At its core, gland packing seals a system by being compressed. When force is applied to a stack of packing rings, they expand outwards to press against both the moving shaft and the stationary housing. This action fills the gap between the two components, creating a restrictive path that drastically limits fluid leakage.

The crucial insight is that gland packing is not designed to create a perfect, zero-leak seal. Its function is to create a controlled, minimal leak, where the slight passage of fluid or internal lubricant serves to cool and lubricate the packing, preventing catastrophic failure from friction and heat.

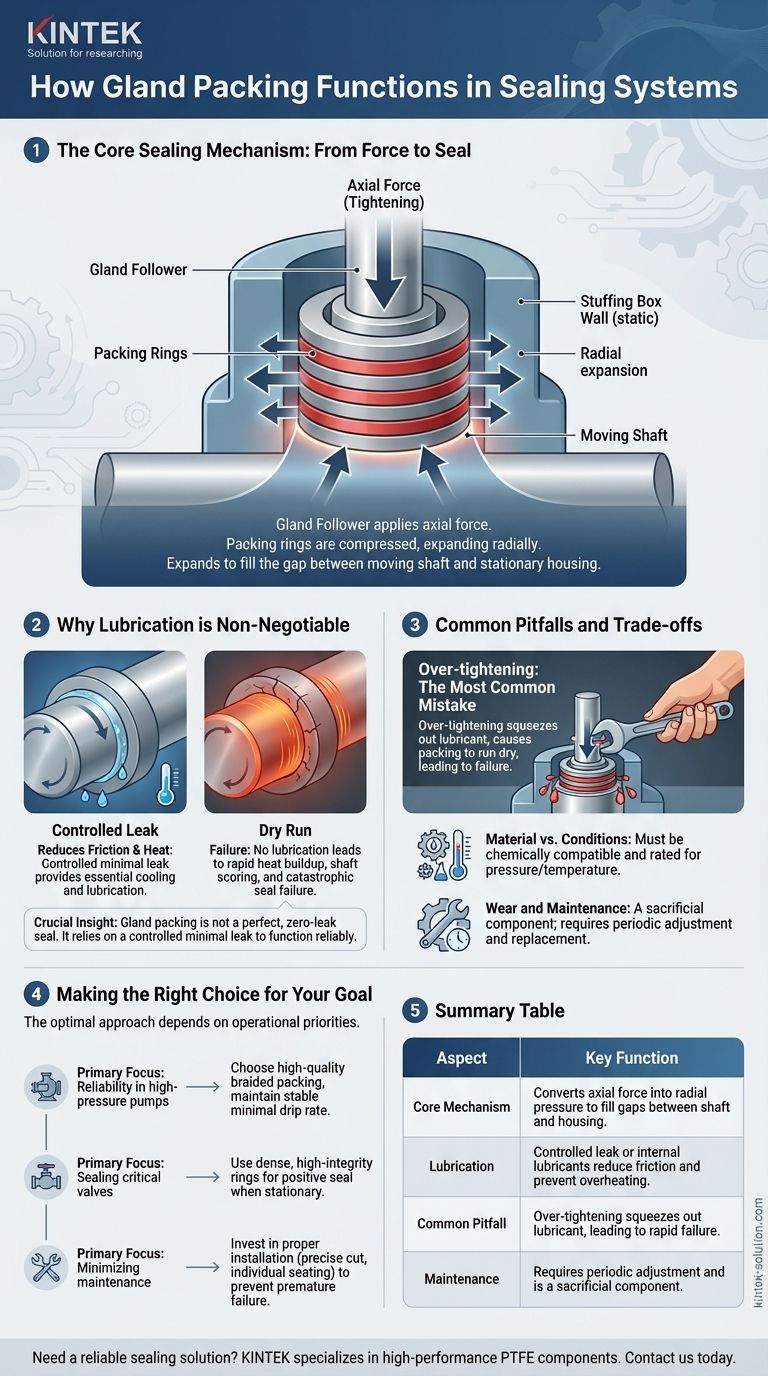

The Core Sealing Mechanism: From Force to Seal

The functionality of gland packing relies on a straightforward mechanical principle: converting axial force into radial pressure. This happens within a dedicated chamber called the stuffing box.

The Role of the Gland Follower

The process begins outside the seal. A component called a gland follower (or gland nut) is tightened against the stack of packing rings.

This tightening applies a predictable, controllable axial force along the length of the shaft.

Axial Force Becomes Radial Pressure

The packing rings, made of soft, conformable materials, are squeezed by this axial force.

This compression causes the rings to expand radially—outward towards the stuffing box wall and inward towards the moving shaft.

Sealing the Critical Gaps

This radial expansion is what creates the seal. The packing material firmly fills the clearance between the rotating component (the shaft) and the static component (the pump or valve housing).

This prevents the bulk of the process fluid from escaping along the shaft.

Why Lubrication is Non-Negotiable

A seal created by pure friction would fail almost instantly. Lubrication is the element that allows gland packing to function reliably over time.

Reducing Friction and Heat

A shaft can spin at thousands of RPM. The pressure from the packing creates immense friction, which generates destructive levels of heat.

Lubrication is essential to create a low-friction film between the packing and the shaft, allowing it to move freely without overheating.

The Function of Sacrificial Lubricants

Gland packing materials, such as PTFE or graphite-infused fibers, are impregnated with lubricants.

As the packing experiences pressure and heat during operation, this internal lubricant is slowly released, continuously maintaining the low-friction surface.

The Purpose of a Minimal "Leak"

In many applications, especially with pumps, a tiny, controlled drip rate (e.g., a few drops per minute) is intentional.

This drip of the process fluid itself provides additional cooling and lubrication to the sealing interface, extending the life of both the packing and the shaft.

Common Pitfalls and Trade-offs

Effective sealing with gland packing requires balancing competing forces. Misunderstanding this balance is the primary source of failure.

Over-tightening: The Most Common Mistake

The most frequent error is over-tightening the gland follower. Operators, seeing a leak, instinctively tighten it further to stop it completely.

This action squeezes out all the lubricant, causing the packing to run dry. The result is rapid heat buildup, shaft scoring, and complete seal failure.

Material vs. Operating Conditions

The packing material must be chemically compatible with the fluid it is sealing and rated for the system's temperature and pressure.

Using a standard PTFE packing in a high-temperature application, for instance, will cause it to degrade quickly and lose its sealing capability.

Wear and Required Maintenance

Gland packing is a sacrificial component by design. It is meant to wear out over time.

It requires periodic adjustment to maintain the correct compression and will eventually need to be fully replaced. Viewing it as a permanent "fit-and-forget" solution leads to unexpected downtime.

Making the Right Choice for Your Goal

The optimal approach to gland packing depends entirely on the equipment and your operational priorities.

- If your primary focus is reliability in high-pressure pumps: Choose a high-quality braided packing with excellent lubricant retention and follow a strict procedure to achieve a stable, minimal drip rate for cooling.

- If your primary focus is sealing critical valves: Use dense, high-integrity packing rings that can withstand high compression without extruding, ensuring a positive seal when the valve is not moving.

- If your primary focus is minimizing maintenance: Invest time in proper installation, ensuring rings are cut precisely and each one is seated individually, as this prevents premature failure more effectively than any other factor.

Mastering gland packing comes from understanding it as a dynamic seal that manages friction, not simply a plug that stops a leak.

Summary Table:

| Aspect | Key Function |

|---|---|

| Core Mechanism | Converts axial force into radial pressure to fill gaps between shaft and housing. |

| Lubrication | Controlled leak or internal lubricants reduce friction and prevent overheating. |

| Common Pitfall | Over-tightening squeezes out lubricant, leading to rapid failure. |

| Maintenance | Requires periodic adjustment and is a sacrificial component. |

Need a reliable sealing solution for your equipment? KINTEK specializes in manufacturing high-performance PTFE components, including custom gland packing and seals for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures optimal material compatibility and durability for your specific pressure and temperature requirements. Contact us today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are PTFE seals and why are they considered a reliable solution for extreme environments? Engineered for Harsh Conditions

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions