On initial purchase, PTFE (Polytetrafluoroethylene) bushes are generally more expensive than traditional bushings made from metal or standard plastics. This higher upfront price is a direct result of the material's advanced properties and manufacturing requirements. However, this initial cost is only a small part of the overall financial picture.

The central decision is not about initial price but about Total Cost of Ownership (TCO). While PTFE has a higher acquisition cost, its self-lubricating nature and extreme durability often result in a significantly lower TCO by eliminating maintenance and extending the service life of the component.

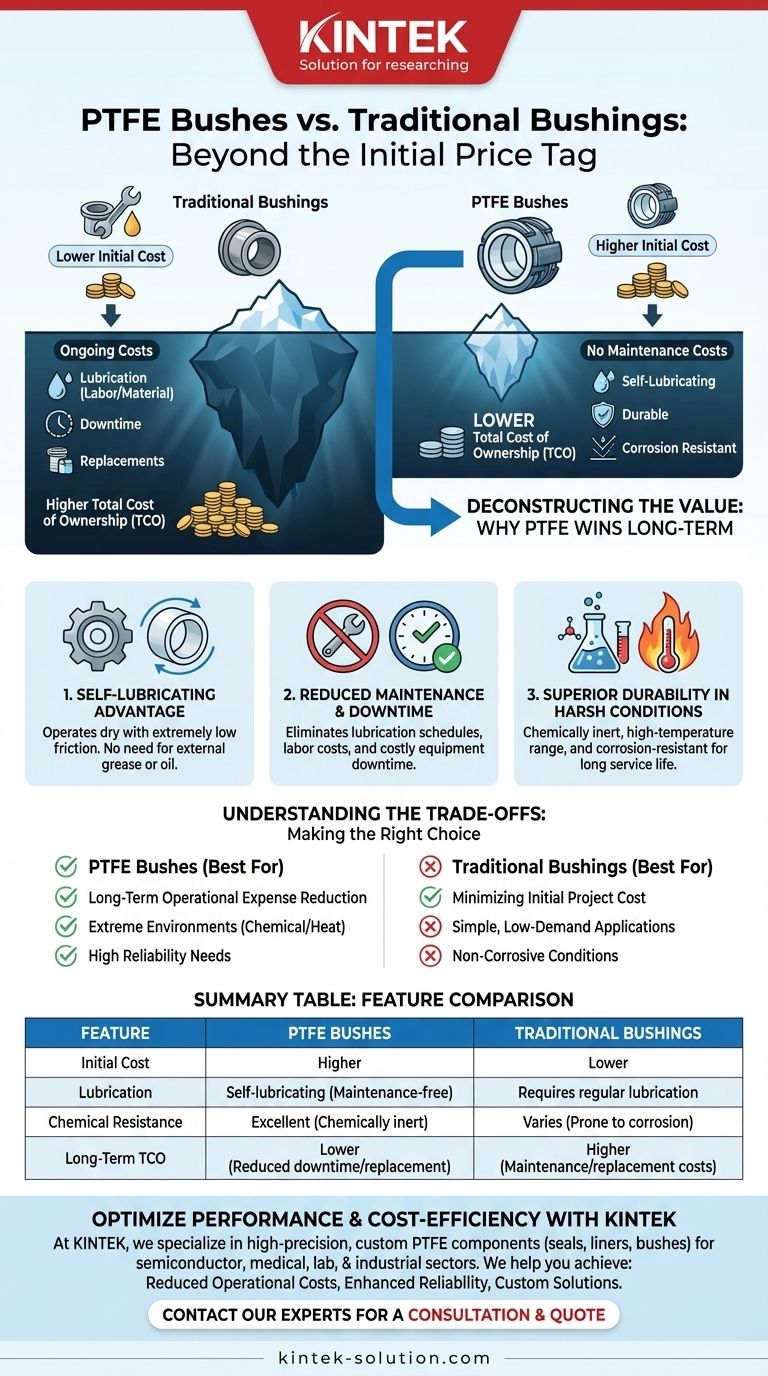

Deconstructing the Value Proposition of PTFE

To understand the cost difference, we must look beyond the price tag and evaluate how each bushing type performs over its entire lifecycle. The unique characteristics of PTFE directly address common failure points and operational costs associated with traditional materials.

The Self-Lubricating Advantage

Traditional metal bushings require external lubrication, such as grease or oil, to reduce friction and prevent wear. This introduces several ongoing costs.

PTFE, by contrast, has an extremely low coefficient of friction and is self-lubricating. It operates dry, providing smooth, efficient movement without any need for additional lubricants.

Reduced Maintenance and Downtime

The need for regular lubrication means traditional bushings demand a maintenance schedule. This involves labor costs for greasing, the cost of the lubricant itself, and often, equipment downtime.

Because PTFE bushes are maintenance-free, they completely eliminate these operational expenses. This is particularly valuable in hard-to-reach locations or in continuous-operation machinery where downtime is extremely costly.

Superior Durability in Harsh Conditions

Traditional bushings have clear operational limits. Metals can corrode when exposed to chemicals or moisture, and standard plastics can degrade in high temperatures.

PTFE is almost entirely chemically inert and has a very high operating temperature range. This resistance to corrosion and heat means PTFE bushes will not fail in environments that would destroy other materials, preventing expensive breakdowns and replacement cycles.

Understanding the Trade-offs

Choosing a bushing is an engineering decision, and there is no single solution that fits every scenario. The higher initial cost of PTFE is not always the right investment.

High-Load Capacity

For applications involving extremely high loads and pressures, certain high-strength metal alloys or bronze bushings may offer superior structural integrity. It is critical to match the bushing's load-carrying capacity to the specific demands of the application.

Cost-Sensitive, Low-Demand Applications

In a simple, easily accessible application with low-intensity use and non-corrosive conditions, a traditional bushing may be sufficient. If minimizing the initial bill of materials is the absolute priority, and regular maintenance is not a significant burden, a cheaper metal or plastic bushing can be the pragmatic choice.

Making the Right Choice for Your Goal

Your final decision should be guided by the long-term strategic goal for your equipment, not just the upfront component cost.

- If your primary focus is minimizing initial project cost: A traditional metal or plastic bushing is often the most economical choice for simple, non-critical applications.

- If your primary focus is reducing long-term operational expenses: PTFE bushes are the superior investment, as their maintenance-free operation and longevity eliminate downstream costs.

- If your primary focus is reliability in extreme environments: PTFE's unparalleled resistance to chemicals, corrosion, and temperature makes it the only dependable option for demanding conditions.

Ultimately, choosing the right bushing requires you to weigh the initial investment against the long-term costs of maintenance, downtime, and replacement.

Summary Table:

| Feature | PTFE Bushes | Traditional Bushings |

|---|---|---|

| Initial Cost | Higher | Lower |

| Lubrication | Self-lubricating (maintenance-free) | Requires regular lubrication |

| Chemical Resistance | Excellent (Chemically inert) | Varies (Prone to corrosion) |

| Long-Term TCO | Lower (Reduced downtime & replacement) | Higher (Maintenance & replacement costs) |

| Ideal For | Harsh environments, high reliability needs | Simple, low-demand, cost-sensitive applications |

Optimize Your Equipment's Performance and Cost-Efficiency

Choosing the right bushing material is critical for the reliability and profitability of your operations. At KINTEK, we specialize in manufacturing high-precision, custom PTFE components—including seals, liners, labware, and bushes—for the semiconductor, medical, laboratory, and industrial sectors.

We help you achieve:

- Reduced Operational Costs: Our maintenance-free PTFE bushes eliminate lubrication schedules and associated downtime.

- Enhanced Reliability: Benefit from superior chemical resistance and durability in extreme environments.

- Custom Solutions: From prototypes to high-volume orders, we fabricate components to your exact specifications.

Let's find the most cost-effective and reliable solution for your specific application.

Contact our experts today for a consultation to discuss your project needs and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications