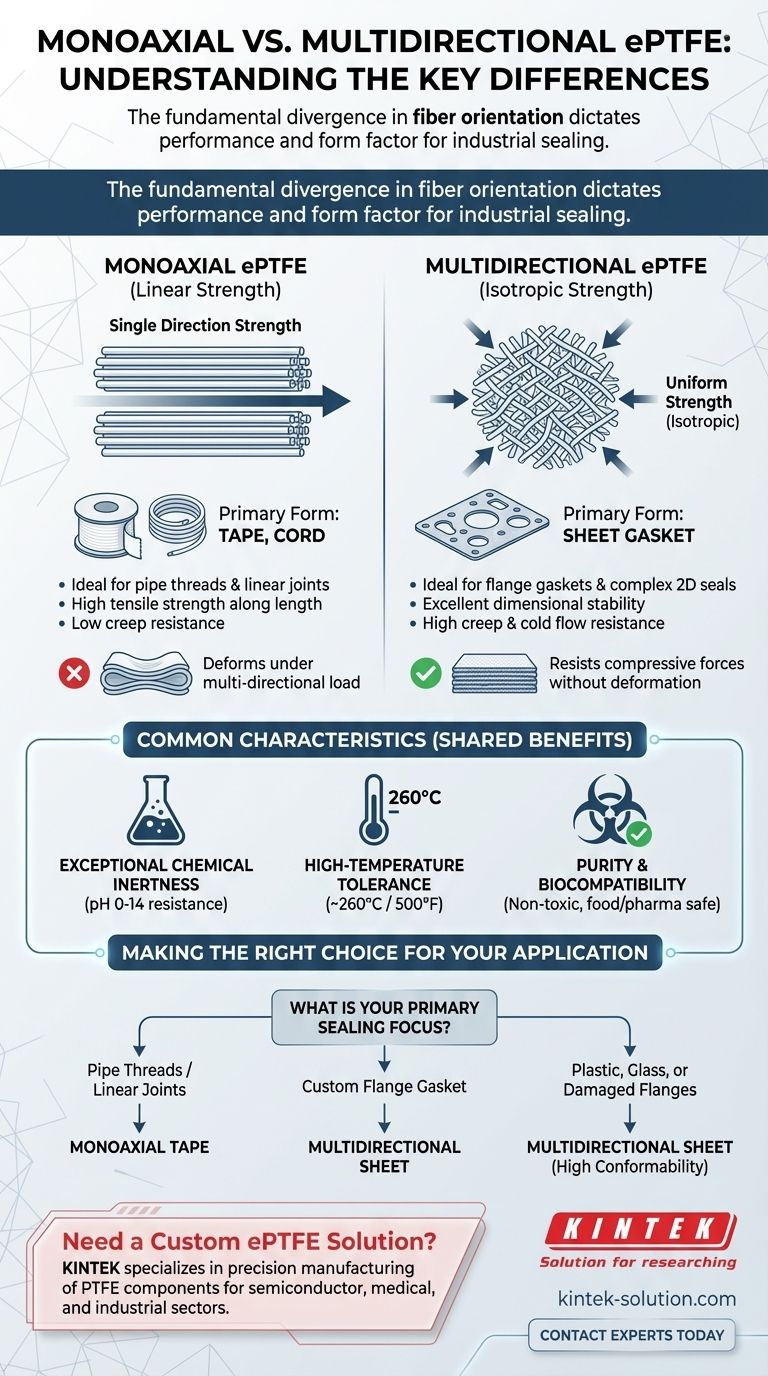

At its core, the difference between monoaxial and multidirectional expanded PTFE (ePTFE) is the orientation of its internal microfiber structure. Monoaxial ePTFE has fibers aligned in a single direction, making it ideal for tapes and cords. In contrast, multidirectional ePTFE has a uniform, web-like fiber structure in all directions, which provides the mechanical stability required for sheet gasketing materials.

The choice is dictated by mechanical load and form factor. Monoaxial ePTFE is designed for simple, linear seals where strength is needed in one direction, while multidirectional ePTFE is engineered for complex, two-dimensional seals that must resist compressive forces from all directions without deforming.

The Fundamental Difference: Fiber Orientation

The expansion process of PTFE creates a microporous material with a structure of nodes interconnected by fine fibers. The method of expansion determines the final properties of the material.

Monoaxial ePTFE: Linear Strength

In monoaxially expanded PTFE, the manufacturing process stretches the material in a single direction.

This aligns all the microfibers along that one axis. The result is a material with high tensile strength along its length but limited strength in the perpendicular direction, making it ideal for products like sealing tape or cords.

Multidirectional ePTFE: Isotropic Strength

Multidirectional ePTFE is created using a process that expands the material in multiple directions.

This technique produces a uniform, mesh-like structure where fibers are oriented evenly in all directions. This isotropic (same in all directions) strength is what allows the material to be formed into stable sheets that resist deformation under pressure.

How Structure Dictates Performance and Form

The difference in fiber orientation directly translates to how each material performs in an industrial setting and the forms in which it is available.

Mechanical Stability and Creep Resistance

Multidirectional ePTFE exhibits significantly better dimensional stability. Its uniform structure provides excellent resistance to cold flow and creep, which is the tendency of a material to deform slowly under constant stress.

This property is critical for gaskets on bolted flanges, which must maintain a consistent seal under long-term compressive load. Monoaxial tape is not designed to distribute this type of load and would deform.

Conformability and Form Factor

The multidirectional structure allows ePTFE to be manufactured as a sheet. These sheets can be easily cut or punched into complex, custom gasket shapes without losing their structural integrity.

This makes multidirectional ePTFE highly conformable, ideal for sealing irregular, damaged, or wide flanges. Monoaxial ePTFE, by contrast, is supplied as a tape or cord perfectly suited for wrapping pipe threads or fitting into linear grooves.

Common Characteristics of All ePTFE

While their mechanical properties differ, both monoaxial and multidirectional ePTFE retain the outstanding core benefits of the base polymer.

Exceptional Chemical Inertness

Both types offer superior chemical resistance across nearly the entire pH range (0-14). The only common exceptions are molten alkali metals and elemental fluorine. This ensures the material will not degrade or contaminate the process media.

High-Temperature Tolerance

Expanded PTFE performs reliably in high-temperature applications, with a typical maximum service temperature of around 260°C (500°F).

Purity and Biocompatibility

ePTFE is non-toxic, chemically inert, and does not contaminate or discolor end products. These properties, along with its excellent biocompatibility, make it suitable for use in medical devices, pharmaceuticals, and food processing applications.

Making the Right Choice for Your Application

Selecting the correct type of ePTFE is straightforward once you define the mechanical requirements of the seal.

- If your primary focus is sealing pipe threads or linear joints: Monoaxially expanded PTFE tape is the correct choice for its simplicity and high strength in the direction of wrapping.

- If your primary focus is creating a custom gasket for a flange: Choose multidirectionally expanded PTFE sheet for its dimensional stability and resistance to creep under compression.

- If your primary focus is sealing plastic, glass, or damaged flanges: Multidirectional ePTFE's excellent conformability makes it ideal for creating a reliable seal on sensitive or imperfect surfaces with low bolt loads.

Understanding this core structural difference empowers you to select the precise material engineered for your specific sealing challenge.

Summary Table:

| Feature | Monoaxial ePTFE | Multidirectional ePTFE |

|---|---|---|

| Fiber Structure | Fibers aligned in one direction | Uniform, web-like structure in all directions |

| Primary Form | Tape, Cord | Sheet |

| Key Strength | High tensile strength in one direction | Isotropic strength & dimensional stability |

| Ideal For | Pipe threads, linear seals | Flange gaskets, complex 2D seals |

| Creep Resistance | Low | High |

Need a Custom ePTFE Solution for Your Application?

Choosing between monoaxial tape and multidirectional sheet is just the start. KINTEK specializes in the precision manufacturing of PTFE components, including custom-expanded PTFE seals, liners, and labware.

We serve the semiconductor, medical, laboratory, and industrial sectors, delivering solutions from prototypes to high-volume production. Our expertise ensures you get the right material and form factor for superior chemical resistance, high-temperature performance, and reliable sealing.

Let's engineer your perfect seal. Contact our experts today to discuss your requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What makes PTFE lined valves suitable for handling aggressive media? Superior Chemical Resistance for Harsh Fluids

- What is a PTFE sliding elastomeric bearing? A Guide to Managing Large Structural Movements

- What is the tensile strength of Teflon balls? Leverage Its Unique Properties for Your Application

- What happens if standard PTFE is used for both upper and lower members of a slide bearing? Avoid Premature Failure with the Right Design

- What is the maximum working temperature for Teflon balls? Ensuring Safe and Reliable Performance

- What types of applications commonly use PTFE rotary seals? Solve Extreme Chemical, Temperature, and Speed Challenges

- What are the machining advantages of PTFE rod? Achieve Cost-Effective, Complex Parts

- What are the temperature resistance properties of PTFE O-rings? Withstand -200°C to 260°C Extremes