In short, PTFE exhibits exceptional performance with nearly all common industrial oils and fuels. Its inherent chemical inertness makes it one of the most reliable and widely used materials for applications involving hydraulic oils, diesel, kerosene, motor oils, lubricants, and other petroleum-based products.

The core reason for PTFE's outstanding compatibility is its molecular structure. The powerful carbon-fluorine bonds create a chemically inert surface that is virtually immune to attack from the hydrocarbons found in oils and fuels.

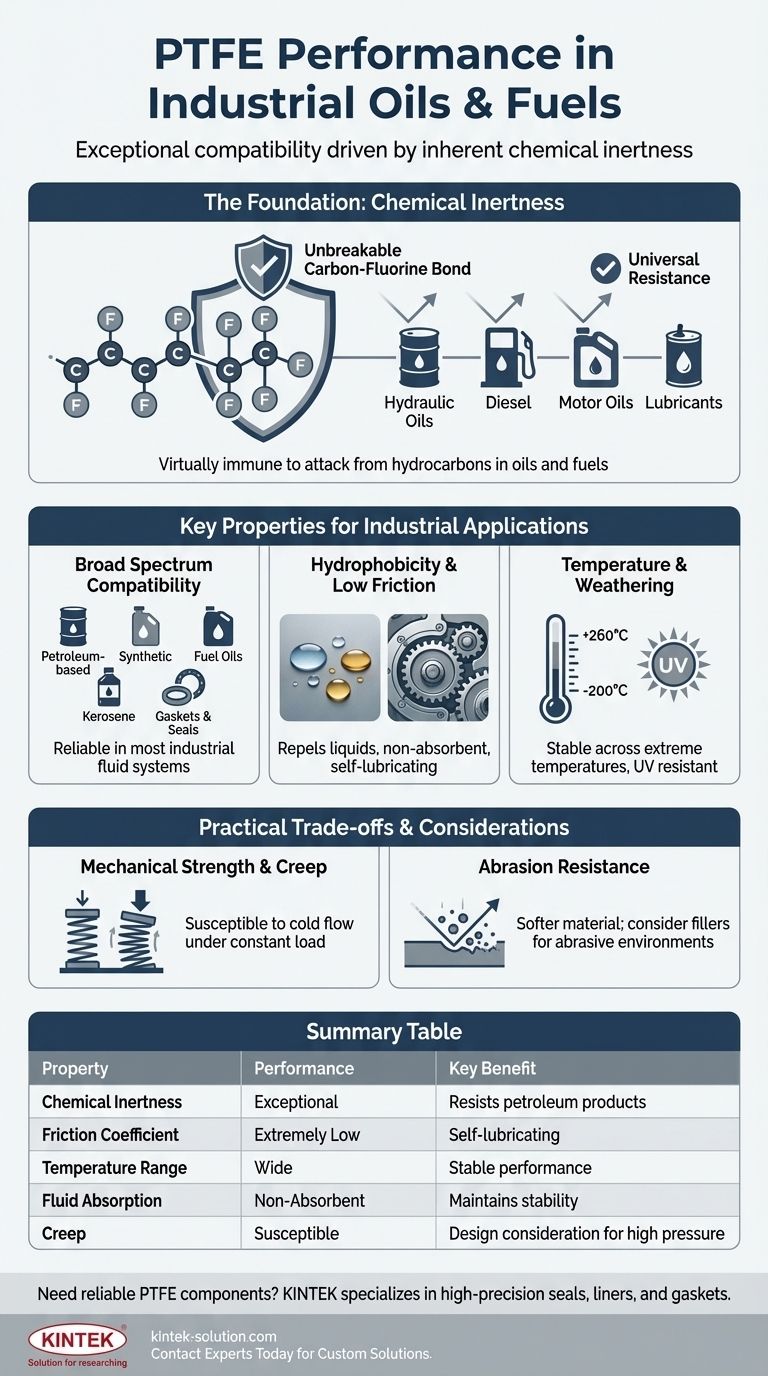

The Foundation of PTFE's Resistance: Chemical Inertness

Polytetrafluoroethylene (PTFE) is fundamentally non-reactive. This quality is not an additive or a coating; it is an intrinsic property of the material itself, making its performance predictable and highly reliable in harsh chemical environments.

The Unbreakable Carbon-Fluorine Bond

At a molecular level, PTFE consists of a long chain of carbon atoms completely shielded by fluorine atoms. The carbon-fluorine (C-F) bond is one of the strongest single bonds in organic chemistry.

This powerful bond structure makes PTFE almost universally resistant to chemical attack. It effectively resists nearly all acids, bases, and organic solvents, including the complex hydrocarbon chains that constitute oils and fuels.

Broad Spectrum Compatibility

PTFE's chemical resistance translates to excellent performance with a wide array of industrial fluids.

This includes both petroleum-based and synthetic hydraulic oils, as well as diesel fuel, fuel oils, motor oil, kerosene, and various lubricants. It is a go-to material for seals, gaskets, and linings in fuel and oil systems.

Repelling Liquids (Hydrophobicity)

PTFE is also hydrophobic, meaning it repels water and, by extension, does not readily absorb oils.

This property prevents fluids from soaking into the material, which is critical for maintaining dimensional stability and integrity. It also makes PTFE an excellent barrier material for preventing leaks.

Key Properties for Industrial Applications

Beyond simple chemical compatibility, several other characteristics of PTFE make it ideal for use with oils and fuels, particularly in mechanical and industrial settings.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This self-lubricating property is invaluable in dynamic applications like seals or bearings where parts move against each other.

Softness and Formability

PTFE is a relatively soft and formable material. This allows it to conform to irregular surfaces, creating a highly effective seal.

For example, expanded PTFE is often used for gasketing on chemical pipe flanges in the oil and gas industry to ensure a tight, leak-proof connection.

Temperature and Weathering Resistance

Industrial systems often operate at elevated temperatures and are exposed to the elements. PTFE performs well across a wide temperature range and has excellent resistance to weathering and UV degradation, ensuring long-term stability.

Understanding the Practical Trade-offs

While PTFE's chemical performance is nearly unmatched, its mechanical properties present important trade-offs that must be considered during material selection and component design.

Mechanical Strength and Creep

PTFE is not a high-strength structural plastic. As a soft material, it can be susceptible to "creep" or cold flow, where it slowly deforms over time under a constant load. This is a critical consideration for high-pressure seals or load-bearing components.

Abrasion Resistance

The same softness that makes PTFE an excellent sealing material also makes it less resistant to abrasion than harder plastics. In environments with abrasive particles, virgin PTFE may wear more quickly. Fillers like glass or carbon can be added to improve its wear resistance.

Making the Right Choice for Your Application

Selecting PTFE is often an excellent decision, but its suitability depends on the specific demands of the system.

- If your primary focus is static sealing (gaskets, O-rings): PTFE is an ideal choice due to its unmatched chemical inertness and ability to conform to surfaces.

- If your primary focus is a dynamic or high-pressure application: PTFE's low friction is a major benefit, but you must account for its softness and potential for creep in your design.

- If your primary focus is environmental exposure and fluid transport: PTFE's resistance to weathering, temperature, and chemical attack makes it a superior material for hoses and linings.

Ultimately, PTFE's chemical immunity makes it a foundational material for safely and reliably handling nearly any industrial oil or fuel.

Summary Table:

| Property | Performance with Oils & Fuels | Key Benefit for Industry |

|---|---|---|

| Chemical Inertness | Exceptional | Resists virtually all petroleum-based products |

| Friction Coefficient | Extremely Low | Self-lubricating for dynamic seals and bearings |

| Temperature Range | Wide | Stable performance from cryogenic to high temperatures |

| Fluid Absorption | Non-Absorbent (Hydrophobic) | Maintains dimensional stability and prevents leaks |

| Trade-off: Creep | Susceptible under constant load | Requires design consideration for high-pressure seals |

Need reliable PTFE components for your oil, fuel, or chemical systems?

KINTEK specializes in manufacturing high-precision PTFE seals, liners, gaskets, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get components that deliver unmatched chemical resistance and performance in your specific application.

Contact our experts today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance