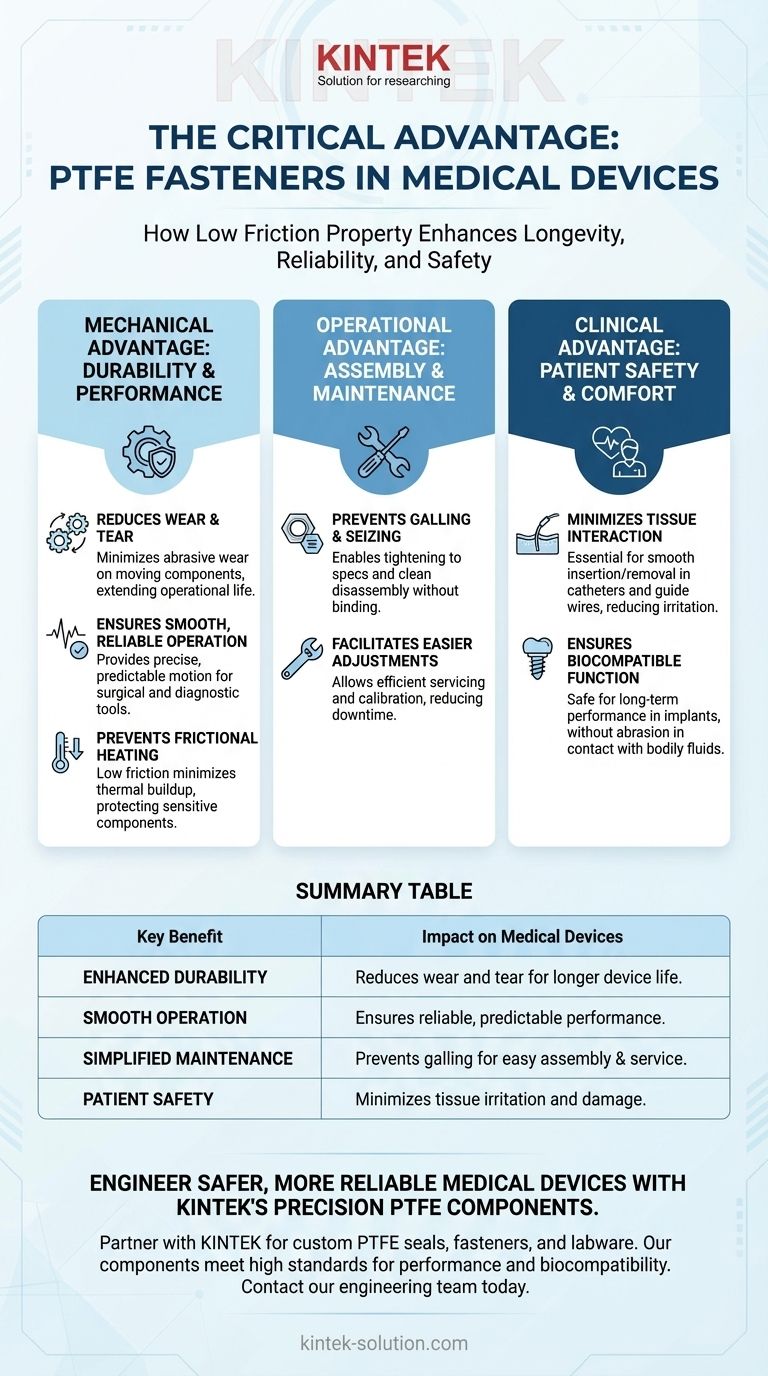

In medical devices, the low friction property of PTFE fasteners is a critical design advantage that directly enhances device longevity, operational reliability, and patient safety. This low coefficient of friction minimizes wear and tear on moving components, ensures smooth and predictable operation, and simplifies both initial assembly and subsequent maintenance.

The core benefit of PTFE's low friction extends beyond simple mechanics. It creates a cascade of advantages, improving a device's durability, making it easier to service, and ultimately reducing risks and discomfort for the patient.

The Mechanical Advantage: Durability and Performance

The primary benefit of a low friction surface is the profound impact it has on the mechanical integrity and function of a medical device over its intended lifespan.

Reducing Wear and Tear

PTFE's exceptionally low coefficient of friction means that parts slide against each other with minimal resistance. This drastically reduces the abrasive wear that can degrade components over time.

For medical devices with moving parts, this translates directly to a longer, more reliable operational life.

Ensuring Smooth, Reliable Operation

The inherent slipperiness of PTFE ensures that mechanisms function smoothly and predictably. This is critical in surgical instruments and diagnostic equipment where precise, repeatable motion is non-negotiable.

This property also reduces the energy required to operate a device, which can be a factor in powered or automated systems.

Preventing Frictional Heating

In dynamic applications with continuous or rapid movement, friction can generate heat. PTFE’s low friction minimizes this thermal buildup.

This protects sensitive electronic components or biological materials within the device from potential heat damage, ensuring greater stability and accuracy.

The Operational Advantage: Assembly and Maintenance

Beyond in-use performance, the low friction of PTFE fasteners provides significant advantages for technicians and engineers who build and service the devices.

Preventing Galling and Seizing

Galling is a form of wear where surfaces adhere and seize, making disassembly difficult or impossible. PTFE’s non-stick, low-friction nature effectively prevents this.

Fasteners can be tightened to precise specifications without binding and can be removed cleanly when needed.

Facilitating Easier Adjustments

This ease of assembly and disassembly is invaluable for devices that require frequent maintenance, calibration, or adjustments throughout their lifecycle.

It allows for more efficient servicing, reducing downtime and operational costs.

The Clinical Advantage: Patient Safety and Comfort

For devices that come into contact with the human body, low friction moves from a mechanical benefit to a critical factor in patient care.

Minimizing Tissue Interaction

In applications like catheters or guide wires, a low-friction surface is essential for smooth insertion and removal. It minimizes irritation and potential damage to sensitive tissues.

PTFE's non-stick quality also proves beneficial in applications like advanced wound dressings, allowing for easy removal without disrupting the healing process.

Ensuring Biocompatible Function

Within the body, such as in implants, PTFE fasteners and components ensure that moving parts function without abrasion.

Combined with its chemical inertness and biocompatibility, the low friction property guarantees safe and reliable long-term performance in contact with bodily fluids and tissues.

Making the Right Choice for Your Application

Selecting a material is about matching its properties to your primary design goal. PTFE's low friction is a powerful tool when applied correctly.

- If your primary focus is device longevity and reliability: PTFE's ability to minimize wear and tear in moving parts is its most significant advantage.

- If your primary focus is ease of maintenance: The way PTFE prevents galling and seizing makes it ideal for devices requiring frequent adjustments or service.

- If your primary focus is patient safety and comfort: The non-stick, low-friction surface is critical for any device that moves against or within human tissue.

Ultimately, leveraging PTFE's low friction is a key strategy for engineering safer, more durable, and more reliable medical devices.

Summary Table:

| Key Benefit | Impact on Medical Devices |

|---|---|

| Enhanced Durability | Reduces wear and tear on moving parts for longer device life. |

| Smooth Operation | Ensures reliable, predictable performance in surgical and diagnostic tools. |

| Simplified Maintenance | Prevents galling and seizing for easy assembly, disassembly, and service. |

| Patient Safety | Minimizes tissue irritation and damage in catheters, implants, and wound care. |

Engineer safer, more reliable medical devices with KINTEK's precision PTFE components.

For over [X] years, KINTEK has partnered with medical device manufacturers to provide custom PTFE seals, fasteners, and labware. Our components are manufactured with the precision and biocompatibility required for critical applications, ensuring your devices meet the highest standards for performance and patient safety.

Whether you need prototypes or high-volume production, our expertise in custom fabrication ensures a perfect fit for your design requirements.

Contact our engineering team today to discuss how our PTFE solutions can enhance your next medical device project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance