In chemical processing, Teflon (PTFE) bushings are a critical component for ensuring operational reliability in harsh environments. Their primary benefits stem from a unique combination of extreme chemical inertness, high-temperature tolerance, and a naturally low coefficient of friction. This allows them to function reliably in applications like seals, stirrers, and pipeline supports where exposure to corrosive acids and solvents would cause other materials to fail.

Chemical plants operate under conditions where material failure is not merely an inconvenience but a significant safety and financial risk. Teflon bushings solve this core problem by providing a stable, non-reactive, and self-lubricating interface that protects equipment, prevents contamination, and minimizes costly downtime.

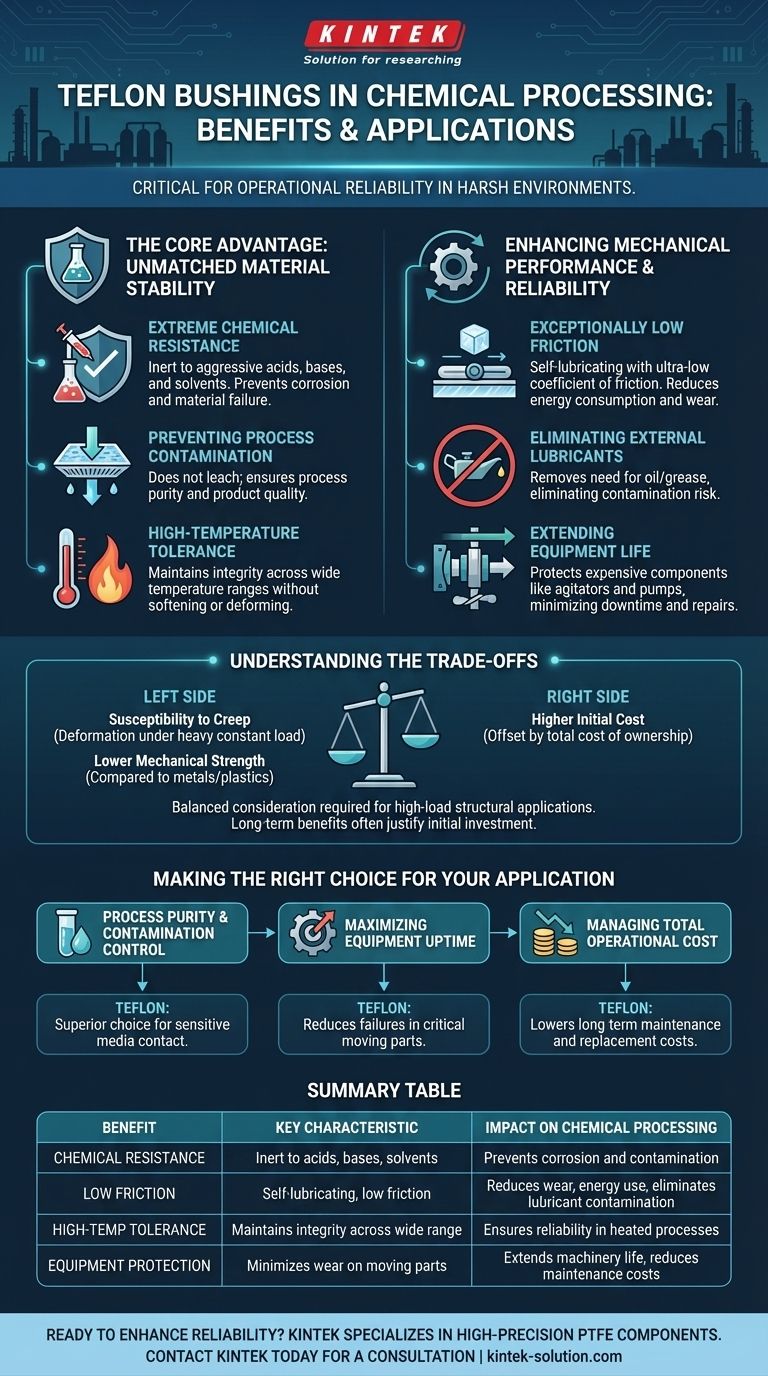

The Core Advantage: Unmatched Material Stability

The fundamental value of Teflon in a chemical plant is its ability to remain unchanged when everything around it is reactive and hostile.

Extreme Chemical Resistance

Teflon is virtually inert and does not react with the vast majority of industrial chemicals, including aggressive acids, bases, and solvents. This non-reactive nature prevents the bushing itself from corroding, degrading, or failing.

Preventing Process Contamination

Because Teflon does not degrade or leach material, it ensures the purity of the chemical process. This is critical for producing a consistent, high-quality final product without introducing unwanted impurities from equipment components.

High-Temperature Tolerance

Chemical processes often involve high temperatures. Teflon bushings maintain their structural integrity and physical properties across a wide temperature range, ensuring they do not soften, deform, or melt during operation.

Enhancing Mechanical Performance and Reliability

Beyond its chemical stability, Teflon's mechanical properties directly improve the function and lifespan of the machinery it's a part of.

Exceptionally Low Friction

Teflon has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" allows moving parts, such as the shafts in pumps or agitators, to move freely with minimal resistance.

This reduces energy consumption and, more importantly, minimizes wear on expensive equipment components.

Eliminating External Lubricants

The self-lubricating nature of Teflon bushings eliminates the need for oil or grease. This is a major advantage in chemical processing, as it removes the risk of a lubricant contaminating the process stream or reacting dangerously with the chemicals being used.

Extending Equipment Life

By reducing friction and wear between moving parts, Teflon bushings protect critical and costly equipment like agitator shafts and pump housings. This directly extends the service life of the machinery and reduces the frequency of major repairs.

Understanding the Trade-offs

While highly effective, Teflon is not a universal solution. Understanding its limitations is key to proper application.

Susceptibility to Creep

Under a constant, heavy load, Teflon can be susceptible to "creep" or cold flow, where the material slowly deforms over time. This must be considered in high-load structural applications.

Lower Mechanical Strength

Compared to metals or other engineering plastics, Teflon is a relatively soft material with lower compressive and tensile strength. It is best suited for low-friction bearing applications rather than high-stress structural roles.

Higher Initial Cost

Teflon bushings often have a higher upfront cost than components made from traditional materials. The financial justification lies in the total cost of ownership, factoring in reduced maintenance, zero lubrication costs, and minimized downtime.

Making the Right Choice for Your Application

The decision to use Teflon bushings should be based on a clear understanding of your primary operational goal.

- If your primary focus is process purity and preventing contamination: Teflon's chemical inertness makes it the superior choice for any parts in contact with aggressive or sensitive media.

- If your primary focus is maximizing equipment uptime: The self-lubricating and wear-resistant nature of Teflon reduces failures in critical moving parts like pumps, agitators, and valves.

- If your primary focus is managing total operational cost: While the initial investment may be higher, Teflon bushings reduce long-term expenses through lower maintenance, no lubrication needs, and less frequent replacement.

Ultimately, selecting Teflon bushings is a strategic decision to de-risk your operations and enhance long-term plant performance.

Summary Table:

| Benefit | Key Characteristic | Impact on Chemical Processing |

|---|---|---|

| Chemical Resistance | Inert to acids, bases, solvents | Prevents corrosion and process contamination |

| Low Friction | Self-lubricating, low coefficient of friction | Reduces wear, energy use, and eliminates lubricant contamination |

| High-Temp Tolerance | Maintains integrity across a wide temperature range | Ensures reliability in heated processes |

| Equipment Protection | Minimizes wear on moving parts | Extends machinery life and reduces maintenance costs |

Ready to enhance the reliability and purity of your chemical processing operations?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom bushings, seals, and liners, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment is protected from corrosive chemicals, operates with minimal maintenance, and maintains product integrity.

Let us provide a solution tailored to your specific needs, from prototype to high-volume production.

Contact KINTEK today for a consultation and see how our PTFE components can benefit your plant.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why are PTFE gaskets considered excellent for electrical insulation? Unmatched Reliability in Harsh Environments

- What can happen if excess pressure is applied during PTFE machining? Avoid Costly Part Failure and Deformation

- What are the key differences between monoaxial and multidirectional expanded PTFE? Choose the Right ePTFE for Your Seal

- How does tool selection affect PTFE surface finish? Achieve a Flawless Finish with the Right Tools

- How does the PTFE lining extend the valve's service life? The Ultimate Shield Against Corrosion and Wear

- What role does the PTFE sheet play in design transfer? Achieve Flawless, Professional Results

- What are the main properties of PTFE that make it valuable as a sealing material? Discover the Ultimate Sealing Solution

- What are the benefits of using bronze as a filler in PTFE? Enhance Wear, Creep & Thermal Performance