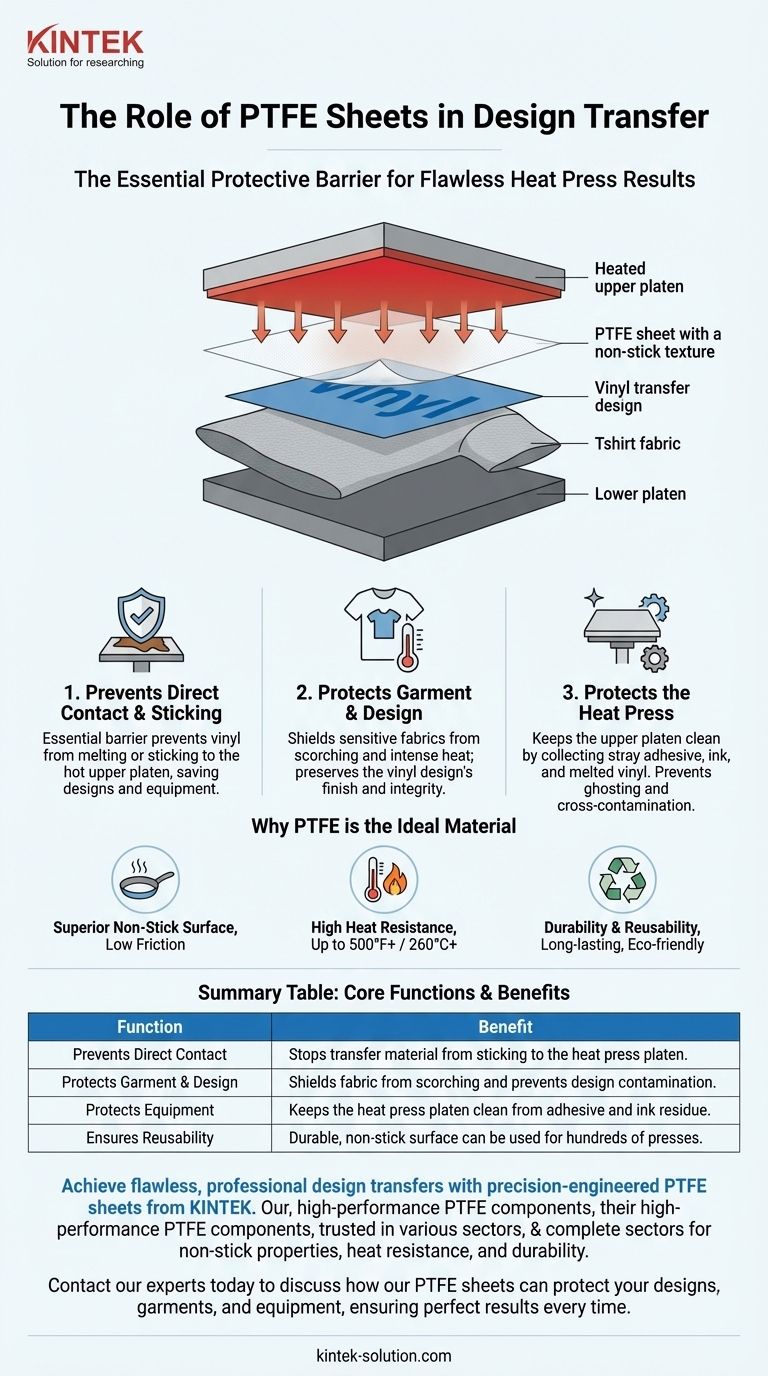

In design transfer using a heat press, a PTFE sheet functions as an essential protective barrier. It is placed between the heated upper platen and the transfer material (like vinyl), preventing the materials from melting, sticking, or scorching during the application process.

The core purpose of a PTFE sheet is to ensure a clean, high-quality design transfer by preventing direct contact. This single action protects both the garment and the heat press equipment from damage, making it a non-negotiable tool for consistent results.

The Core Functions of a PTFE Sheet

A Polytetrafluoroethylene (PTFE) sheet, often known by the brand name Teflon, is more than just a simple accessory. It plays several critical roles in achieving a professional-grade transfer.

Preventing Direct Contact and Sticking

The primary function is to prevent direct contact between the hot metal platen and the heat transfer vinyl (HTV) or substrate.

Without this barrier, the vinyl could easily melt and adhere to the press itself, ruining both the design and the equipment.

Protecting the Garment and Design

The sheet shields the garment from the intense, direct heat, which can cause scorching or yellowing on sensitive fabrics.

It also protects the surface of the vinyl design, ensuring it doesn't overheat and that no residue from the platen contaminates its finish.

Protecting the Heat Press

Just as it protects the garment, the sheet also protects your investment in the heat press.

Any stray adhesive, ink, or melted vinyl will stick to the reusable PTFE sheet instead of the upper platen. This keeps the platen clean and prevents ghosting or residue from being transferred to subsequent projects.

Why PTFE is the Ideal Material

PTFE is not used by accident; its specific material properties make it uniquely suited for heat transfer applications.

Superior Non-Stick Surface

PTFE has an extremely low coefficient of friction, making it one of the most effective non-stick surfaces available. This ensures that even at high temperatures, nothing will fuse to it.

High Heat Resistance

The material can easily withstand the typical temperatures used in heat pressing (up to 500°F / 260°C or more) without degrading, melting, or releasing harmful fumes.

Durability and Reusability

A single PTFE sheet is highly durable and can be wiped clean and reused for hundreds or even thousands of presses. This longevity reduces material waste and makes it a cost-effective and environmentally sound choice compared to disposable alternatives like parchment paper.

Common Pitfalls to Avoid

While essential, using a PTFE sheet requires understanding its role in the overall process to avoid common mistakes.

It's a Tool, Not a Cure-All

A PTFE sheet cannot compensate for incorrect temperature, pressure, or time settings. You must still follow the specific application instructions for your heat transfer material.

Potential for Minor Heat Buffering

The sheet introduces a very thin layer between the heat source and the design. In some cases, you may need to increase the temperature or dwell time slightly (e.g., +5-10°F or +1-2 seconds) to ensure a proper transfer, but always test first.

Keep It Clean and Flat

Wrinkles, creases, or debris on your PTFE sheet can be impressed onto your final design, leaving unwanted textures or marks. Always store it flat or loosely rolled and wipe it clean before use.

Making the Right Choice for Your Goal

Using a PTFE sheet is a simple step that separates amateur results from professional ones. Its role is straightforward but fundamental to the process.

- If your primary focus is quality and consistency: Always use a clean PTFE sheet to guarantee a flawless finish and prevent scorching on every press.

- If your primary focus is equipment longevity: Use the sheet to protect your heat press platen from residue, dramatically reducing cleaning time and preventing cross-contamination between jobs.

- If your primary focus is cost-effectiveness: Invest in a quality PTFE sheet for its reusability, which eliminates the recurring cost and waste of disposable barrier sheets.

Ultimately, the PTFE sheet is an indispensable tool that ensures the integrity of your design, your garment, and your equipment.

Summary Table:

| Function | Benefit |

|---|---|

| Prevents Direct Contact | Stops transfer material from sticking to the heat press platen |

| Protects Garment & Design | Shields fabric from scorching and prevents design contamination |

| Protects Equipment | Keeps the heat press platen clean from adhesive and ink residue |

| Ensures Reusability | Durable, non-stick surface can be used for hundreds of presses |

Achieve flawless, professional design transfers with precision-engineered PTFE sheets from KINTEK.

Our high-performance PTFE components are trusted by professionals in the semiconductor, medical, laboratory, and industrial sectors for their superior non-stick properties, exceptional heat resistance, and unmatched durability. Whether you need custom fabrication for a unique application or high-volume orders for consistent production, KINTEK delivers the quality and reliability your process demands.

Contact our experts today to discuss how our PTFE sheets can protect your designs, garments, and equipment, ensuring perfect results every time.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the considerations for managing PTFE's creep and thermal expansion? Ensure Dimensional Stability & Performance

- What are the non-stick properties of PTFE impellers? Achieve Purity & Prevent Buildup in Critical Mixing

- What are the key benefits of PTFE O-rings? Superior Sealing for Extreme Conditions

- How does PTFE laminate differ from FR4 in terms of environmental and chemical resistance? Superior Stability for Harsh Conditions

- What are the features of PTFE with a Proprietary Organic Fill? Protect Soft Metals with Low-Friction Performance

- What are common industrial applications of machined Teflon parts? Solve Friction, Chemical & Electrical Challenges

- What causes a PTFE butterfly valve to leak? Diagnose and Prevent Seal Failure

- What technological advancements have been made in PTFE lined check valves? Boost Efficiency & Reliability