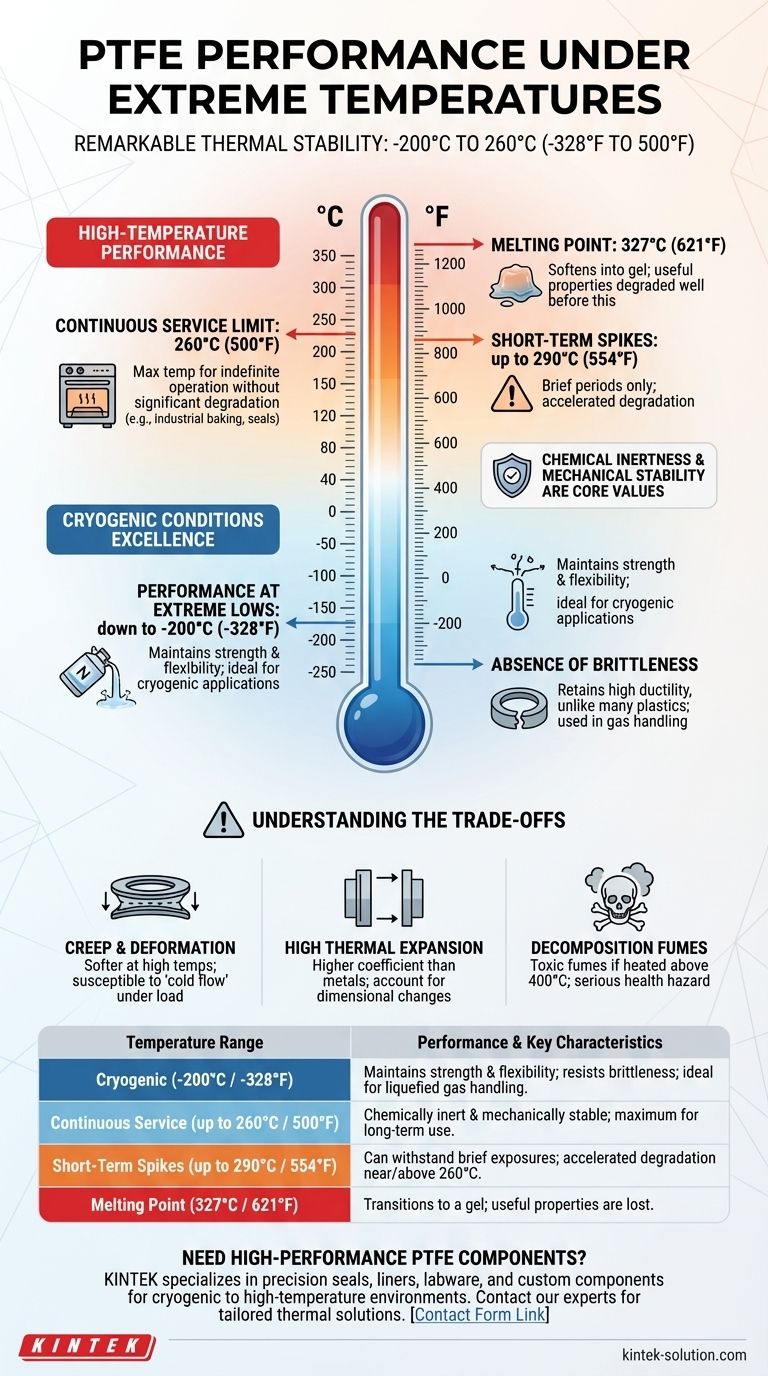

Polytetrafluoroethylene (PTFE) exhibits remarkable thermal stability, making it one of the most versatile high-performance polymers for extreme temperature applications. It reliably operates over an exceptionally broad range, maintaining its critical properties from cryogenic lows of approximately -200°C (-328°F) up to a continuous service temperature of 260°C (500°F). While its actual melting point is higher, this operational range defines where it performs without significant degradation.

The core value of PTFE is not just its ability to survive extreme temperatures, but its capacity to remain chemically inert and mechanically stable across this vast thermal spectrum, a quality that most other materials lack.

Understanding High-Temperature Performance

PTFE's molecular structure—a strong carbon-fluorine bond—is the source of its exceptional thermal resistance. This stability allows it to function in environments where many other polymers would decompose or fail.

The Continuous Service Limit

The most critical figure for engineers is the continuous service temperature of 260°C (500°F). This is the maximum temperature at which PTFE can operate indefinitely without a significant loss of its mechanical properties. Applications include industrial baking processes, high-temperature seals, and insulation for heating elements.

Short-Term Temperature Spikes

For brief periods, PTFE can withstand even higher temperatures. Some data suggests it can handle short-term exposure up to 290°C (554°F). However, operating near or above its continuous limit for extended periods will accelerate material degradation.

The Melting Point Distinction

It is essential to distinguish the service temperature from the melting point, which is 327°C (621°F). PTFE does not truly melt into a liquid but rather softens into a gel-like substance. Its useful properties begin to degrade significantly well before it reaches this point.

Excelling in Cryogenic Conditions

PTFE's performance at extremely low temperatures is just as impressive as its heat resistance. It is a preferred material for cryogenic applications where other materials would become dangerously brittle.

Performance at Extreme Lows

PTFE maintains good strength and flexibility down to -200°C (-328°F). Some sources indicate usability in even more extreme conditions, approaching as low as -270°C (-454°F), which is near absolute zero.

The Absence of Brittleness

Unlike many plastics and elastomers that fracture easily when frozen, PTFE retains a high degree of ductility. This allows it to be used for seals, gaskets, and components in equipment handling liquefied gases like nitrogen and helium.

Understanding the Trade-offs

No material is perfect, and leveraging PTFE effectively requires understanding its limitations, especially when temperature is a factor.

Creep and Deformation Under Load

As PTFE approaches its upper service temperature, it becomes softer. If subjected to a constant mechanical load (like a compressed gasket), it will be more susceptible to "creep" or "cold flow," a slow, permanent deformation over time.

High Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion compared to metals. In designs with tight tolerances that experience wide temperature swings, this expansion and contraction must be accounted for to prevent part failure or loss of sealing pressure.

Decomposition Fumes

While stable up to 260°C, if heated to significantly higher temperatures (above 400°C), PTFE will decompose. The fumes produced during decomposition are toxic and pose a serious health hazard, a critical safety consideration for any design.

Making the Right Choice for Your Goal

Selecting a material requires balancing its capabilities with the specific demands of your application.

- If your primary focus is high-heat industrial processes: Rely on the 260°C continuous limit but be sure to manage mechanical loads to mitigate the risk of material creep.

- If your primary focus is cryogenic applications: Leverage PTFE’s exceptional ductility at temperatures down to -200°C, where most other polymers would become brittle and fail.

- If your primary focus is components with tight tolerances: Account for PTFE's high rate of thermal expansion in your design to ensure dimensional stability across your expected temperature range.

By understanding both its exceptional range and its practical limitations, you can confidently specify PTFE for the most demanding thermal environments.

Summary Table:

| Temperature Range | Performance & Key Characteristics |

|---|---|

| Cryogenic (-200°C / -328°F) | Maintains strength & flexibility; resists brittleness; ideal for liquefied gas handling. |

| Continuous Service (up to 260°C / 500°F) | Chemically inert & mechanically stable; maximum for long-term use without significant degradation. |

| Short-Term Spikes (up to 290°C / 554°F) | Can withstand brief exposures, but accelerated degradation occurs near/above 260°C. |

| Melting Point (327°C / 621°F) | Transitions to a gel; useful properties are lost well before this point. |

Need high-performance PTFE components for extreme temperatures?

KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components that excel in the most demanding thermal environments, from cryogenic applications in the medical and laboratory sectors to high-temperature processes in the semiconductor and industrial fields.

We combine expert material knowledge with custom fabrication capabilities—from prototypes to high-volume orders—to ensure your components perform reliably and safely.

Contact our experts today to discuss your specific requirements and get a solution tailored to your thermal challenges.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is Teflon and what is its chemical name? Unpacking the Science of PTFE

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity

- How does PTFE react to common solvents? Discover Its Near-Total Chemical Immunity

- When was PTFE discovered and developed? The Accidental Invention That Changed Industries

- What is Teflon and what are its alternative names? Understanding PTFE, the Material Behind the Brand