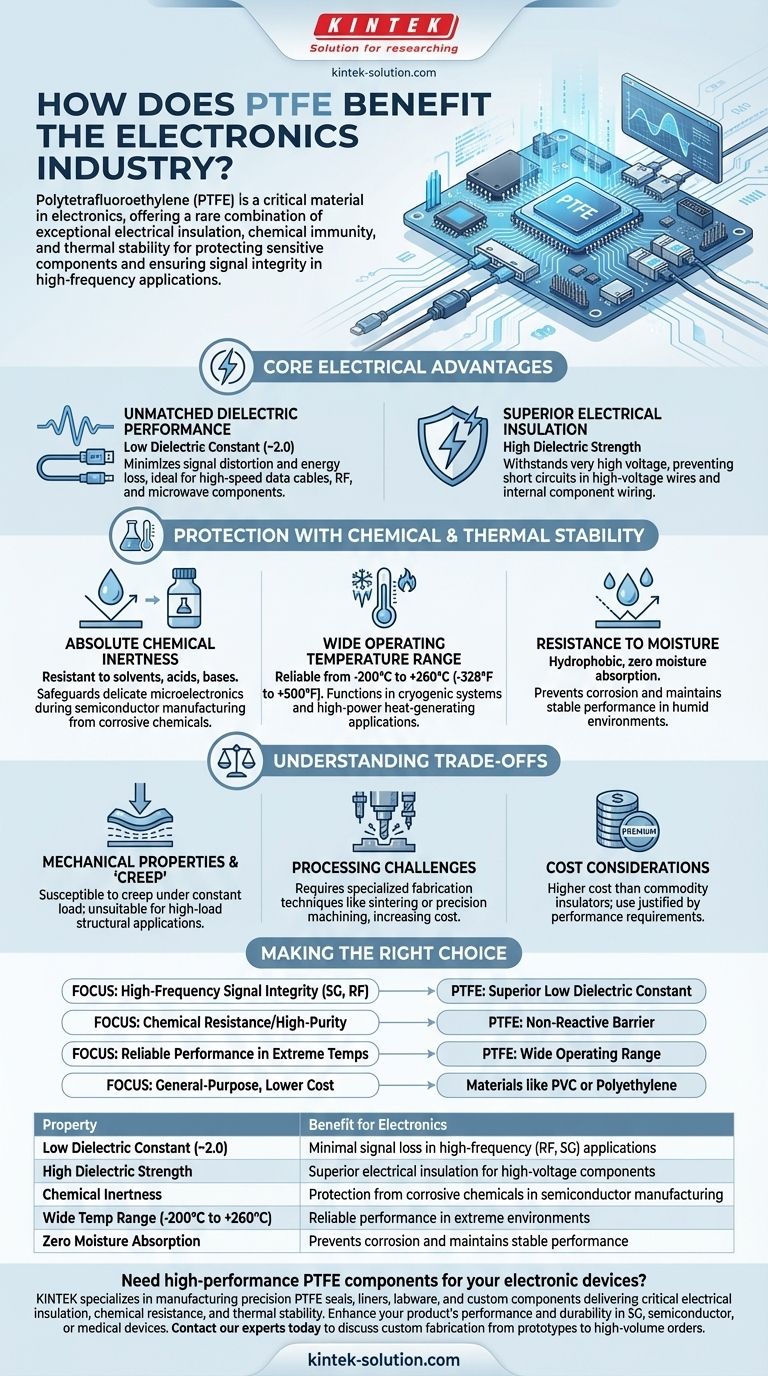

In short, Polytetrafluoroethylene (PTFE) is a critical material in the electronics industry due to its rare combination of properties. It provides exceptional electrical insulation, is virtually immune to chemical corrosion, and remains stable across an extremely wide range of temperatures. This allows it to protect sensitive components, ensure signal integrity in high-frequency applications, and provide reliable insulation where other materials would fail.

The core value of PTFE in electronics is not just one of its properties, but its unique ability to deliver elite electrical performance (low signal loss) and extreme resilience (chemical and thermal stability) simultaneously. It solves problems in applications where performance and reliability are non-negotiable.

The Core Electrical Advantages of PTFE

The primary reason PTFE is specified in demanding electronic applications is its superior electrical characteristics. These properties are fundamental to maintaining the integrity of electrical signals, especially as frequencies and data rates increase.

Unmatched Dielectric Performance

A material's dielectric constant measures its ability to store electrical energy. For high-frequency applications, a lower number is better, as it allows signals to travel faster with less distortion and energy loss.

PTFE has a very low dielectric constant of approximately 2.0, which remains stable across a wide frequency spectrum. This makes it an ideal insulator for high-speed data cables, RF, and microwave components where preserving signal clarity is paramount.

Superior Electrical Insulation

PTFE exhibits high dielectric strength, meaning it can withstand a very high voltage before it breaks down and allows current to pass through.

This makes it an excellent choice for insulating high-voltage wires and internal component wiring, effectively preventing short circuits and ensuring operational safety.

Protecting Components with Chemical and Thermal Stability

Modern electronics are often assembled using harsh chemicals and can operate in extreme environments. PTFE's inherent resilience provides a crucial layer of protection.

Absolute Chemical Inertness

PTFE is one of the most chemically non-reactive materials known. It is resistant to virtually all common solvents, acids, and bases.

This property is invaluable during semiconductor manufacturing, where components are exposed to corrosive etching chemicals. Using PTFE for fixtures and fluid handling ensures that no contamination or reaction occurs, safeguarding delicate microelectronics.

A Wide Operating Temperature Range

PTFE performs reliably across an exceptional temperature range, typically cited from below -200°C to a continuous service temperature of +260°C (-328°F to +500°F).

This allows PTFE-insulated components to function in everything from cryogenic systems to high-power applications that generate significant heat, without the material becoming brittle or degrading.

Resistance to Moisture

PTFE is hydrophobic, meaning it repels water. It has virtually zero moisture absorption.

In electronics, moisture can cause corrosion, create short circuits, and alter the electrical properties of insulating materials. PTFE's inability to absorb water ensures its performance remains consistent and reliable over the long term.

Understanding the Trade-offs

While PTFE is a high-performance material, it is not the solution for every problem. Understanding its limitations is key to using it effectively.

Mechanical Properties and "Creep"

PTFE is a relatively soft plastic. When subjected to a constant compressive force, it can slowly deform over time, a phenomenon known as creep. This makes it unsuitable for high-load, structural applications where dimensional stability is critical.

Processing and Fabrication Challenges

Unlike many common thermoplastics, PTFE cannot be easily melt-processed or injection-molded. It typically requires specialized and more costly fabrication techniques like sintering or precision machining, which can increase the final component cost.

Cost Considerations

PTFE is one of the most affordable fluoropolymers, but it is significantly more expensive than common commodity insulators like PVC or Polyethylene. Its use is typically justified only when its unique high-performance characteristics are a strict requirement.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary technical and budget goals.

- If your primary focus is high-frequency signal integrity (e.g., 5G, RF, microwave): PTFE is often the superior choice due to its exceptionally low and stable dielectric constant.

- If your primary focus is chemical resistance or high-purity manufacturing (e.g., semiconductor processing): PTFE's chemical inertness provides a non-reactive barrier that protects sensitive components.

- If your primary focus is reliable performance in extreme temperatures: PTFE's wide operating range ensures stability where many other plastics would fail.

- If your primary focus is general-purpose insulation at a lower cost: Materials like PVC or Polyethylene are likely more suitable, as the premium properties of PTFE may be unnecessary.

Ultimately, PTFE stands as a high-performance problem-solver, enabling technological progress in the most demanding electronic environments.

Summary Table:

| Property | Benefit for Electronics |

|---|---|

| Low Dielectric Constant (~2.0) | Minimal signal loss in high-frequency (RF, 5G) applications |

| High Dielectric Strength | Superior electrical insulation for high-voltage components |

| Chemical Inertness | Protection from corrosive chemicals in semiconductor manufacturing |

| Wide Temp Range (-200°C to +260°C) | Reliable performance in extreme environments |

| Zero Moisture Absorption | Prevents corrosion and maintains stable performance |

Need high-performance PTFE components for your electronic devices?

KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components that deliver the critical electrical insulation, chemical resistance, and thermal stability your industry demands. Whether you're developing 5G infrastructure, semiconductor equipment, or medical devices, our expertise in custom fabrication—from prototypes to high-volume orders—ensures your components meet the highest standards of reliability.

Contact our experts today to discuss how our PTFE solutions can enhance your product's performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments