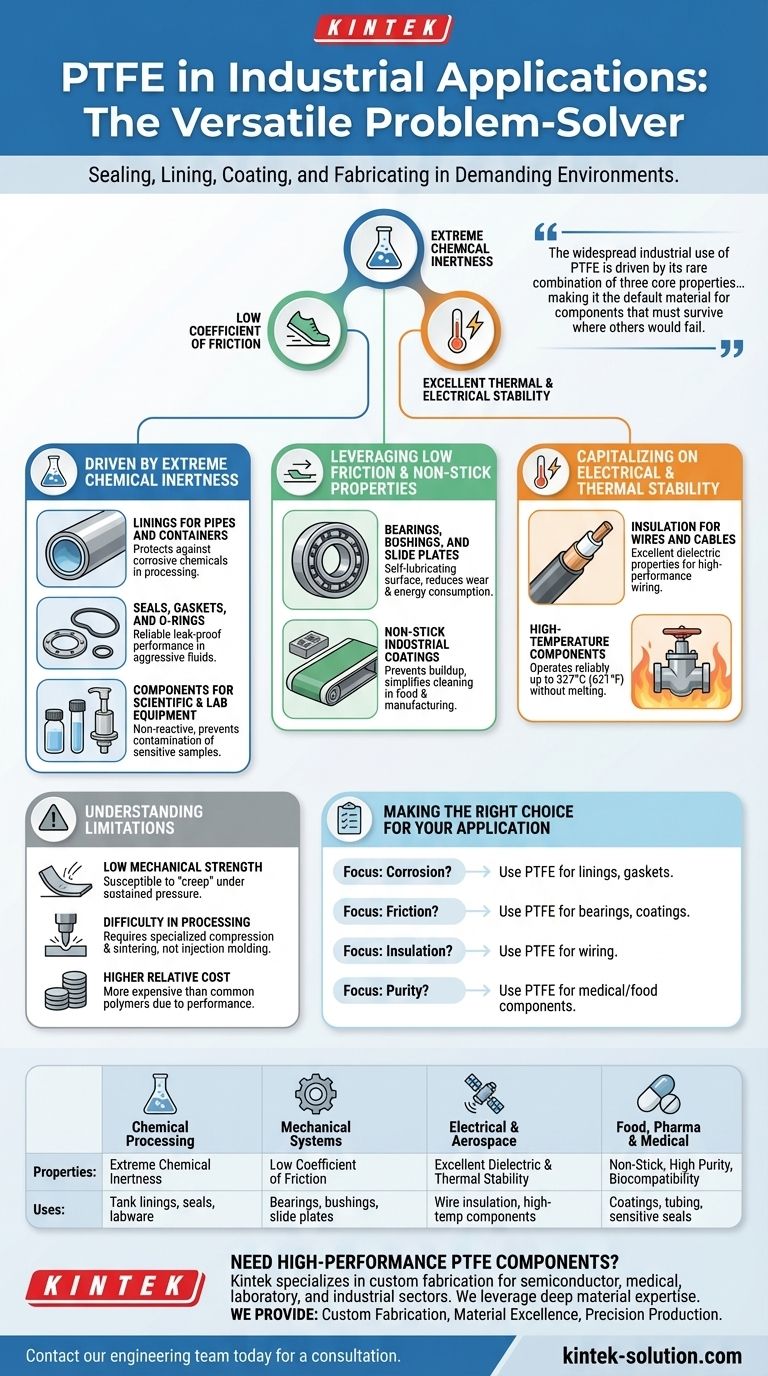

In industrial settings, Polytetrafluoroethylene (PTFE) is a uniquely versatile problem-solver used for sealing, lining, coating, and fabricating components in chemically aggressive, high-temperature, or low-friction environments. Its applications range from creating non-stick surfaces and chemically inert seals to insulating high-performance wiring in aerospace and electronics.

The widespread industrial use of PTFE is driven by its rare combination of three core properties: extreme chemical inertness, an exceptionally low coefficient of friction, and excellent thermal and electrical resistance. This makes it the default material for components that must survive where others would fail.

Driven by Extreme Chemical Inertness

One of the most valuable properties of PTFE is its near-total immunity to chemical attack. This makes it indispensable in industries that handle corrosive or reactive substances.

Linings for Pipes and Containers

PTFE is frequently used to line vessels, pipes, and tanks in chemical processing plants. This protective layer prevents highly corrosive chemicals from degrading the underlying metal structure.

Seals, Gaskets, and O-Rings

In any system handling aggressive fluids, creating a reliable seal is critical. PTFE gaskets, seals, and O-rings provide this reliability, ensuring leak-proof performance in environments where traditional elastomers would quickly disintegrate. This includes applications in chemical transport and processing equipment.

Components for Scientific and Lab Equipment

In high-purity environments like pharmaceutical research and chromatography, PTFE's non-reactive nature is essential. It is used for sealing vials, tubing, and pump parts because it will not contaminate sensitive APIs, biologics, or test samples.

Leveraging Low Friction and Non-Stick Properties

PTFE has one of the lowest coefficients of friction of any known solid, often compared to wet ice on wet ice. This property is foundational to its use in mechanical and coating applications.

Bearings, Bushings, and Slide Plates

For moving parts where lubrication is difficult or undesirable, PTFE bearings and bushings provide a self-lubricating surface. This reduces wear, minimizes energy consumption, and ensures smooth operation in gears and slide plates.

Non-Stick Industrial Coatings

While famous for its use in cookware, this non-stick property is vital in industry. Equipment used in food and beverage processing or manufacturing is often coated with PTFE to prevent material buildup, simplify cleaning, and improve efficiency.

Capitalizing on Electrical and Thermal Stability

PTFE is an outstanding electrical insulator and maintains its stability across a wide range of temperatures, from cryogenic levels up to its high melting point of around 327°C (621°F).

Insulation for Wires and Cables

Due to its excellent dielectric properties, PTFE is a preferred insulator for high-performance wiring. It is commonly found in computer applications like coaxial cables and critical wiring harnesses within aircraft, where signal integrity and fire resistance are paramount.

High-Temperature Components

Components that must operate reliably at high temperatures, such as specific valve and pump parts, are often made from PTFE. It provides a stable material solution that will not melt or degrade under significant thermal stress.

Understanding the Limitations of PTFE

While immensely useful, PTFE is not a universal solution. Understanding its trade-offs is key to successful application.

Low Mechanical Strength

Compared to other engineering plastics, PTFE is relatively soft and has poor resistance to "creep" or cold flow. Under sustained pressure, it can deform, which must be accounted for in structural designs.

Difficulty in Processing

PTFE cannot be melt-processed using conventional techniques like injection molding. It must be machined from stock shapes or formed through a specialized process of compression and sintering, which can increase manufacturing complexity and cost.

Higher Relative Cost

As a high-performance fluoropolymer, PTFE is significantly more expensive than common polymers like polyethylene or polypropylene. Its use is typically justified by performance requirements that other materials cannot meet.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary challenge you need to solve.

- If your primary focus is corrosion resistance: PTFE is an industry-standard choice for lining pipes, tanks, and creating gaskets for handling reactive chemicals.

- If your primary focus is reducing friction: Use PTFE for bearings, slide plates, or as a surface coating where low-wear, self-lubricating performance is required.

- If your primary focus is electrical insulation: PTFE is a superior material for high-frequency or high-temperature wiring where signal integrity is critical.

- If your primary focus is purity or biocompatibility: Its inertness makes PTFE ideal for components in medical, pharmaceutical, and food processing equipment.

Ultimately, PTFE's value lies in its ability to provide reliable performance in the most demanding operational environments.

Summary Table:

| Application Category | Key PTFE Properties Utilized | Common Industrial Uses |

|---|---|---|

| Chemical Processing | Extreme Chemical Inertness | Tank linings, pipe linings, seals, gaskets, labware |

| Mechanical Systems | Low Coefficient of Friction | Self-lubricating bearings, bushings, slide plates |

| Electrical & Aerospace | Excellent Dielectric & Thermal Stability | Wire insulation, cable jackets, high-temp components |

| Food, Pharma & Medical | Non-Stick, High Purity, Biocompatibility | Non-stick coatings, tubing, seals for sensitive processes |

Need High-Performance PTFE Components for Your Demanding Application?

KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, labware, and complex fabricated parts—for the semiconductor, medical, laboratory, and industrial sectors. We leverage deep material expertise to ensure your components deliver unmatched chemical resistance, low friction, and thermal stability.

We provide:

- Custom Fabrication: From prototypes to high-volume production runs.

- Material Excellence: Components built to perform in aggressive, high-purity, or high-temperature environments.

- Precision Production: Meeting the tightest tolerances for critical applications.

Let us help you solve your most challenging material problems. Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications