In a direct comparison, Polycarbonate (PC) offers vastly superior impact resistance, while Polytetrafluoroethylene (PTFE) provides significantly better thermal properties. PC is known for its exceptional toughness and is often used for protective gear, whereas PTFE is prized for its ability to withstand extreme temperatures and harsh chemicals.

The choice between Polycarbonate and PTFE is a fundamental trade-off between mechanical strength and environmental stability. You select PC for its toughness and structural integrity, while you choose PTFE for its unmatched performance in high-temperature and chemically aggressive environments.

The Core Performance Divide: Strength vs. Stability

These two polymers occupy very different ends of the performance spectrum. Understanding their core strengths is the first step in proper material selection.

Polycarbonate (PC): The Benchmark for Toughness

Polycarbonate is an amorphous thermoplastic renowned for its incredible impact strength. It is the material of choice for applications where durability and resistance to fracture are paramount.

Think of safety glasses, riot shields, and machine guards. PC’s ability to absorb energy without shattering makes it a go-to material for protecting people and equipment from physical impact.

PTFE: The Champion of Extreme Environments

PTFE, a semi-crystalline polymer, is defined by its remarkable stability. It has a very high melting point of 327°C (621°F) and maintains its properties across a vast temperature range.

Its true strength lies in its chemical inertness and low friction. PTFE is resistant to nearly all acids, solvents, and bases, making it essential for seals, gaskets, and linings in the chemical processing industry.

Key Differentiating Properties

The differences in impact and thermal resistance stem from the fundamental nature of each material. These differences extend to other critical properties as well.

Thermal Performance

PTFE is the clear winner for high-temperature applications. Its high melting point and excellent thermal stability far exceed that of PC, which begins to soften and deform at much lower temperatures.

Coefficient of Friction

PTFE is one of the most slippery materials known, with a coefficient of friction around 0.04. This is why it's used for non-stick coatings and low-wear bearings.

Polycarbonate, by contrast, has a much higher coefficient of friction and is not suitable for low-friction applications without modification or lubrication.

Chemical Resistance

Here again, PTFE has a significant advantage. Its molecular structure makes it almost completely inert.

Polycarbonate is susceptible to degradation from certain solvents, oils, and cleaning agents, which can cause crazing or cracking over time.

Understanding the Trade-offs

Neither material is perfect for every situation. Choosing one means accepting the inherent limitations of the other.

The Weakness of Polycarbonate

While incredibly tough, PC is not as resilient to environmental factors. It can be scratched easily without a hard coat and is vulnerable to UV degradation, which can cause it to yellow and become brittle over time. Its chemical resistance is also limited.

The Weakness of PTFE

PTFE's exceptional stability comes at the cost of mechanical strength. It is a relatively soft material with low tensile strength and poor abrasion resistance. It is also susceptible to "creep," meaning it can deform permanently when held under a constant load.

Making the Right Choice for Your Application

Your final decision should be dictated entirely by the primary demands of your project.

- If your primary focus is impact resistance and structural integrity: Choose Polycarbonate for its exceptional toughness and rigidity, ideal for housings, protective shields, and structural components.

- If your primary focus is high-temperature performance: Choose PTFE, as it maintains its properties at temperatures that would cause PC to fail completely.

- If your primary focus is chemical resistance or low friction: Choose PTFE for its near-total chemical inertness and exceptionally slippery surface, perfect for seals, liners, and bearings.

Ultimately, selecting the right material depends on a clear understanding of whether your application needs to survive physical force or a harsh environment.

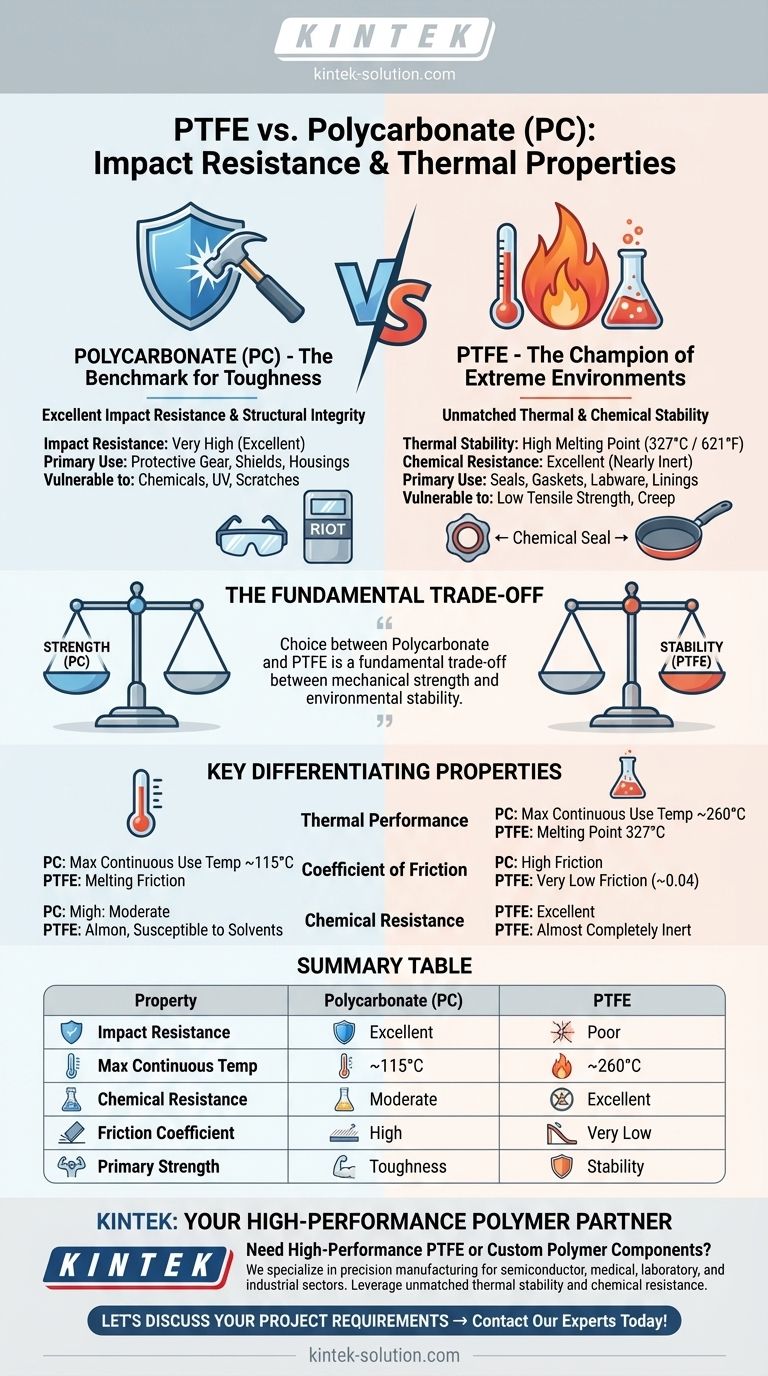

Summary Table:

| Property | Polycarbonate (PC) | PTFE |

|---|---|---|

| Impact Resistance | Excellent (Very High) | Poor (Low) |

| Max Continuous Use Temp | ~115°C (239°F) | ~260°C (500°F) |

| Chemical Resistance | Moderate | Excellent (Nearly Inert) |

| Coefficient of Friction | High | Very Low (~0.04) |

| Primary Strength | Toughness, Structural Integrity | Thermal/Chemical Stability, Non-stick |

Need High-Performance PTFE or Custom Polymer Components?

Selecting the right material is critical for your product's success. KINTEK specializes in the precision manufacturing of PTFE components—including seals, liners, and custom labware—for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We help you leverage PTFE's unmatched thermal stability and chemical resistance, or find the perfect polymer alternative for your needs. From initial prototypes to high-volume production, our expertise ensures quality and reliability.

Let's discuss your project requirements → Contact Our Experts Today!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability