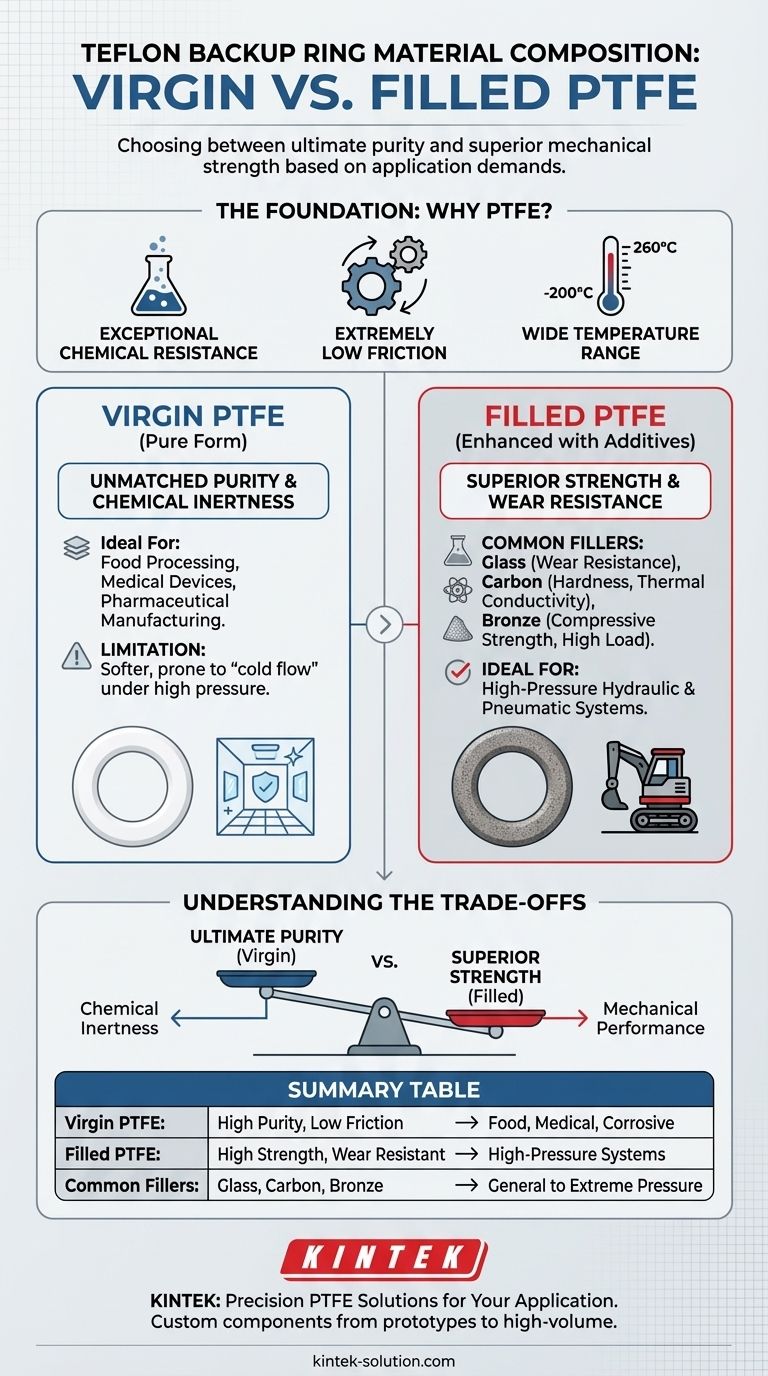

At its core, the material composition of Teflon backup rings varies based on one key distinction: whether the Polytetrafluoroethylene (PTFE) is in its pure form or has been blended with additives. These two categories are known as Virgin PTFE and Filled PTFE. The choice between them is driven entirely by the mechanical and chemical demands of the specific application.

The decision between a pure, virgin PTFE and a mechanically enhanced filled PTFE is a fundamental trade-off. You are essentially choosing between ultimate chemical inertness and superior physical strength.

The Foundation: Why PTFE is the Material of Choice

Before examining the variations, it's crucial to understand why PTFE is the default material for these components. Its inherent properties make it uniquely suited for sealing applications.

Exceptional Chemical Resistance

PTFE is one of the most chemically inert materials known. It resists nearly all industrial chemicals, acids, and solvents, even in highly corrosive or high-temperature environments.

Extremely Low Friction

The material has an exceptionally low coefficient of friction. This self-lubricating, non-stick quality is vital for dynamic applications, reducing wear and ensuring smooth operation.

Wide Temperature Range

PTFE performs reliably across a vast temperature spectrum, typically from -200°C to 260°C (-328°F to 500°F). This allows it to function in environments where many other polymers would fail.

The Two Primary Compositions

The functional differences in Teflon backup rings come from the choice to either use PTFE in its pure state or to enhance it with reinforcing fillers.

Virgin PTFE: The Standard for Purity

This is pure, unadulterated Polytetrafluoroethylene. It contains no additives or fillers.

Its primary advantage is its unmatched chemical resistance and purity. This makes it the only choice for applications where contamination is a critical concern, such as in food processing, medical devices, or pharmaceutical manufacturing.

Filled PTFE: Engineered for Strength

This category involves blending the virgin PTFE base with specific additives to improve its mechanical properties.

These fillers are added to combat PTFE's primary weakness: its tendency to deform or "cold flow" under pressure. Common fillers include:

- Glass: Improves wear resistance and compressive strength.

- Carbon: Increases hardness, load-bearing capability, and thermal conductivity.

- Bronze: Significantly enhances compressive strength and wear resistance, making it ideal for high-pressure hydraulic systems.

Understanding the Trade-offs

Selecting a material is never about finding a "perfect" solution, but about choosing the right set of compromises for your specific problem.

The Limitation of Purity

While chemically superior, virgin PTFE is mechanically softer. In high-pressure applications, it is more susceptible to extrusion into the clearance gap, which is the very problem a backup ring is designed to prevent.

The Compromise of Strength

Adding fillers to create Filled PTFE dramatically improves mechanical strength and wear resistance. However, this enhancement can come at a slight cost.

Fillers can marginally reduce the overall chemical resistance of the compound compared to virgin PTFE. The blend is no longer 100% inert, and the choice of filler must be compatible with the system's media.

Selecting the Right Material for Your Application

Your operational environment and performance goals dictate the correct material choice.

- If your primary focus is chemical purity and non-contamination: Virgin PTFE is the definitive choice for industries like food processing, medical, or pharmaceuticals.

- If your primary focus is high-pressure performance and wear resistance: A Filled PTFE, such as one with carbon or bronze, provides the necessary mechanical strength to prevent extrusion in demanding hydraulic and pneumatic systems.

- If your primary focus is a general-purpose balance of performance and cost: Glass-filled PTFE often provides a good middle ground, enhancing strength and wear resistance effectively.

Ultimately, matching the material composition directly to the application's demands ensures reliability and extends the life of the sealing system.

Summary Table:

| Material Type | Key Characteristics | Ideal For |

|---|---|---|

| Virgin PTFE | Unmatched chemical inertness, high purity, low friction | Food, medical, pharmaceutical, and highly corrosive environments |

| Filled PTFE | Enhanced compressive strength, improved wear resistance | High-pressure hydraulic/pneumatic systems requiring extrusion resistance |

| Common Fillers | Glass: Wear resistance; Carbon: Hardness; Bronze: High load-bearing | General-purpose to extreme-pressure applications |

Need the perfect PTFE backup ring for your specific application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom backup rings for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the ultimate purity of Virgin PTFE or the enhanced strength of a Filled PTFE compound, our precision production and custom fabrication services—from prototypes to high-volume orders—ensure a perfect fit for your system's demands.

Contact our experts today to discuss your requirements and get a solution that delivers reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance