At its core, Teflon improves the cooking process by creating an exceptionally non-stick surface. This fundamental property prevents food from adhering to the pan, which simplifies the act of cooking delicate items and makes cleanup significantly faster and easier.

The true advantage of Teflon cookware isn't just that it's "slippery." It's a result of the material's unique molecular properties—extremely low friction, chemical inertness, and heat resistance—which work together to prevent food from bonding to the surface.

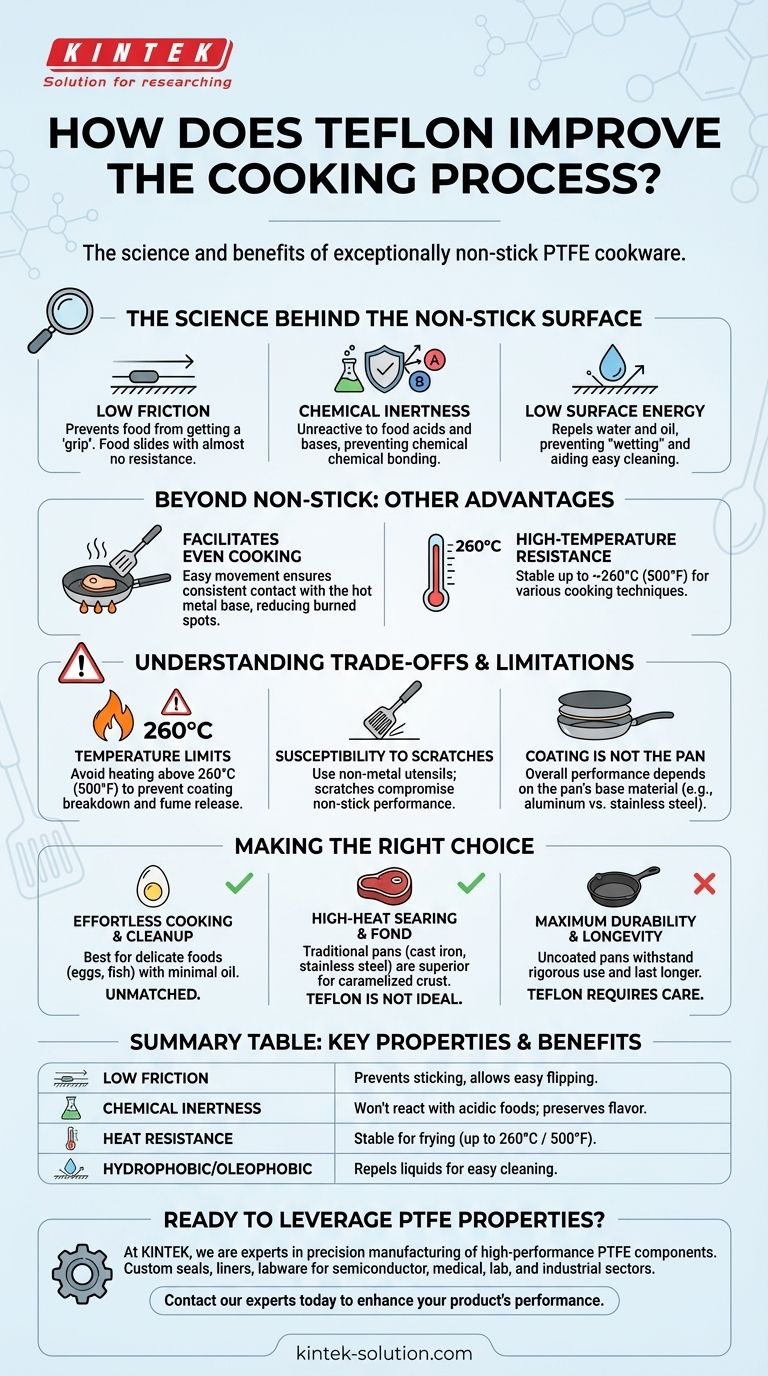

The Science Behind the Non-Stick Surface

To understand why Teflon works so well, we need to look beyond the surface and at the material itself, a polymer known as Polytetrafluoroethylene (PTFE).

Exceptionally Low Friction

Teflon possesses one of the lowest coefficients of friction of any known solid. This means that other materials, including food, slide across its surface with almost no resistance. This property is intrinsic to its molecular structure, preventing food from getting a "grip" on the pan.

Chemical Inertness

The material is highly unreactive. It does not react with the acids or bases commonly found in food, which prevents the chemical bonding that causes sticking in other types of cookware.

Low Surface Energy

Teflon is also hydrophobic and oleophobic, meaning it repels both water and oil. This low surface energy prevents liquids and food residues from "wetting" or spreading across the surface, further contributing to its non-stick performance and easy cleaning.

Beyond Non-Stick: Other Cooking Advantages

While its non-stick nature is the primary benefit, Teflon's other properties also contribute to a better cooking experience.

Facilitating Even Cooking

A common misconception is that Teflon itself improves heat transfer. In reality, PTFE is an insulator. However, in cookware, it is applied as an extremely thin layer over a highly conductive metal like aluminum.

The benefit comes from the non-stick surface allowing food to be moved and flipped easily, ensuring all parts of the food make consistent contact with the hot metal pan. This helps prevent burned or undercooked spots.

High-Temperature Resistance

Teflon is stable and safe for cooking at temperatures up to approximately 260°C (500°F). This resistance allows for a wide range of cooking techniques, from gentle warming to frying and sautéing, without degrading the coating.

Understanding the Trade-offs and Limitations

No material is perfect. To use Teflon effectively and safely, it's critical to understand its limitations.

Temperature Limits are Critical

Heating a Teflon-coated pan above 260°C (500°F) can cause the coating to begin breaking down, releasing polymer fumes. It is crucial to avoid preheating an empty pan or using it for ultra-high-heat techniques like broiling.

Susceptibility to Scratches

The Teflon coating is relatively soft and can be easily damaged by metal utensils, abrasive scouring pads, or stacking. Scratches can compromise the non-stick performance and may cause small particles of the coating to flake off.

The Coating is Not the Pan

The overall cooking performance of a pan—how quickly and evenly it heats—is determined by its base material and construction, not the Teflon coating. A thin aluminum pan with Teflon will perform very differently than a heavy, multi-ply stainless steel pan with the same coating.

Making the Right Choice for Your Goal

Teflon is a specific tool for a specific job. Your cooking style should determine when you use it.

- If your primary focus is effortless cooking and cleanup: Teflon is unmatched for preparing delicate foods like eggs, fish, and pancakes with minimal oil.

- If your primary focus is high-heat searing and developing a fond: A traditional pan, like stainless steel or cast iron, is the superior tool for creating the caramelized crust that builds flavor.

- If your primary focus is maximum durability and longevity: Cookware without a delicate coating, such as cast iron or stainless steel, will generally withstand more rigorous use and last longer.

Understanding these properties allows you to leverage Teflon as the highly effective, specialized tool it is.

Summary Table:

| Property | Benefit in Cooking |

|---|---|

| Low Friction | Prevents food from sticking; allows easy flipping. |

| Chemical Inertness | Won't react with acidic foods; preserves flavor. |

| Heat Resistance | Stable for frying and sautéing (up to 500°F / 260°C). |

| Hydrophobic/Oleophobic | Repels water and oil for exceptionally easy cleaning. |

Ready to leverage the superior properties of PTFE (Teflon) in your products?

At KINTEK, we are experts in precision manufacturing of high-performance PTFE components. Whether you need custom seals, liners, labware, or other specialized parts for the semiconductor, medical, laboratory, or industrial sectors, we deliver the consistent quality and chemical resistance that PTFE is known for.

We specialize in custom fabrication, from prototypes to high-volume orders, ensuring your components meet exact specifications.

Contact our experts today to discuss how our PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials