PTFE washers provide electrical insulation by leveraging the material's inherent molecular structure, which creates exceptionally high electrical resistance and dielectric strength. This means Polytetrafluoroethylene (PTFE) not only stops the flow of current under normal conditions but can also withstand very high voltages without breaking down, preventing dangerous electrical shorts and leakage.

The core reason PTFE is trusted for electrical insulation is not just its ability to block current, but its unwavering performance across a vast range of temperatures, frequencies, and chemical environments, ensuring reliable protection for sensitive components where other materials would fail.

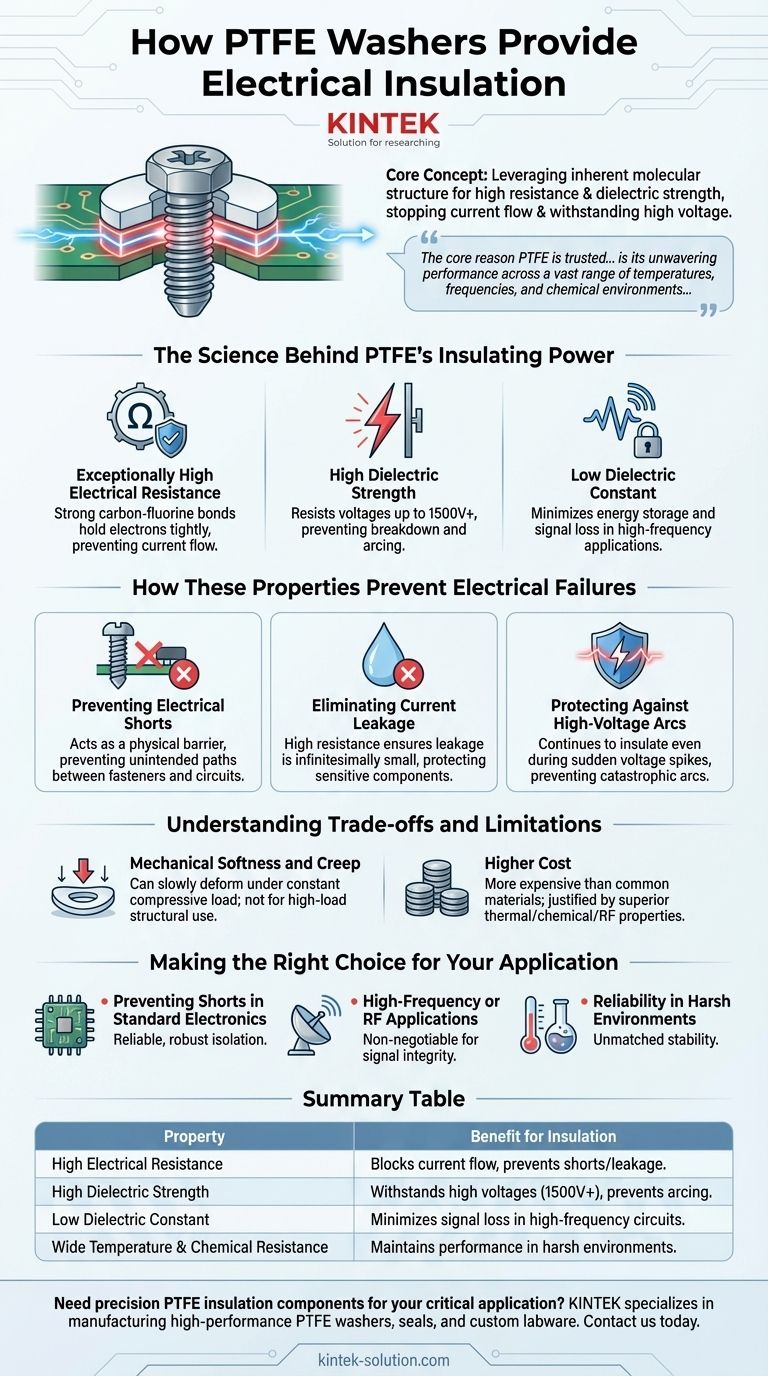

The Science Behind PTFE's Insulating Power

To understand why PTFE is such a superior insulator, we must look at its specific electrical properties. These characteristics work together to create a robust barrier against electrical flow and interference.

Exceptionally High Electrical Resistance

Electrical resistance is a measure of how strongly a material opposes the flow of electric current. PTFE possesses an extremely high volume resistivity.

This property is due to its stable molecular structure, built on strong carbon-fluorine bonds, which hold electrons tightly and prevent them from moving freely to conduct electricity.

High Dielectric Strength

Dielectric strength measures a material's ability to act as an insulator under high electrical stress. It defines the maximum voltage a material can withstand before it breaks down and allows current to pass through.

PTFE has a very high dielectric strength, capable of resisting voltages up to 1500 volts or more depending on thickness. This makes it ideal for preventing high-voltage arcing between components.

Low Dielectric Constant

The dielectric constant indicates how much electrical energy a material can store in an electric field. Materials with a low dielectric constant are poor at storing energy.

This is a critical advantage in high-frequency applications, as it minimizes interference (crosstalk) and prevents signal loss in sensitive circuits, preserving the integrity of data and communications.

How These Properties Prevent Electrical Failures

The theoretical properties of PTFE translate directly into practical benefits that ensure the safety and efficiency of electronic systems.

Preventing Electrical Shorts

The most common use of a PTFE washer is to act as a physical and electrical barrier.

When placed between a metal screw and a circuit board or chassis, its high resistance prevents the fastener from creating an unintended electrical path, which would cause a short circuit and damage components.

Eliminating Current Leakage

In any electrical system, some minimal current can "leak" through an insulator.

PTFE's high resistance ensures this leakage is infinitesimally small, protecting sensitive components from stray currents and improving the overall efficiency of the device.

Protecting Against High-Voltage Arcs

The material's high dielectric strength is a critical safety feature.

It ensures that even if a sudden voltage spike occurs, the washer will not fail. It will continue to insulate, preventing a catastrophic arc that could destroy the circuitry.

Understanding the Trade-offs and Limitations

While an excellent insulator, PTFE is not the solution for every engineering problem. Understanding its limitations is key to using it effectively.

Mechanical Softness and Creep

PTFE is a relatively soft material. Under a constant compressive load, such as a tightened bolt, it can slowly deform over time in a process known as "creep."

This means it is not suitable for high-load structural applications where maintaining precise dimensions under pressure is critical.

Higher Cost

Compared to other common insulating materials like nylon or certain types of rubber, PTFE is generally more expensive.

Its use is best justified in applications where its superior thermal, chemical, or high-frequency insulating properties are truly necessary.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the specific demands of your project.

- If your primary focus is preventing shorts in standard electronics: PTFE offers an extremely reliable and robust solution for isolating fasteners and components from conductive surfaces.

- If your primary focus is high-frequency or RF applications: PTFE's low dielectric constant is a non-negotiable feature for maintaining signal integrity and minimizing interference.

- If your primary focus is reliability in harsh environments: PTFE's unmatched chemical and thermal stability ensures its insulating properties will not degrade when exposed to extreme conditions.

Ultimately, choosing PTFE is a decision for uncompromising electrical stability in demanding applications.

Summary Table:

| Property | Benefit for Insulation |

|---|---|

| High Electrical Resistance | Blocks current flow, prevents shorts and leakage. |

| High Dielectric Strength | Withstands high voltages (e.g., 1500V+), prevents arcing. |

| Low Dielectric Constant | Minimizes signal loss and interference in high-frequency circuits. |

| Wide Temperature & Chemical Resistance | Maintains performance in harsh environments where other materials fail. |

Need precision PTFE insulation components for your critical application?

KINTEK specializes in manufacturing high-performance PTFE washers, seals, and custom labware for the semiconductor, medical, and industrial sectors. Our components are engineered for superior dielectric strength and reliability in extreme conditions.

Contact us today to discuss your custom fabrication needs—from prototypes to high-volume orders—and ensure your equipment operates with uncompromising safety and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support