In the world of high-performance seals, PTFE's chemical resistance is its most defining benefit. This property stems directly from its unique molecular structure, where incredibly strong carbon-fluorine bonds create a material that is chemically inert. This means a PTFE seal will not swell, degrade, or dissolve when exposed to the vast majority of corrosive chemicals, ensuring it maintains its physical integrity and prevents catastrophic leaks.

The core takeaway is that PTFE's chemical resistance is not just a single feature, but the foundation of its reliability. This inertness, combined with its tolerance for extreme temperatures and pressures, makes it the default choice for critical applications where seal failure would lead to equipment damage, safety hazards, or costly downtime.

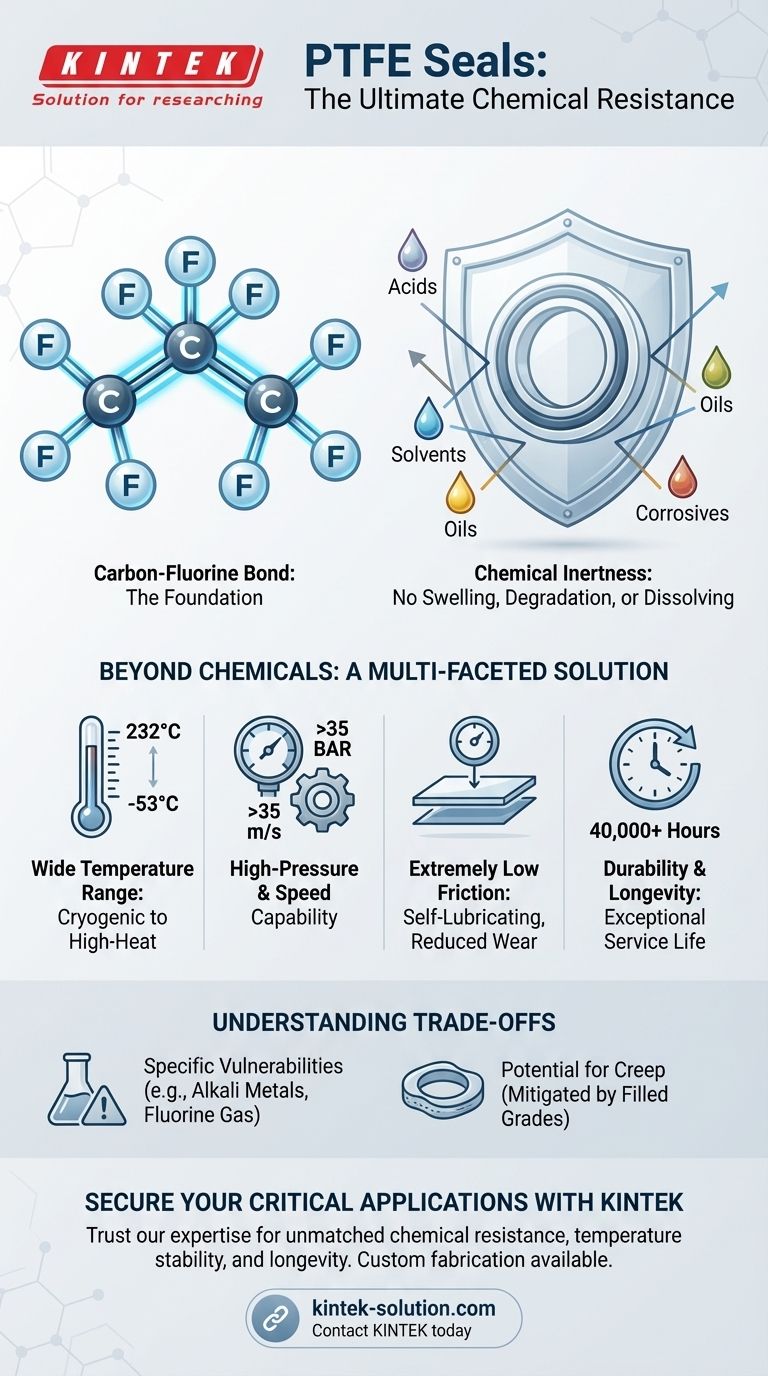

The Foundation of PTFE's Resilience

To understand the benefit of PTFE (Polytetrafluoroethylene), we must first look at its molecular architecture. The material's exceptional properties are not accidental; they are a direct result of its chemistry.

The Carbon-Fluorine Bond

At its core, PTFE consists of a long chain of carbon atoms, each completely shielded by a sheath of fluorine atoms. The bond between carbon and fluorine is one of the strongest known in organic chemistry.

Consequence: Chemical Inertness

This powerful bond makes the polymer molecule exceptionally stable and non-reactive. It lacks "attachment points" for other chemicals to attack, rendering it inert to almost all industrial acids, solvents, oils, and corrosive agents.

Practical Impact on Sealing

For a seal, this chemical inertness is paramount. Unlike conventional elastomers that might swell, soften, or crack when exposed to aggressive media, a PTFE seal maintains its shape, dimensions, and mechanical properties, providing a consistent and reliable sealing force over time.

Beyond Chemicals: A Multi-Faceted Solution

While its chemical resistance is the primary benefit, a seal must perform across several metrics. PTFE's value is amplified by its strong performance in other critical areas, making it a comprehensive solution for demanding environments.

Wide Temperature Range

PTFE seals operate effectively across an exceptionally broad temperature spectrum, typically from -53°C to 232°C (-63°F to 450°F). This allows them to function in applications ranging from cryogenic systems to high-heat industrial processes without becoming brittle or degrading.

High-Pressure and High-Speed Capability

These seals are engineered to handle significant operational stresses. They can maintain a tight seal at pressures exceeding 35 BAR (500 PSI) and are suitable for high-speed rotary applications with surface speeds over 35 m/s.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This property, often referred to as being "self-lubricating," reduces wear and tear on both the seal and equipment shafts, lowers operational energy requirements, and allows for effective sealing even in dry or abrasive media.

Durability and Longevity

The combination of chemical inertness and physical robustness gives PTFE seals an exceptional service life. They have a virtually unlimited shelf life and can achieve over 40,000 hours of maintenance-free service in certain applications, drastically reducing operating costs.

Understanding the Trade-offs and Limitations

No material is universally perfect. Acknowledging PTFE's limitations is crucial for making an informed engineering decision and avoiding misapplication.

Specific Chemical Vulnerabilities

While resistant to most chemicals, PTFE is not compatible with a few specific substances. These include molten or dissolved alkali metals (like sodium), fluorine gas, and other extremely potent oxidizing agents. Exposure to these will cause the material to degrade.

Potential for Creep and Cold Flow

Standard PTFE can be susceptible to "creep" or "cold flow," where the material slowly deforms under sustained pressure. This is often mitigated by using filled grades of PTFE, where materials like glass, carbon, or bronze are added to enhance creep resistance and mechanical strength.

Total Cost of Ownership

PTFE seals often represent a higher initial component cost compared to standard elastomer seals. However, this is frequently offset by their vastly longer service life, reduced maintenance frequency, and the prevention of costly failures, leading to a lower total cost of ownership.

Making the Right Choice for Your Application

Selecting the correct seal material requires aligning the material's properties with the operational demands of the system.

- If your primary focus is reliability in aggressive media: PTFE is the benchmark material for chemical processing, pharmaceutical, and semiconductor applications where seal integrity is non-negotiable.

- If your primary focus is high-performance mechanical systems: The combination of low friction, high-speed capability, and wide temperature range makes PTFE ideal for demanding aerospace, automotive, and industrial machinery.

- If your primary focus is a standard, low-stress environment: For applications without extreme temperatures or corrosive chemicals, a more conventional and cost-effective elastomer seal may be a more suitable choice.

Ultimately, choosing a PTFE seal is an investment in the long-term stability and reliability of your equipment.

Summary Table:

| Key Property | Benefit for Seals | Typical Performance Range |

|---|---|---|

| Chemical Inertness | Resists swelling, degradation from acids, solvents, oils | Inert to most industrial chemicals |

| Temperature Range | Maintains integrity from cryogenic to high-heat processes | -53°C to 232°C (-63°F to 450°F) |

| Pressure & Speed | Handles extreme operational stresses | >35 BAR (500 PSI), >35 m/s surface speed |

| Low Friction | Reduces wear, lowers energy requirements, self-lubricating | One of the lowest coefficients of friction |

| Service Life | Long-term reliability with minimal maintenance | Up to 40,000+ hours in certain applications |

Secure Your Critical Applications with KINTEK's Precision PTFE Seals

When seal failure is not an option, trust KINTEK's expertise in manufacturing high-performance PTFE components. Our seals deliver unmatched chemical resistance, temperature stability, and longevity—preventing costly downtime and safety hazards in semiconductor, medical, laboratory, and industrial settings.

We offer custom fabrication from prototypes to high-volume orders, ensuring perfect compatibility with your specific operational demands.

Contact KINTEK today to discuss your sealing requirements and receive a tailored solution that enhances your equipment's reliability and reduces total cost of ownership.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What materials can PTFE balls be made from? Virgin, Modified, or Filled Compounds for Specific Performance

- What makes PTFE bushes suitable for high-temperature applications? Unlock Reliability in Extreme Heat

- How does surface finish impact PTFE sheet performance? A Guide to Optimizing for Your Application

- What are the common challenges in machining intricate PTFE components? Overcome Material Instability & Burrs

- What microstructure does expanded PTFE sheet have? Unlock Superior Sealing & Insulation

- What material is used to make PTFE bushings? The Ultimate Guide to PTFE's Performance

- What are the main advantages of PTFE processing machines? Achieve Superior Component Performance

- How is Teflon parts machining adapting to sustainability goals? Maximize Lifespan & Minimize Waste