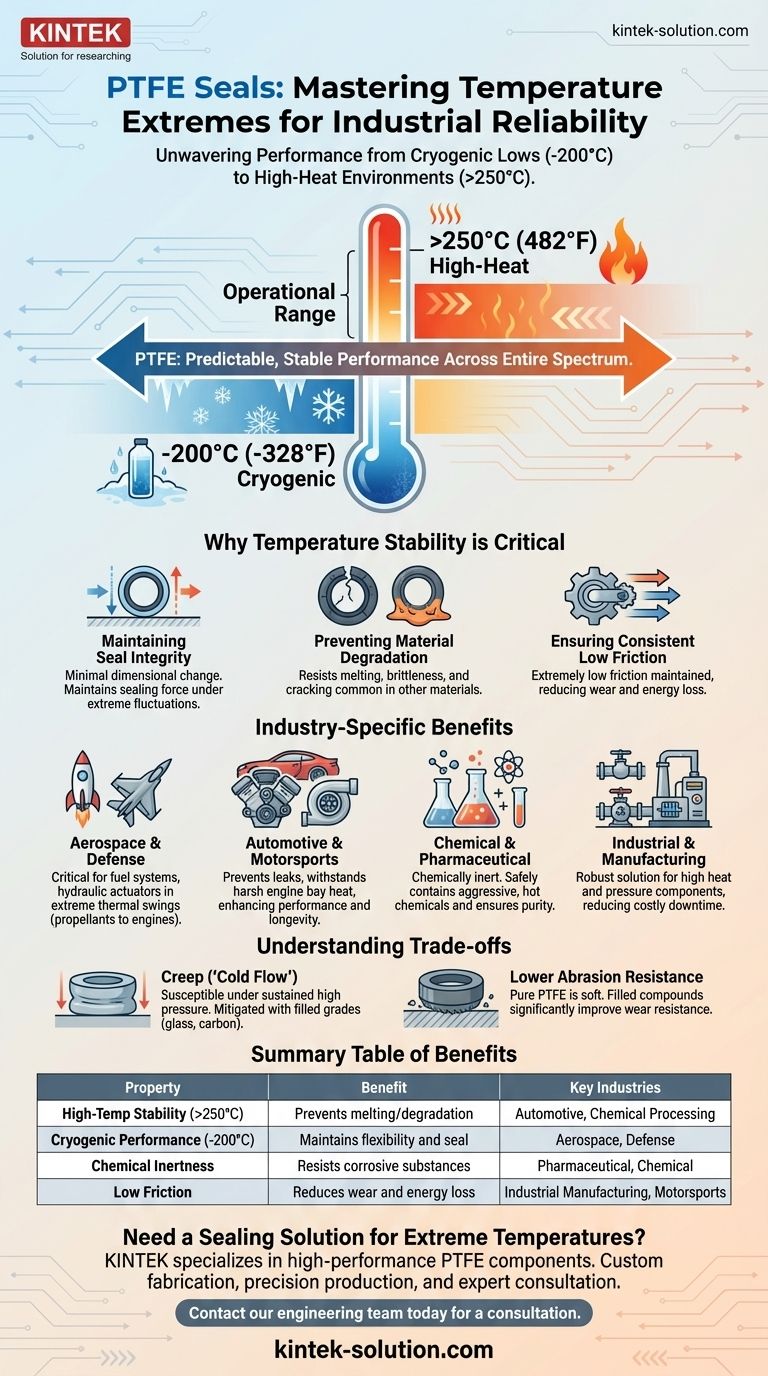

The fundamental benefit of PTFE's temperature range is its unwavering reliability in conditions where other materials fail. Polytetrafluoroethylene (PTFE) seals maintain their structural integrity and sealing performance across an exceptionally broad thermal spectrum, from cryogenic lows around -200°C (-328°F) to high-heat environments exceeding 250°C (482°F). This stability makes them indispensable in demanding industries like aerospace, automotive, and chemical processing.

The true value of PTFE's temperature range isn't just its ability to survive extreme conditions; it's the predictable, stable performance it guarantees. This consistency prevents catastrophic failures and enables innovation in applications where other sealing materials would degrade, crack, or melt.

Why Temperature Stability is a Critical Sealing Property

A seal's primary job is to prevent leaks by maintaining a constant force against a surface. Extreme temperature fluctuations directly challenge this function, but PTFE is uniquely engineered to withstand them.

Maintaining Seal Integrity

All materials expand with heat and contract with cold. A material with poor thermal stability will change its dimensions dramatically, compromising the seal.

PTFE's molecular structure is incredibly stable, allowing it to maintain its shape and sealing force with minimal variation across its entire operational temperature range.

Preventing Material Degradation

High temperatures can cause common elastomers like rubber to soften, melt, or become brittle. Extreme cold can cause them to harden and crack.

PTFE resists both of these failure modes. It does not melt below its high threshold and remains flexible even at cryogenic temperatures, ensuring it continues to function as an effective seal.

Ensuring Consistent Low Friction

One of PTFE's signature properties is its extremely low coefficient of friction.

Crucially, this "slipperiness" is maintained even at very high or low temperatures. This reduces energy loss and wear on moving parts in systems like engines or actuators, regardless of the thermal environment.

Industry-Specific Benefits of Thermal Range

The ability to perform reliably at temperature extremes unlocks critical applications across several high-stakes industries.

Aerospace and Defense

Aerospace environments represent the ultimate thermal challenge, from the cryogenic temperatures of liquid rocket propellants to the intense heat of engine components.

PTFE seals are essential for ensuring the integrity of fuel systems, hydraulic actuators, and other mission-critical components that experience these vast temperature swings.

Automotive and Motorsports

Modern engines, transmissions, and turbochargers operate at consistently high temperatures.

PTFE seals prevent fluid leaks and withstand the harsh thermal environment inside an engine bay, providing a durable, long-lasting solution that reduces maintenance and enhances performance.

Chemical and Pharmaceutical Processing

Many chemical reactions occur at elevated temperatures and involve highly corrosive substances.

PTFE is not only temperature-resistant but also nearly universally inert. This dual capability makes its seals the standard for safely containing aggressive chemicals, even when heated, protecting both equipment and product purity.

Industrial and Manufacturing

Components like pumps, valves, and compressors in industrial settings often operate under high heat and pressure.

Using PTFE seals provides a versatile and robust solution that enhances equipment longevity and reduces costly downtime due to seal failure.

Understanding the Trade-offs

While its thermal range is exceptional, PTFE is not a universal solution. Understanding its limitations is key to proper application.

Creep or "Cold Flow"

Under sustained pressure, especially at the higher end of its temperature range, PTFE can be susceptible to "creep"—a slow, permanent deformation.

For high-pressure applications, this is often mitigated by using filled PTFE grades, where materials like glass, carbon, or graphite are added to enhance compressive strength.

Lower Abrasion Resistance

In its pure (virgin) form, PTFE is relatively soft and can wear in applications with high friction against rough surfaces.

Again, filled PTFE compounds are used to significantly improve wear and abrasion resistance, tailoring the seal to more demanding mechanical duties.

Making the Right Choice for Your Goal

Your application's specific thermal demands will determine if PTFE is the optimal choice.

- If your primary focus is extreme cold and heat cycles (e.g., aerospace): The unparalleled thermal range of PTFE is non-negotiable for ensuring mission-critical reliability.

- If your primary focus is high-temperature chemical exposure (e.g., chemical processing): PTFE's combined thermal stability and chemical inertness provide the safest, most durable sealing solution available.

- If your primary focus is consistent performance in high-heat mechanical systems (e.g., automotive): PTFE's ability to maintain its seal integrity and low-friction properties at engine temperatures reduces wear and prevents leaks.

Ultimately, leveraging PTFE's thermal properties is about ensuring operational integrity under conditions that would cause lesser materials to fail.

Summary Table:

| Property | Benefit | Key Industries |

|---|---|---|

| High-Temp Stability (>250°C / 482°F) | Prevents melting/degradation | Automotive, Chemical Processing |

| Cryogenic Performance (-200°C / -328°F) | Maintains flexibility and seal | Aerospace, Defense |

| Chemical Inertness | Resists corrosive substances | Pharmaceutical, Chemical |

| Low Friction | Reduces wear and energy loss | Industrial Manufacturing, Motorsports |

Need a sealing solution for extreme temperatures?

PTFE's ability to perform reliably from -200°C to 250°C makes it indispensable for demanding applications. At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact seal your application requires.

Let's discuss how our PTFE expertise can enhance your project's reliability and performance. Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions