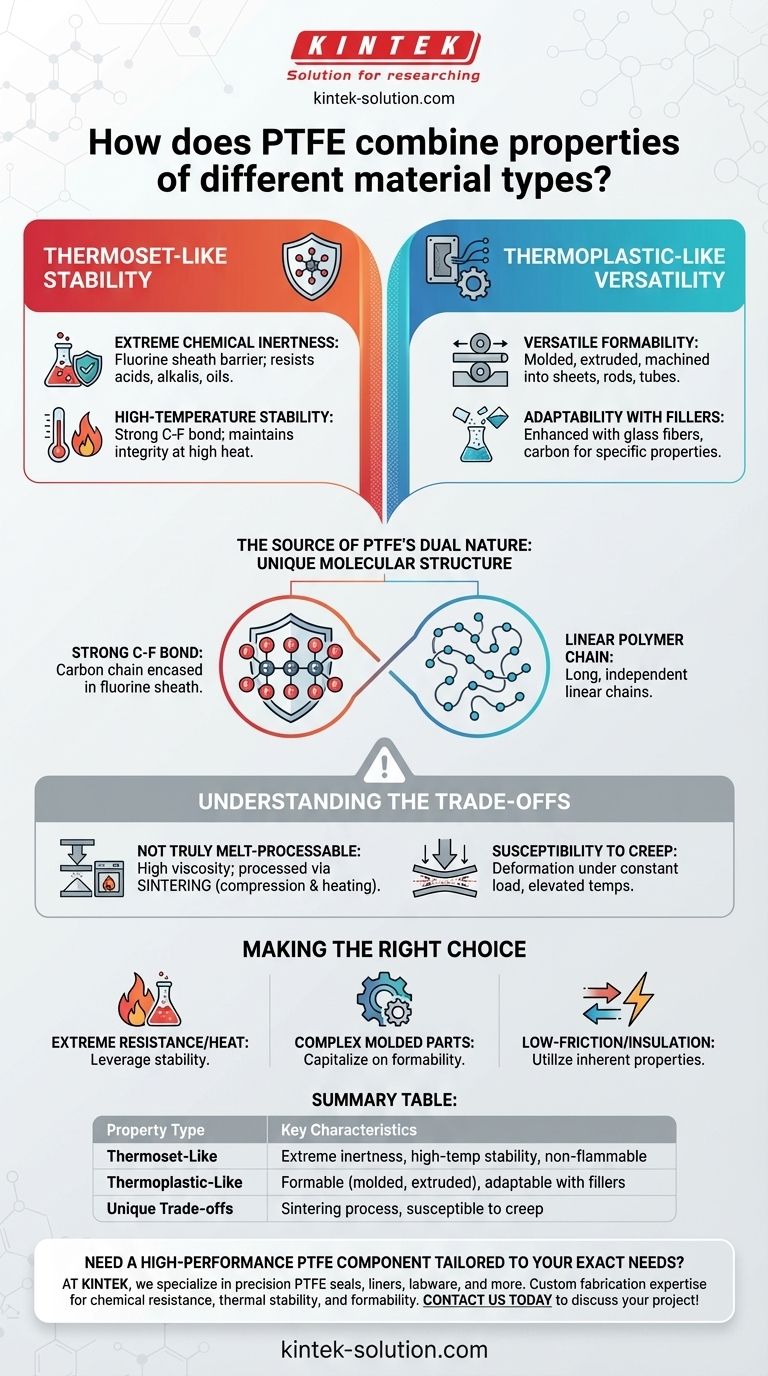

To put it simply, Polytetrafluoroethylene (PTFE) behaves like a hybrid material because its unique molecular structure gives it the best of two worlds. It possesses the extreme chemical and thermal resistance characteristic of a thermoset plastic, while also retaining the formability and versatility of a thermoplastic. This dual nature is why PTFE is one of the most adaptable high-performance polymers available.

The core of PTFE's power lies in its molecular foundation. An incredibly strong carbon-fluorine bond provides thermoset-like stability and inertness, while its linear, non-crosslinked polymer chain allows for thermoplastic-like versatility in manufacturing.

The Source of PTFE's Dual Nature

The properties of any polymer are a direct result of its molecular structure. For PTFE, two specific features work in tandem to create its unique profile.

The Carbon-Fluorine Bond

The bond between carbon and fluorine atoms is one of the strongest known in organic chemistry.

In PTFE, a chain of carbon atoms is completely encased in a sheath of fluorine atoms. This powerful bond is the source of its "thermoset-like" properties.

The Linear Polymer Chain

Unlike true thermosets, which form a rigid, cross-linked 3D network, PTFE molecules are long, independent linear chains.

This structure is characteristic of thermoplastics and is the key to its ability to be shaped and formed.

The "Thermoset" Characteristics Explained

The stability of the carbon-fluorine bond gives PTFE properties that are typically found in rigid, heat-cured thermoset materials.

Exceptional Chemical Inertness

The fluorine sheath acts as an impenetrable barrier, protecting the carbon backbone from chemical attack.

This is why PTFE has outstanding resistance to a vast range of materials, including concentrated acids, alkalis, oils, and hydrocarbons.

High-Temperature Stability

A significant amount of thermal energy is required to break the carbon-fluorine bond.

This gives PTFE a very high service temperature, allowing it to maintain its structural integrity and performance in environments where most thermoplastics would fail.

The "Thermoplastic" Characteristics Explained

Because its polymer chains are not chemically locked together, PTFE exhibits the formability and adaptability of a thermoplastic.

Versatile Formability

PTFE can be molded, extruded, and machined into a wide variety of standard forms, such as sheets, rods, tubes, and films.

This versatility allows it to be adapted to countless industrial component designs.

Adaptability with Fillers

Like many thermoplastics, PTFE can be compounded with fillers to enhance specific properties.

Adding glass fibers can increase wear resistance, while carbon can be added to improve thermal conductivity and strength.

Understanding the Trade-offs

While PTFE combines properties of both material types, it is not a perfect hybrid. It has its own unique processing requirements and limitations.

Not Truly Melt-Processable

Unlike common thermoplastics like nylon or polycarbonate, PTFE has an extremely high melt viscosity. It does not flow easily like a liquid when heated.

Because of this, it cannot be processed using conventional injection molding or extrusion. Instead, it is typically compressed and then heated in a process called sintering, which is more common to powdered metallurgy.

Susceptibility to Creep

Under a constant load, especially at elevated temperatures, PTFE can be subject to "creep," or slow deformation over time.

While strong, it is not as dimensionally rigid as many structural metals or true cross-linked thermosets under sustained mechanical stress.

Making the Right Choice for Your Goal

PTFE's unique profile makes it an exceptional problem-solver, but only when its properties are correctly aligned with the application's demands.

- If your primary focus is extreme chemical resistance or high temperatures: Leverage PTFE's thermoset-like stability, which far surpasses that of most common plastics.

- If your primary focus is creating complex, molded parts: Capitalize on PTFE's thermoplastic-like formability, but always account for its unique sintering process requirements.

- If your primary focus is low-friction or electrical insulation: Utilize PTFE’s inherent properties, which are a direct result of its stable molecular structure combined with its robust thermal performance.

Ultimately, understanding PTFE's dual nature allows you to leverage its unparalleled combination of stability and versatility for the most demanding applications.

Summary Table:

| Property Type | Key Characteristics |

|---|---|

| Thermoset-Like | Extreme chemical inertness, high-temperature stability, non-flammable |

| Thermoplastic-Like | Formable (molded, extruded), adaptable with fillers, versatile shapes |

| Unique Trade-offs | Processed by sintering (not melt-flow), susceptible to creep under load |

Need a high-performance PTFE component tailored to your exact needs?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our custom fabrication expertise ensures you get the perfect combination of chemical resistance, thermal stability, and formability for your application.

Contact us today to discuss your project and leverage PTFE's unique dual nature!

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers

- What is Teflon and what are its alternative names? Understanding PTFE, the Material Behind the Brand

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer

- How does PTFE react to common solvents? Discover Its Near-Total Chemical Immunity