Tool selection is paramount for PTFE surface finish because the material's unique softness and low friction cause it to tear and deform rather than chip cleanly like metal. Success requires ultra-sharp cutting edges with specific geometry designed to slice the material cleanly, minimizing friction and heat buildup that would otherwise ruin the surface quality.

The core principle for machining Polytetrafluoroethylene (PTFE) is to use tools that cleanly shear the polymer fibers instead of pushing or tearing them. This is achieved with exceptionally sharp cutting edges, low rake angles, and a polished tool surface to minimize friction and deformation.

The Core Challenge: Machining a Soft, Low-Friction Polymer

PTFE's desirable properties, like its non-stick surface, also make it notoriously difficult to machine to a high-quality finish. Understanding why it behaves this way is the first step to selecting the right tool for the job.

Why PTFE is Prone to Tearing

Unlike rigid materials that form a distinct chip when cut, PTFE's soft structure tends to deform and stretch under pressure. A dull or improperly shaped tool will push the material ahead of the cutting edge, causing it to tear away unpredictably and leave a fuzzy or ragged surface.

The True Enemy: Frictional Heat

PTFE has a low thermal conductivity, meaning it doesn't dissipate heat well. Friction from the cutting tool generates localized heat, which can easily cause the material to soften, deform, or even melt, destroying the part's dimensional accuracy and surface integrity.

Key Tool Characteristics for a Superior PTFE Finish

To counteract the material's natural tendencies, your tooling must be optimized for three specific characteristics.

Uncompromising Sharpness

This is the most critical factor. The tool must be ultra-sharp to initiate a clean slicing action with minimal force. A microscopic dull spot will immediately begin to plow through the material rather than cut it.

Both high-speed steel (HSS) and carbide-tipped tools are effective, provided they are ground to a razor-fine edge.

The Right Geometry: Low Rake Angles

The recommended rake angle is between 0° and 15°. A low or neutral rake angle prevents the tool from "digging into" the soft material, which would cause it to grab and tear. This geometry promotes a shearing action that slices the material cleanly at the cutting point.

Polished Cutting Edges

A polished or honed cutting edge further reduces friction between the tool and the workpiece. This subtle but important feature minimizes material buildup on the tool and lowers heat generation, directly contributing to a smoother finish.

Understanding the Trade-offs and Common Pitfalls

Even with the right tool geometry, other factors can compromise your results. Awareness of these trade-offs is crucial for consistent success.

Tool Material: Carbide vs. High-Speed Steel

Carbide tools offer superior wear resistance and will hold their sharp edge for much longer in a production environment. However, HSS can often be honed to an even sharper "razor" edge, making it an excellent choice for one-off parts or prototypes where absolute finish is the priority.

Forgetting Post-Machining Processes

For the highest possible surface quality, a secondary finishing step may be required. Mechanical polishing with a soft felt pad and an ultra-fine abrasive like diamond paste can refine the machined surface, but you must avoid generating excess heat during this process.

Neglecting Speeds and Feeds

The best tool in the world will fail if not used correctly. High rotational speeds and aggressive feed rates can generate excessive heat and pressure, negating the benefits of a sharp, well-designed tool. Always start with conservative parameters and adjust based on the resulting finish.

Making the Right Choice for Your Goal

Your specific objective will determine the optimal approach to tool selection and processing.

- If your primary focus is the best possible as-machined finish: Use a new or freshly ground carbide tool with a polished, low rake angle (0-15°) edge to ensure a consistently clean cut.

- If your primary focus is prototyping or low-volume work: An ultra-sharp high-speed steel (HSS) tool is an excellent and cost-effective choice, but be prepared to check for wear and re-sharpen frequently.

- If your primary focus is achieving a mirror-like or optical-grade surface: Combine precise machining with a secondary, low-pressure polishing step using soft pads and a fine diamond compound.

Ultimately, treating PTFE as a delicate material that must be sliced—not forced—is the key to achieving a flawless surface finish.

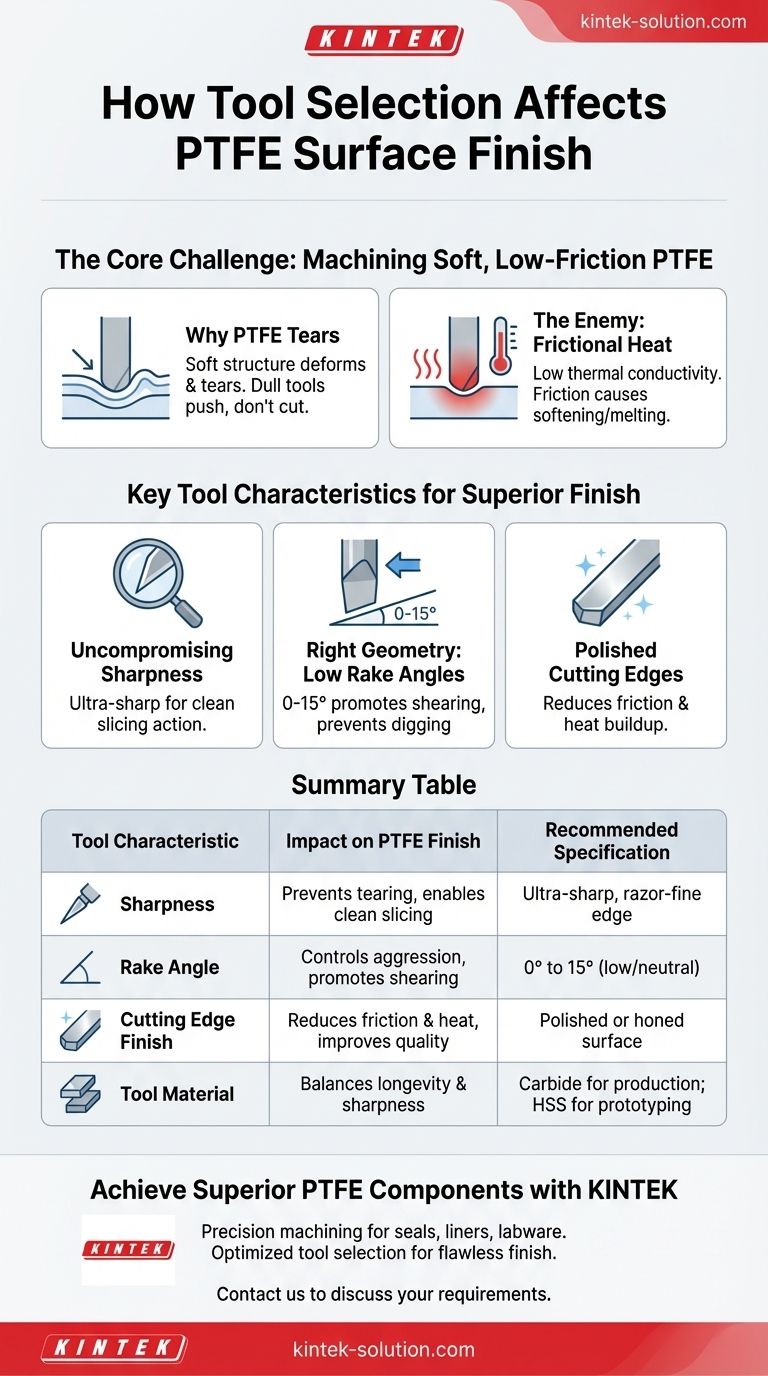

Summary Table:

| Tool Characteristic | Impact on PTFE Finish | Recommended Specification |

|---|---|---|

| Sharpness | Prevents tearing and deformation; enables clean slicing. | Ultra-sharp, razor-fine edge. |

| Rake Angle | Controls cutting aggression; promotes shearing over digging. | 0° to 15° (low/neutral). |

| Cutting Edge Finish | Reduces friction and heat buildup, improving surface quality. | Polished or honed surface. |

| Tool Material | Balances edge longevity and ultimate sharpness. | Carbide for production; HSS for prototyping. |

Achieve superior PTFE components with KINTEK's precision machining expertise.

PTFE's unique properties demand specialized tooling and a meticulous approach to prevent tearing and heat damage. KINTEK manufactures high-quality PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. We prioritize precision production, using optimized tool selection and parameters to ensure a flawless surface finish on every part, from custom prototypes to high-volume orders.

Let us apply this expertise to your project. Contact our team today to discuss your specific requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments