In short, the non-stick properties of PTFE prevent materials—especially sticky or viscous fluids—from building up on impeller surfaces. This core benefit directly translates into more consistent operational efficiency, significantly reduced maintenance cycles, and less downtime required for cleaning.

The fundamental advantage of using PTFE on impellers is its ability to create a self-cleaning surface. This prevents the gradual degradation of performance caused by material adhesion, ensuring the system runs closer to its designed specifications for longer periods.

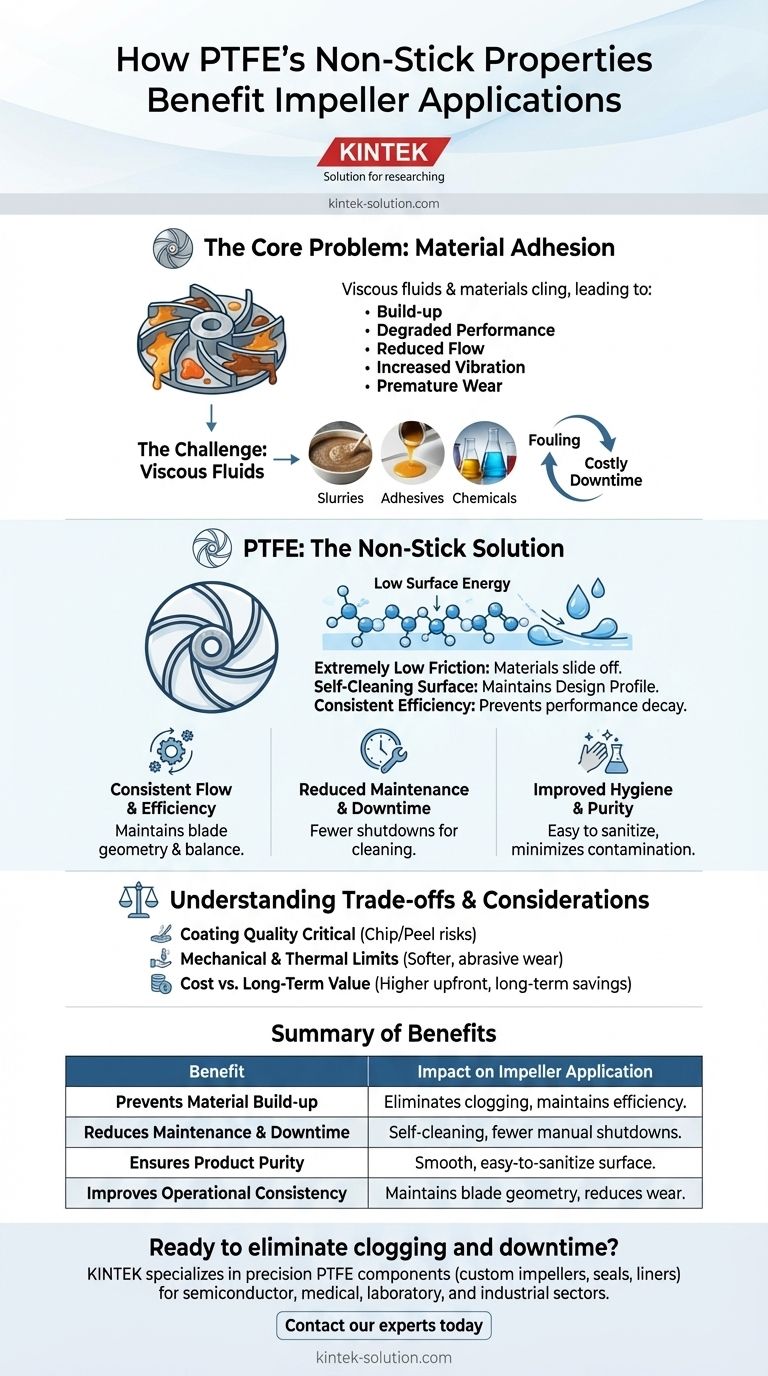

The Core Problem: Material Adhesion on Impellers

When fluids are mixed or pumped, any stickiness can cause material to accumulate on the impeller blades. This seemingly small issue has significant downstream consequences for both performance and maintenance.

How Build-up Degrades Performance

As material adheres to an impeller, it alters the blade's geometry and adds weight. This disrupts the carefully engineered fluid dynamics, reducing flow and mixing efficiency.

The added, uneven weight can also create an imbalance, leading to increased vibration, motor strain, and premature wear on bearings and seals.

The Challenge of Viscous Fluids

Substances like slurries, adhesives, food products, or certain chemicals have a natural tendency to cling to surfaces. On a standard metal impeller, this can lead to rapid clogging or "fouling."

This forces operators to either accept degraded performance or shut down the entire process for manual cleaning, both of which are costly.

How PTFE's Properties Solve the Problem

Polytetrafluoroethylene (PTFE) is a polymer with unique surface characteristics that directly counteract the problem of material adhesion. Its effectiveness stems from its fundamental chemistry.

Understanding PTFE's Low Surface Energy

PTFE has an extremely low coefficient of friction. In simple terms, its surface is so slick on a molecular level that other substances cannot get a proper grip.

This non-stick, or hydrophobic, quality means that materials are far more likely to slide off the surface rather than adhere to it, even under pressure.

Maintaining Consistent Flow and Efficiency

By preventing material build-up, a PTFE-coated or solid PTFE impeller maintains its original design profile during operation.

This ensures that the fluid dynamics remain consistent and the system operates at its intended efficiency without the gradual performance decay seen with standard impellers.

Improved Hygiene and Product Purity

In industries like food, beverage, and pharmaceuticals, preventing material build-up is critical for hygiene.

PTFE’s non-stick surface minimizes the areas where residue can linger and spoil, simplifying cleaning protocols and reducing the risk of cross-contamination between batches.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. Understanding its limitations is key to making an informed decision.

Coating Quality is Critical

In many cases, PTFE is applied as a coating to a metal impeller. The durability and lifespan of the non-stick properties are entirely dependent on the quality of that coating application.

A poorly applied coating can chip or peel, especially in abrasive environments, compromising its effectiveness.

Mechanical and Thermal Limits

While PTFE has a wide operating temperature range, it is softer than metal. It is not ideal for applications involving highly abrasive solids, which can wear away the surface over time.

You must ensure the specific grade of PTFE is suited to your process temperatures and chemical environment.

Cost vs. Long-Term Value

Impellers with PTFE components or coatings typically have a higher upfront cost than their stainless steel counterparts.

However, this initial investment must be weighed against the significant long-term savings from reduced downtime, lower cleaning labor costs, and more consistent production output.

Making the Right Choice for Your Application

To determine if PTFE is the correct choice, evaluate its primary benefits against your most critical operational goals.

- If your primary focus is handling sticky or viscous fluids: PTFE is an exceptional choice to prevent clogging, maintain flow, and ensure consistent mixing.

- If your primary focus is maximizing uptime: The self-cleaning nature of PTFE directly reduces the frequency of shutdowns needed for manual cleaning.

- If your primary focus is product purity and hygiene: PTFE provides a smooth, non-porous surface that is easy to clean and minimizes the risk of contamination.

Ultimately, leveraging PTFE's non-stick properties is a strategic decision to engineer a more reliable and efficient fluid-handling process.

Summary Table:

| Benefit | Impact on Impeller Application |

|---|---|

| Prevents Material Build-up | Eliminates clogging from sticky/viscous fluids, maintaining design efficiency. |

| Reduces Maintenance & Downtime | Self-cleaning surface minimizes shutdowns for manual cleaning. |

| Ensures Product Purity | Smooth, non-porous surface is easy to sanitize, ideal for food, pharma, and labs. |

| Improves Operational Consistency | Maintains blade geometry and balance, reducing vibration and wear. |

Ready to eliminate clogging and downtime in your process?

KINTEK specializes in precision PTFE components, including custom impellers, seals, and liners for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment runs at peak efficiency with minimal maintenance.

Contact our experts today to discuss a custom PTFE solution for your application!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials