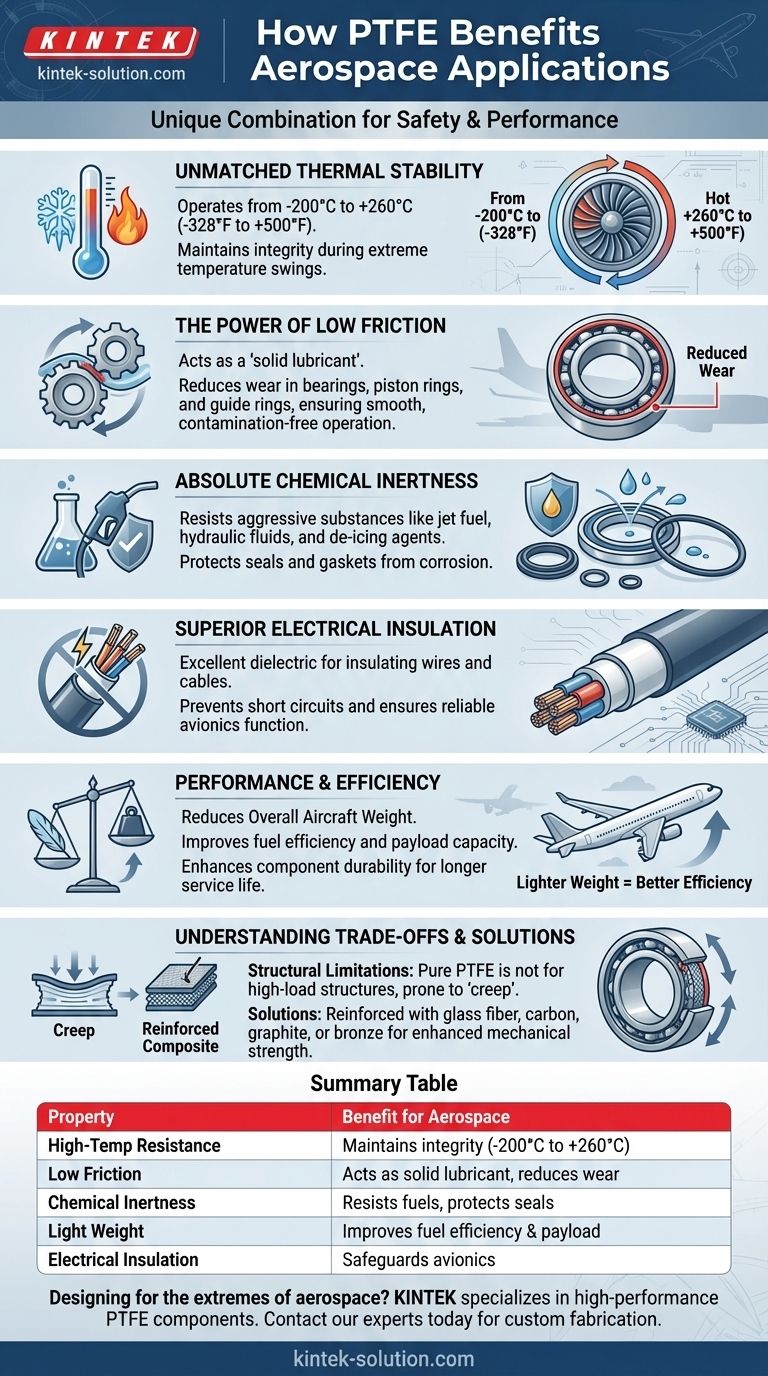

In the demanding world of aerospace engineering, Polytetrafluoroethylene (PTFE) provides a unique combination of benefits that are critical for safety and performance. Its value comes from its high-temperature resistance, extremely low coefficient of friction, chemical inertness, and light weight. These properties make it indispensable for coating engine components, gears, and bearings, where it reduces wear, improves durability, and helps lower the overall weight of the aircraft.

The true value of PTFE in aerospace isn't just a single property, but its rare ability to deliver reliable performance across the extreme temperature swings and harsh chemical environments of flight, from the ground to high altitudes.

Why PTFE Excels in Extreme Aerospace Environments

The operational conditions of an aircraft subject its components to incredible stress. PTFE is one of the few materials that can consistently perform under these circumstances, solving several core engineering challenges simultaneously.

Unmatched Thermal Stability

PTFE operates effectively across a vast temperature range, typically from -200°C to +260°C (-328°F to +500°F). This makes it ideal for components that experience drastic temperature variations during ascent, descent, and operation near high-heat engine parts.

Where other plastics would fail, PTFE maintains its structural integrity and performance characteristics, ensuring reliability.

The Power of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, earning it the role of a "solid lubricant."

This is critical for mechanical parts that cannot be lubricated with traditional oils or greases, which might contaminate sensitive systems. It is used in bearings, piston rings, and guide rings to ensure smooth, low-wear operation.

Absolute Chemical Inertness

Aerospace systems rely on aggressive substances like jet fuel, hydraulic fluids, and de-icing agents. PTFE is almost completely chemically inert and resists corrosion from these substances.

This ensures that seals, gaskets, and valve components do not degrade over time, a critical factor for both safety and long-term maintenance cycles.

Superior Electrical Insulation

Modern aircraft are filled with complex wiring and avionics systems. PTFE is an excellent dielectric, meaning it does not conduct electricity.

This property makes it a superior material for insulating wires and cables, preventing short circuits and ensuring the reliable function of mission-critical electronics, even at high temperatures.

A Key Contributor to Performance and Efficiency

Beyond surviving harsh conditions, PTFE actively improves the overall performance and efficiency of the aircraft.

Reducing Overall Aircraft Weight

Every kilogram matters in aerospace design. Replacing heavier metal components with lightweight PTFE parts or using PTFE coatings reduces the aircraft's total weight.

This directly translates to improved fuel efficiency and increased payload capacity.

Enhancing Component Durability

By creating non-stick, low-friction surfaces on gears and bearings, PTFE coatings significantly reduce wear and tear.

This extends the service life of critical parts, leading to longer intervals between maintenance and lower operational costs over the lifetime of the aircraft.

Understanding the Trade-offs

While its benefits are significant, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Structural Limitations

Pure PTFE is a relatively soft material and is not suitable for high-load structural applications. It can be prone to "creep," or deforming under sustained pressure.

Its primary strength is as a coating, liner, or component within a larger, more rigid assembly, not as a standalone structural element.

The Need for Reinforcement

To overcome its mechanical weaknesses, PTFE is often reinforced with other materials.

Fillers like glass fiber, carbon, graphite, or bronze can be added to the PTFE matrix. These composites enhance durability, wear resistance, and load-bearing capacity, making them suitable for more demanding mechanical applications like high-performance ball valves and bearings.

How to Apply PTFE in Aerospace Design

Choosing PTFE or a PTFE-based composite depends entirely on the specific engineering challenge you are solving.

- If your primary focus is reducing friction in moving parts: Specify PTFE coatings for bearings, gears, and seals to ensure smooth operation without traditional lubricants.

- If your primary focus is protecting components from harsh chemicals: Use PTFE for seals, gaskets, and valve linings that will be exposed to aggressive fuels or hydraulic fluids.

- If your primary focus is high-performance electrical insulation: Select PTFE for wire and cable jacketing, especially in high-temperature zones or near sensitive avionics.

- If your primary focus is a load-bearing application with low friction: Choose a reinforced PTFE composite (e.g., glass or carbon-filled) to gain the necessary mechanical strength and durability.

Ultimately, leveraging PTFE correctly allows engineers to build lighter, more durable, and more reliable aerospace systems.

Summary Table:

| Property | Benefit for Aerospace |

|---|---|

| High-Temperature Resistance | Maintains integrity from -200°C to +260°C, ideal for engine components and flight cycles. |

| Low Coefficient of Friction | Acts as a solid lubricant for bearings and gears, reducing wear without contamination. |

| Chemical Inertness | Resists jet fuels and hydraulic fluids, protecting seals and gaskets from corrosion. |

| Light Weight | Reduces aircraft weight, improving fuel efficiency and payload capacity. |

| Excellent Electrical Insulation | Safeguards avionics and wiring in high-temperature environments. |

Designing for the extremes of aerospace? KINTEK specializes in high-performance PTFE components for the semiconductor, medical, laboratory, and industrial sectors. We provide custom fabrication from prototypes to high-volume orders, ensuring precision and reliability for your most critical applications. Contact our experts today to discuss how our PTFE seals, liners, and labware can enhance your project's safety and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support