In short, the non-absorbent nature of PTFE Teflon washers is the cornerstone of their performance in demanding environments. This property means they completely resist moisture and other liquids, preventing the swelling, softening, and degradation that commonly plague other materials. As a result, they maintain their original shape and sealing capability, ensuring consistent and reliable function over time.

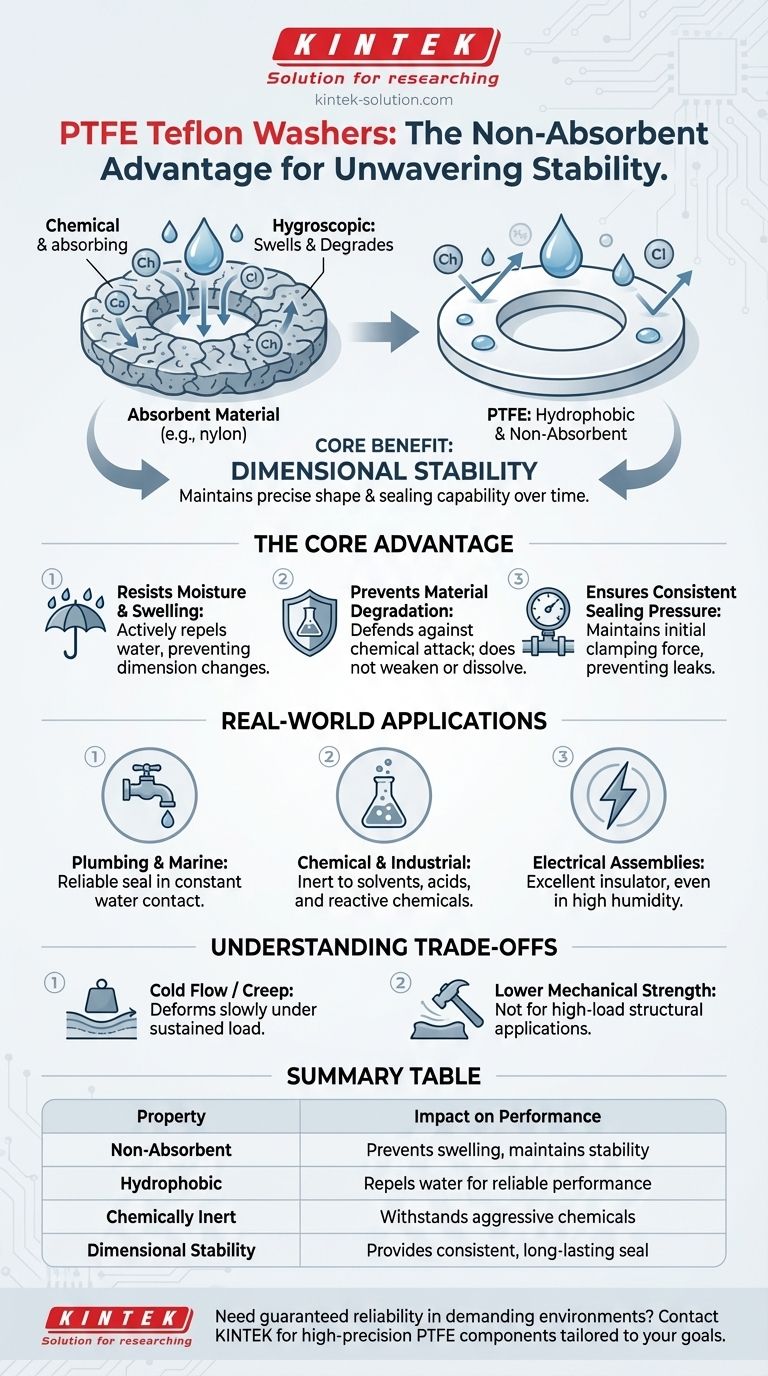

The core benefit of a non-absorbent washer is dimensional stability. Unlike materials that change shape with moisture, PTFE washers maintain their precise dimensions, ensuring a consistent and reliable seal throughout the component's entire service life.

The Core Advantage: Unwavering Stability

The term "non-absorbent" directly translates to predictable mechanical behavior. This stability is the key differentiator for PTFE in many applications where other materials would fail.

Resisting Moisture and Swelling

Many common sealing materials, like nylon or certain elastomers, are hygroscopic, meaning they absorb water from the air. This absorption causes them to swell, changing their dimensions and potentially compromising the seal's integrity.

PTFE is hydrophobic; it actively repels water. This guarantees that its size and shape remain constant, whether it is in a dry desert or submerged in water.

Preventing Material Degradation

When a material absorbs a liquid, it's not just a physical change. Aggressive chemicals can initiate a breakdown of the material's polymer chains, leading to a loss of strength and eventual failure.

Because PTFE does not absorb these fluids, it offers a superior defense against chemical attack, ensuring the washer does not weaken or dissolve over time.

Ensuring Consistent Sealing Pressure

A washer that swells or softens cannot maintain consistent pressure on the surfaces it is sealing. This loss of clamping force can lead to leaks, especially in systems with fluctuating pressure or temperature.

PTFE's stability ensures that the initial sealing pressure applied during installation is maintained throughout the life of the component.

Performance in Real-World Applications

The benefit of a non-absorbent material becomes clear when you consider the environments where these washers excel.

Plumbing and Marine Systems

In any application involving constant contact with water, PTFE washers provide a reliable seal that will not rot, degrade, or deform. This prevents leaks and extends the service life of fixtures and equipment.

Chemical and Industrial Processing

For systems handling solvents, acids, or other reactive chemicals, PTFE's non-absorbent and chemically inert properties are critical. The washer will not break down, nor will it absorb and contaminate the process fluid.

Electrical Assemblies

Moisture absorption can severely compromise the dielectric (insulating) properties of a material. PTFE's inability to absorb water ensures it remains an excellent electrical insulator, even in high-humidity conditions.

Understanding the Trade-offs

While its non-absorbent nature is a significant strength, no material is perfect. It is important to understand the complete performance profile of PTFE.

Susceptibility to Cold Flow

The primary trade-off for PTFE's excellent sealing capability is its tendency to "creep" or cold flow. Under sustained compressive load, the material can slowly deform over time. This must be accounted for in joint design, often by using engineered washers or proper torque specifications.

Relatively Low Mechanical Strength

Compared to metal or harder engineering plastics, PTFE is a soft material. This softness is what allows it to conform to surfaces to create a tight seal, but it also means it is unsuitable for high-load structural applications where compressive strength is the primary requirement.

Making the Right Choice for Your Goal

Selecting a washer depends entirely on the demands of your specific application.

- If your primary focus is reliability in wet or humid environments: PTFE's non-absorbent nature makes it the ideal choice to prevent swelling and degradation.

- If your primary focus is sealing aggressive chemicals: The combination of non-absorbency and chemical inertness ensures the washer will not break down or contaminate your system.

- If your primary focus is maintaining precise dimensions and a consistent seal: PTFE's dimensional stability provides a predictable and long-lasting fit where other materials would fail.

Ultimately, choosing a PTFE washer is a decision for predictable performance and long-term stability when environmental conditions are a critical factor.

Summary Table:

| Property | Impact on Performance |

|---|---|

| Non-Absorbent | Prevents swelling, maintains dimensional stability, and resists chemical degradation. |

| Hydrophobic | Repels water, ensuring reliable performance in wet or humid conditions. |

| Chemically Inert | Withstands aggressive chemicals without absorbing or contaminating fluids. |

| Dimensional Stability | Provides a consistent, reliable seal over the entire service life of the component. |

Need a sealing solution that guarantees reliability in demanding environments?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our PTFE washers are engineered to provide the dimensional stability and chemical resistance your application requires.

Whether you need prototypes or high-volume orders, our custom fabrication ensures a perfect fit and long-term performance. Contact us today to discuss your specific needs and let our experts provide a solution tailored to your goals.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability