In short, Polytetrafluoroethylene (PTFE) exhibits exceptional resistance to all common types of water. Its performance is unaffected by whether the water is distilled, soft, or hard. This resilience holds true across a wide operational temperature range, including up to the boiling point of water at 100°C (212°F).

The specific composition of the water—whether it contains dissolved minerals or is highly purified—is irrelevant to PTFE. The material's fundamental chemical inertness makes it virtually immune to any form of water-based corrosion or degradation.

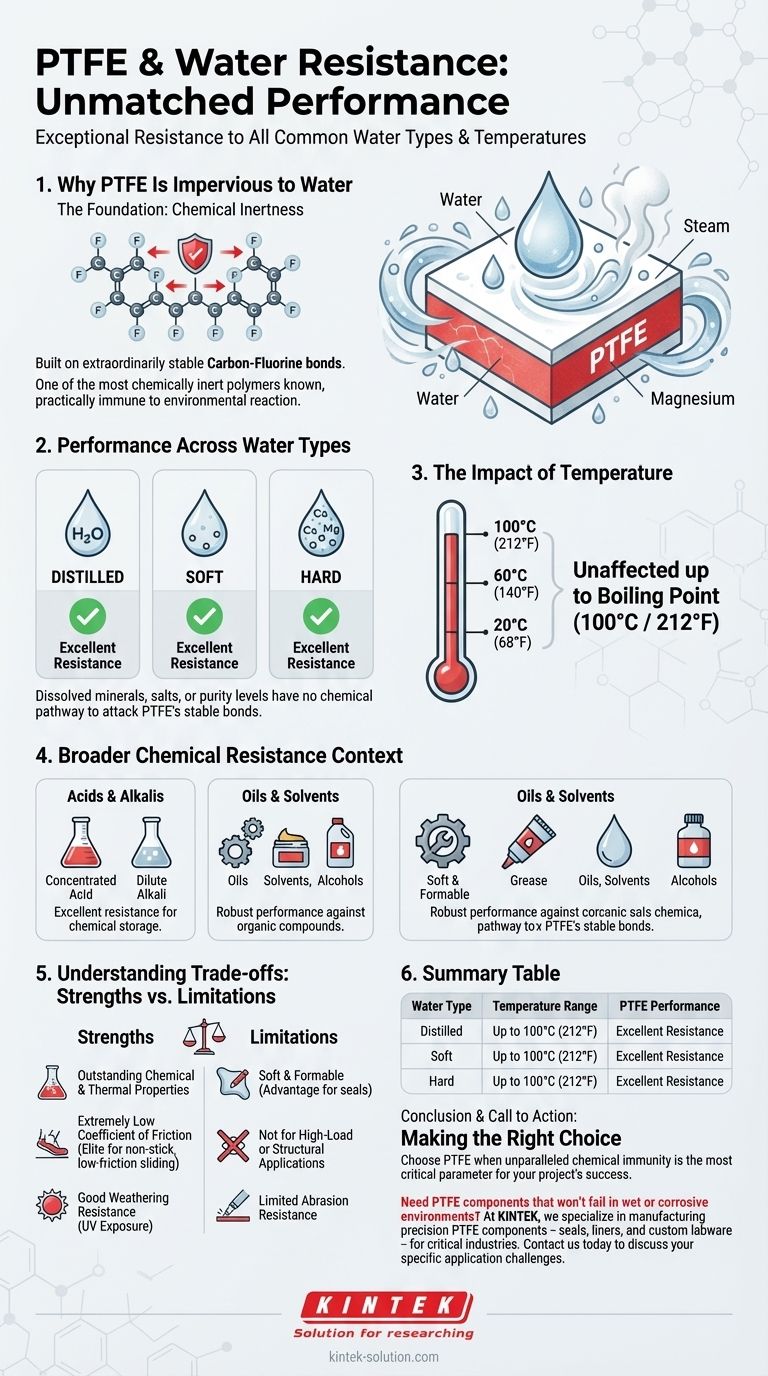

Why PTFE Is Impervious to Water

The exceptional performance of PTFE in aqueous environments is not a feature unique to water but rather a small subset of its overall chemical immunity. Understanding this principle is key to using the material effectively.

The Foundation: Chemical Inertness

The reliability of PTFE stems from its molecular structure, which is built on powerful carbon-fluorine bonds. These bonds are extraordinarily stable and non-reactive.

This structure makes PTFE one of the most chemically inert polymers known. It does not react with its environment, which is why it's a benchmark material for use in highly corrosive or sensitive applications.

Performance Across Water Types

PTFE is documented as being fully resistant to distilled, soft, and hard water.

The dissolved minerals and salts that define hard water have no chemical pathway to attack PTFE's stable bonds. Likewise, the slightly higher reactivity of purified or distilled water has no effect.

The Impact of Temperature

This chemical resistance is maintained at elevated temperatures. The references confirm that PTFE's performance in water is unchanged at temperatures of 20°C (68°F), 60°C (140°F), and 100°C (212°F).

A Broader Perspective on Chemical Resistance

To fully appreciate PTFE's stability in water, it's useful to see it in the context of its resistance to far more aggressive substances.

Resistance to Acids and Alkalis

PTFE shows excellent resistance to both concentrated and dilute acids and alkalis. This is why it is frequently used to make bottles and linings for storing highly reactive chemicals.

Performance with Oils and Solvents

The material is also resistant to a vast range of organic compounds, including oils, greases, hydrocarbons, ketones, and alcohols. Its performance against these substances is just as robust as it is against water.

Understanding the Trade-offs

While its chemical and thermal properties are outstanding, PTFE is not the solution for every engineering problem. Its limitations are primarily mechanical.

Mechanical Properties

PTFE is a relatively soft and formable material. While this is an advantage for creating seals and form-in-place gaskets, it means the material is not suitable for high-load or structural applications.

Its primary mechanical strength is its extremely low coefficient of friction, making it an elite choice for non-stick surfaces and low-friction sliding parts, but not for components requiring high rigidity or abrasion resistance.

Weathering and Environment

PTFE possesses good weathering resistance, meaning it holds up well to UV exposure and outdoor conditions, further enhancing its reliability in applications where environmental exposure is a factor.

Making the Right Choice for Your Application

Selecting a material requires balancing its strengths against the demands of the specific task.

- If your primary focus is pure chemical containment: PTFE is an ideal choice, as its inertness ensures no degradation or leaching when in contact with any type of water or most chemical agents.

- If your primary focus is a high-load mechanical component: You should evaluate more rigid polymers or metals, as PTFE's softness will not provide the necessary structural integrity or abrasion resistance.

- If your primary focus is a low-friction seal or lining in a wet environment: PTFE is an excellent candidate, combining elite chemical resistance with one of the lowest friction surfaces available.

Ultimately, you should choose PTFE when its unparalleled chemical immunity is the most critical parameter for your project's success.

Summary Table:

| Water Type | Temperature | PTFE Performance |

|---|---|---|

| Distilled | Up to 100°C (212°F) | Excellent Resistance |

| Soft | Up to 100°C (212°F) | Excellent Resistance |

| Hard | Up to 100°C (212°F) | Excellent Resistance |

Need PTFE components that won't fail in wet or corrosive environments?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for industries where chemical resistance is non-negotiable. Whether you're in semiconductor manufacturing, medical technology, or laboratory research, our custom fabrication services ensure your parts perform reliably from prototype to high-volume production.

Contact us today to discuss how our PTFE solutions can solve your specific application challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance