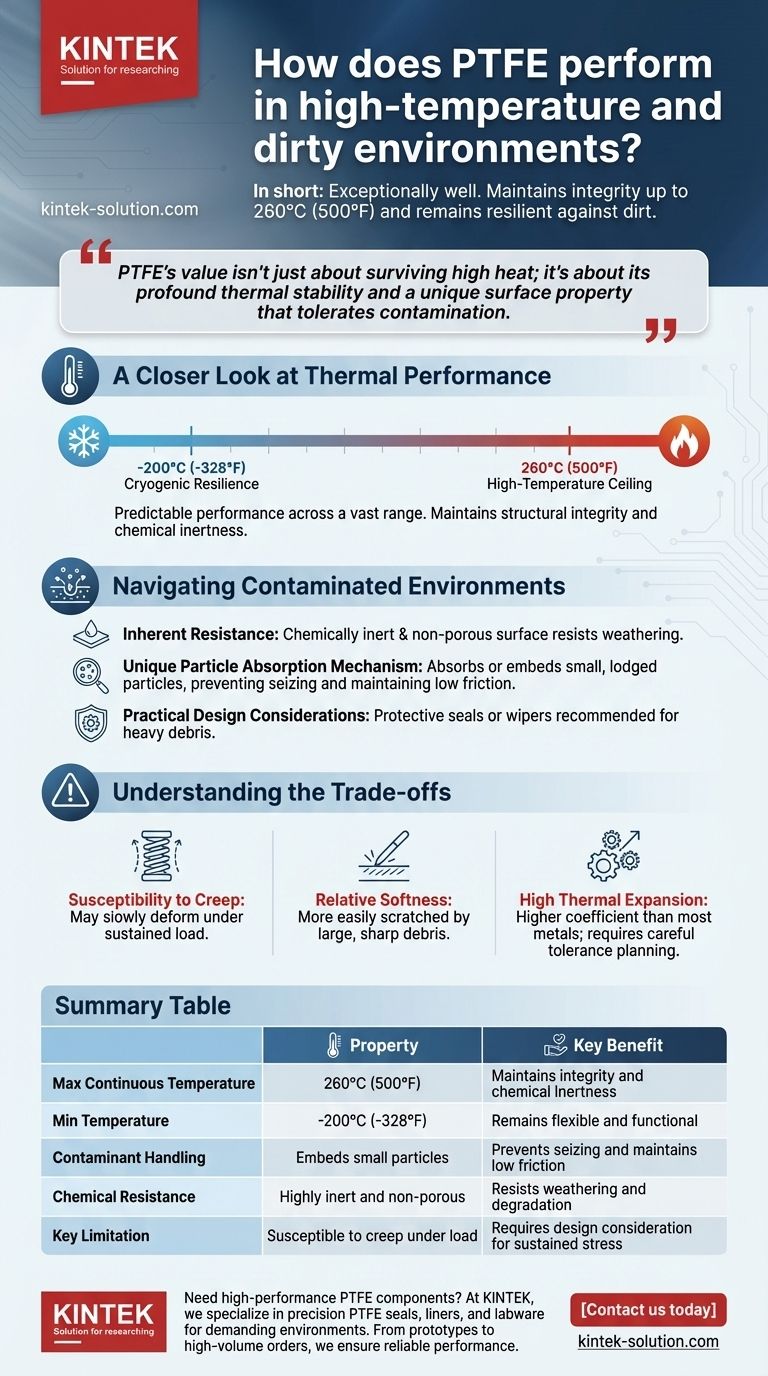

In short, Polytetrafluoroethylene (PTFE) performs exceptionally well in both high-temperature and contaminated environments. It maintains its integrity and core properties at continuous service temperatures up to 260°C (500°F), and its unique surface characteristics make it remarkably resilient against dirt and small particulates.

PTFE's value in harsh conditions isn't just about surviving high heat; it's about its profound thermal stability and a unique surface property that tolerates contamination. This combination ensures consistent, low-friction performance where other materials would quickly degrade or seize.

A Closer Look at Thermal Performance

PTFE is defined by its ability to function reliably across an incredibly wide temperature spectrum. This stability is one of its most critical engineering advantages.

The High-Temperature Ceiling

PTFE has a continuous service temperature of up to 260°C (500°F). Unlike many plastics that melt or degrade, PTFE maintains its structural integrity and chemical inertness at these elevated temperatures, making it ideal for industrial, aerospace, and medical applications.

This high thermal resistance ensures that components like O-rings, seals, and bushings will not burn or fail in environments that would destroy lesser materials.

Resilience in Cryogenic Conditions

Equally impressive is PTFE's performance at the other end of the scale. It remains functional and avoids becoming brittle at temperatures as low as -200°C (-328°F).

This makes it a rare material that is equally suited for both high-temperature industrial processes and cryogenic applications where extreme cold is a constant.

The Benefit of Thermal Stability

The key takeaway is PTFE's predictable performance across this vast temperature range. Its properties do not change drastically with temperature swings, ensuring reliability whether in the vacuum of space, a high-pressure medical device, or a hot industrial machine.

Navigating Contaminated Environments

While no material is immune to its surroundings, PTFE possesses unique qualities that allow it to operate effectively in environments with dust, dirt, and other particulates.

Inherent Resistance to Contaminants

PTFE is highly resistant to weathering and environmental contaminants. Its chemically inert and non-porous surface does not readily degrade when exposed to harsh conditions, giving it a very long operational and shelf life.

A Unique Particle Absorption Mechanism

A critical feature of PTFE is its ability to absorb or embed small, lodged particles. Instead of a hard foreign particle scoring a mating surface or causing movement to seize, the softer PTFE surface can envelop it.

This "self-healing" characteristic prevents minor contamination from causing catastrophic failure in a moving system, maintaining the low-friction surface.

Practical Design Considerations

While PTFE is resilient, best practices still apply in heavily contaminated areas. For instance, designing a protective seal or wiper around a PTFE component is a sensible engineering step to prevent the accumulation of large-scale debris.

Understanding the Trade-offs

To use PTFE effectively, it is critical to understand its limitations. Its strengths in some areas create relative weaknesses in others that must be accounted for in design.

Susceptibility to Creep

Under a sustained load, especially at elevated temperatures, PTFE can be subject to "creep" or cold flow. This means it may slowly deform over time, a factor that must be considered in high-load structural applications.

Relative Softness

PTFE is a relatively soft material. While this allows it to embed small particles, it also means it can be more easily scratched or damaged by large, sharp debris compared to a hard metal or ceramic.

High Thermal Expansion

PTFE has a higher coefficient of thermal expansion than most metals. Engineers must account for this in assemblies that will experience wide temperature swings to avoid issues with tolerance, fit, and potential stress.

Making the Right Choice for Your Application

Selecting a material requires aligning its properties with your primary engineering goal. PTFE offers a distinct set of advantages for demanding conditions.

- If your primary focus is extreme temperature stability: PTFE's reliable performance across its vast operating range, from -200°C to 260°C, is its defining feature.

- If your primary focus is reliability in dusty or dirty mechanical systems: PTFE's unique ability to embed small particles without seizing makes it an excellent choice for low-friction, maintenance-free components.

- If your primary focus is long-term durability in exposed conditions: PTFE's inherent resistance to weathering and environmental degradation ensures a long and predictable service life.

Ultimately, leveraging PTFE effectively means designing systems that capitalize on its unique resilience while respecting its physical limitations.

Summary Table:

| Property | Performance | Key Benefit |

|---|---|---|

| Max Continuous Temperature | 260°C (500°F) | Maintains integrity and chemical inertness |

| Min Temperature | -200°C (-328°F) | Remains flexible and functional |

| Contaminant Handling | Embeds small particles | Prevents seizing and maintains low friction |

| Chemical Resistance | Highly inert and non-porous | Resists weathering and degradation |

| Key Limitation | Susceptible to creep under load | Requires design consideration for sustained stress |

Need high-performance PTFE components for your demanding environment?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, and labware that thrive in extreme conditions. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom fabrication—from prototypes to high-volume orders—ensures your components deliver reliable, low-friction performance where it matters most.

Contact us today to discuss how our PTFE solutions can enhance your application's durability and efficiency!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications