The defining benefit of chemical resistance in PTFE washers is operational integrity. This property allows them to maintain their physical structure and sealing capability when exposed to a vast range of aggressive substances, including acids, bases, and organic solvents. This ensures the washer will not degrade, corrode, or fail, preventing leaks and contamination in critical industrial applications.

While many materials offer sealing capabilities, PTFE's near-universal chemical inertness is its key differentiator. This property doesn't just prevent the washer from dissolving; it ensures the entire system remains uncontaminated, reliable, and safe over a long operational life.

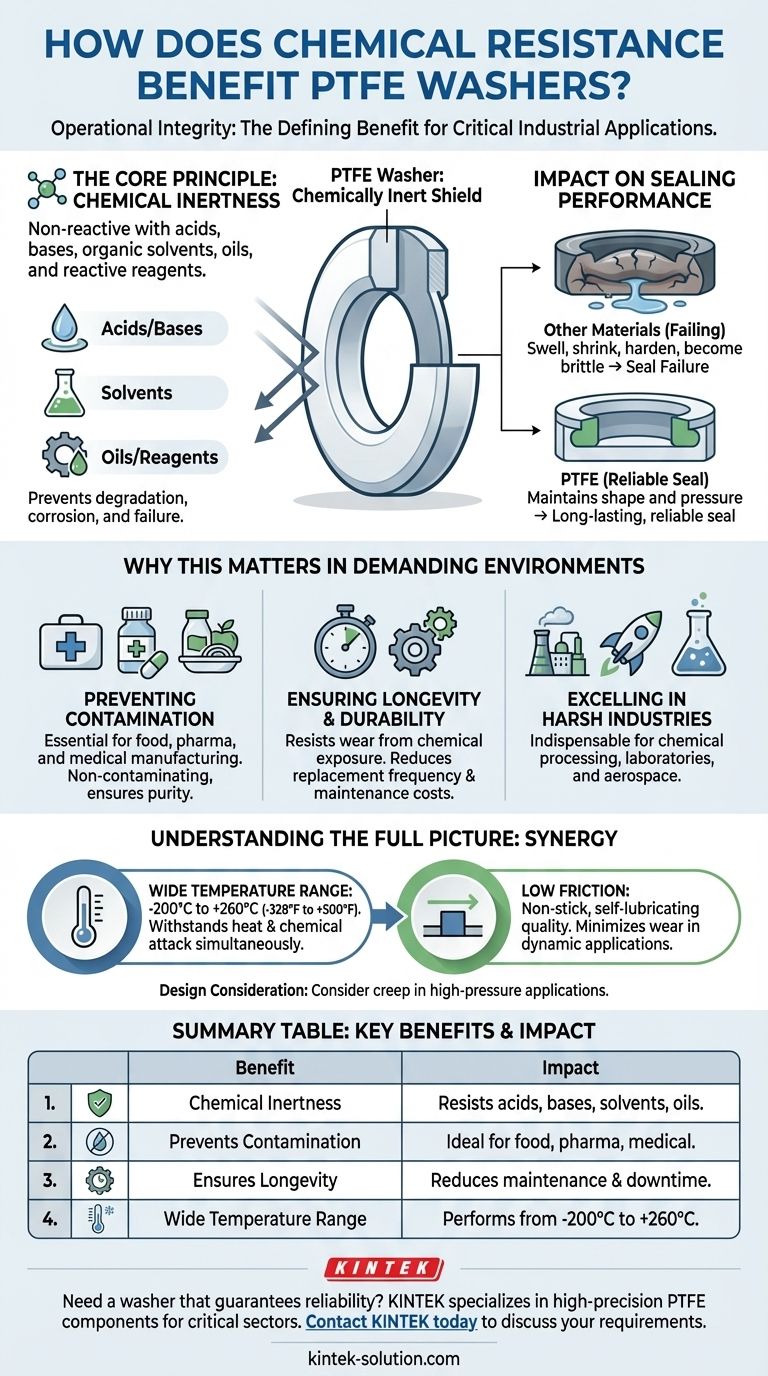

The Core Principle: Chemical Inertness

The exceptional performance of PTFE (Polytetrafluoroethylene) washers stems from a fundamental material property: they are chemically inert.

What is Chemical Inertness?

PTFE is one of the most non-reactive materials known. It does not react with the vast majority of chemicals it comes into contact with.

This means the washer acts as a stable, impassive barrier. It performs its mechanical function without being chemically altered by its environment.

A Spectrum of Resistance

This inertness provides protection against a wide spectrum of harsh substances commonly found in industrial settings.

This includes corrosive acids, aggressive bases, organic solvents, oils, and other reactive reagents that would quickly destroy most other materials.

Impact on Sealing Performance

Chemical attack causes other materials to swell, shrink, harden, or become brittle, which inevitably leads to seal failure.

Because PTFE resists these changes, it maintains a consistent shape and pressure. This ensures a reliable, long-lasting seal with minimal risk of leakage.

Why This Matters in Demanding Environments

The theoretical benefit of chemical resistance translates directly into practical advantages across several high-stakes industries.

Preventing System Contamination

In sectors like food, pharmaceutical, and medical manufacturing, purity is paramount.

PTFE's inertness is critical because the washer will not degrade or leach particles into the system. This non-contaminating nature ensures the final product remains pure and safe.

Ensuring Longevity and Durability

A washer that doesn’t corrode or wear down from chemical exposure lasts significantly longer.

This durability reduces the need for frequent replacements, which lowers maintenance costs and minimizes operational downtime.

Excelling in Harsh Industries

The unique properties of PTFE make it indispensable in environments like chemical processing plants, laboratories, and aerospace.

In these applications, components are constantly exposed to aggressive fluids, and material failure is not an option. PTFE provides the necessary reliability.

Understanding the Full Picture

Chemical resistance is PTFE's standout feature, but its value is amplified when considered alongside its other properties.

Synergy with Temperature Tolerance

PTFE washers function across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

Many chemical reactions are accelerated by heat. PTFE's ability to withstand both extreme temperatures and chemical attack simultaneously makes it a uniquely robust solution.

The Role of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a non-stick, self-lubricating quality.

In dynamic applications where parts move against the washer, this low friction minimizes wear, complementing the durability provided by its chemical resistance.

Important Design Considerations

While chemically superior, PTFE is a relatively soft material. Its mechanical properties, such as resistance to "creep" (deformation under sustained load), must be considered in high-pressure sealing applications to ensure a proper engineering fit.

Making the Right Choice for Your Application

To determine if PTFE's chemical resistance is the right solution, evaluate your primary operational goal.

- If your primary focus is system purity: PTFE is an excellent choice, as its inertness prevents leaching and contamination in food, medical, or pharmaceutical applications.

- If your primary focus is operational longevity in corrosive environments: PTFE's ability to withstand acids, bases, and solvents directly translates to reduced maintenance and a longer component lifespan.

- If your primary focus is a combination of chemical and thermal stress: PTFE's unique dual resistance to harsh chemicals and extreme temperatures makes it one of the most reliable options available.

Ultimately, selecting a PTFE washer is a decision to prioritize unwavering reliability in environments where other materials would quickly fail.

Summary Table:

| Key Benefit | Impact on Performance |

|---|---|

| Chemical Inertness | Resists reaction with acids, bases, solvents, and oils. |

| Prevents Contamination | Ideal for food, pharmaceutical, and medical applications. |

| Ensures Longevity | Reduces maintenance costs and operational downtime. |

| Wide Temperature Range | Performs from -200°C to +260°C, complementing chemical resistance. |

Need a washer that guarantees reliability in your most demanding applications?

KINTEK specializes in manufacturing high-precision PTFE components, including seals and washers, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a component engineered for superior chemical resistance and long-term performance.

Contact KINTEK today to discuss your specific requirements and discover how our PTFE solutions can protect your systems and enhance your operational integrity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials