The fundamental benefit of chemical resistance in PTFE Teflon washers is their ability to maintain structural integrity and sealing performance when exposed to nearly any corrosive substance. This property prevents the material from degrading, swelling, or dissolving, which ensures a reliable, long-lasting seal in the most demanding industrial environments.

The core value of a PTFE washer isn't just that it resists chemicals, but that it remains completely unaffected by them. This near-total inertness translates directly into operational reliability, preventing leaks, system contamination, and costly downtime.

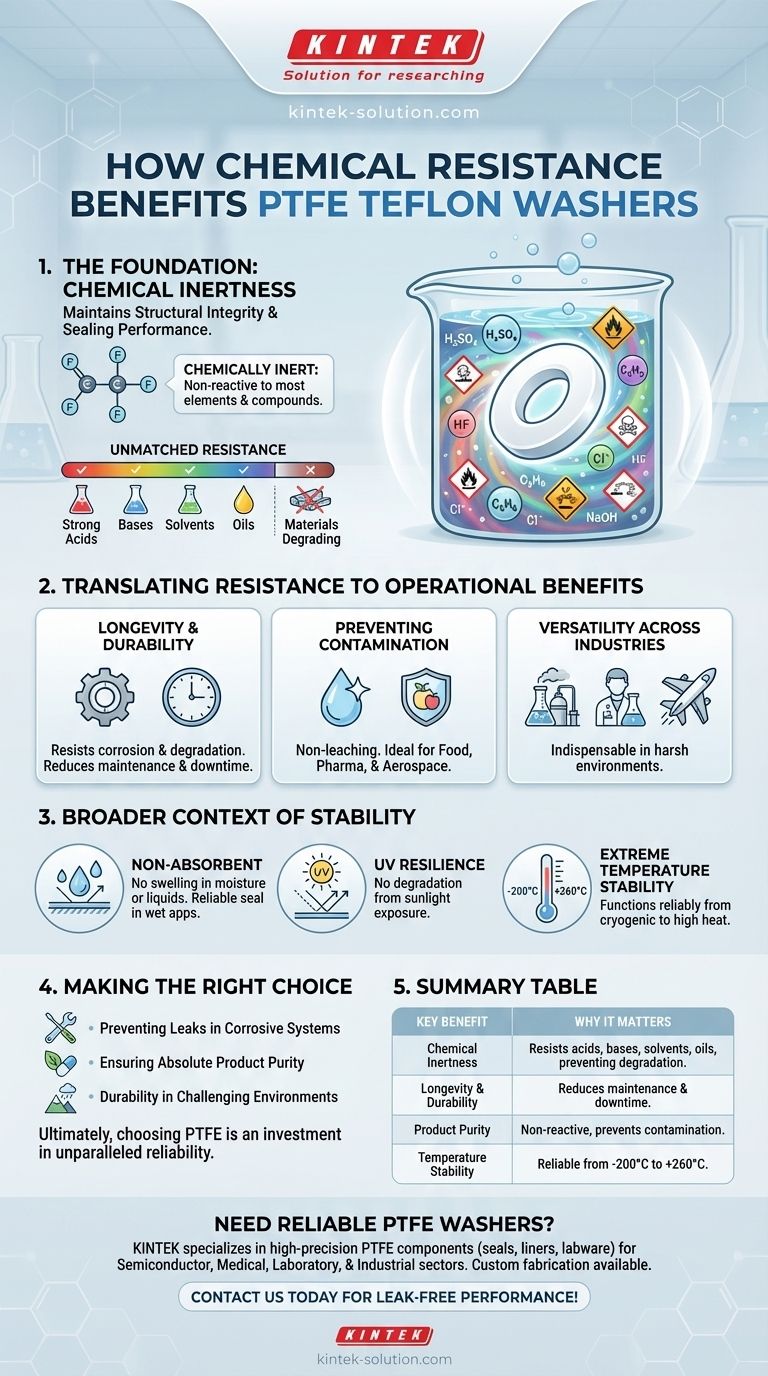

The Foundation of PTFE's Reliability: Chemical Inertness

The exceptional performance of PTFE washers stems from the material's unique molecular structure, which makes it one of the most non-reactive substances known.

What "Chemically Inert" Truly Means

PTFE is almost completely chemically inert, meaning it does not react with other chemical elements or compounds. This is why it is highly insoluble in most solvents and reagents.

Only a few highly specialized chemicals, such as certain alkali metals or powerful fluorinating agents under extreme conditions, can affect it. For virtually all industrial applications, it is considered non-reactive.

The Unmatched Spectrum of Resistance

This inertness provides tremendous resistance to a wide spectrum of chemicals. This includes aggressive substances like strong acids, bases, solvents, and oils.

Unlike other materials that might be resistant to one type of chemical but vulnerable to another, PTFE provides consistent performance across the board.

Why This Is Critical for Sealing

A washer’s primary job is to create a seal and prevent leaks. When a material reacts with a chemical, it can swell, shrink, soften, or become brittle.

Any of these changes will compromise the seal, leading to failure. Because PTFE does not react, it maintains its physical shape and mechanical properties, ensuring consistent sealing pressure and integrity over its entire service life.

Translating Resistance into Operational Benefits

The scientific property of chemical inertness delivers tangible, real-world advantages in industrial and commercial settings.

Unmatched Longevity and Durability

Because PTFE washers resist corrosion and chemical degradation, they do not wear out from chemical exposure. This drastically reduces the need for frequent replacements, lowering maintenance costs and minimizing system downtime.

Preventing System Contamination

In sensitive industries like food processing, pharmaceuticals, and aerospace, material purity is paramount. A washer that degrades can leach particles into the system, contaminating the final product.

PTFE's inertness ensures that nothing from the washer will enter the process fluid, protecting product quality and safety.

Versatility Across Demanding Industries

The ability to withstand nearly any chemical makes PTFE washers a default choice for a vast range of applications. They are indispensable in chemical processing plants, laboratories, and any environment where harsh or corrosive substances are present.

Understanding the Broader Context of Stability

While chemical resistance is the headline feature, it works in concert with other properties to make PTFE an exceptionally stable material.

Non-Absorbency in Moist Environments

PTFE washers do not absorb moisture or liquids. This prevents them from swelling in humid conditions or when submerged, ensuring a reliable seal is maintained even in wet applications.

Resilience to UV Exposure

For outdoor equipment or systems exposed to sunlight, UV resistance is critical. PTFE does not degrade or become brittle when exposed to ultraviolet radiation, maintaining its performance and integrity over time.

Extreme Temperature Stability

PTFE washers function reliably across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F). This allows them to maintain their chemical resistance and mechanical strength in both cryogenic and high-heat applications.

Making the Right Choice for Your Application

Selecting the right material is about matching its properties to your operational priorities.

- If your primary focus is preventing leaks in a highly corrosive system: PTFE's chemical inertness provides the most reliable long-term sealing performance against acids, bases, and solvents.

- If your primary focus is ensuring absolute product purity: PTFE's non-reactive and non-leaching nature makes it the ideal choice for food-grade, medical, or semiconductor applications.

- If your primary focus is durability in a challenging environment: The combination of chemical, UV, and temperature resistance ensures PTFE washers will not fail due to environmental factors.

Ultimately, choosing PTFE is an investment in unparalleled reliability and peace of mind.

Summary Table:

| Key Benefit | Why It Matters |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, solvents, and oils, preventing material degradation. |

| Longevity & Durability | Reduces maintenance costs and downtime by withstanding corrosive environments. |

| Product Purity | Non-reactive nature prevents contamination in sensitive industries like pharmaceuticals and food processing. |

| Temperature Stability | Performs reliably from -200°C to +260°C, maintaining seal integrity in extreme conditions. |

Need reliable PTFE washers that won't fail under chemical stress? KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services, from prototypes to high-volume orders, ensure you get chemically inert washers tailored to your exact needs. Contact us today to discuss your application and secure leak-free performance!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments