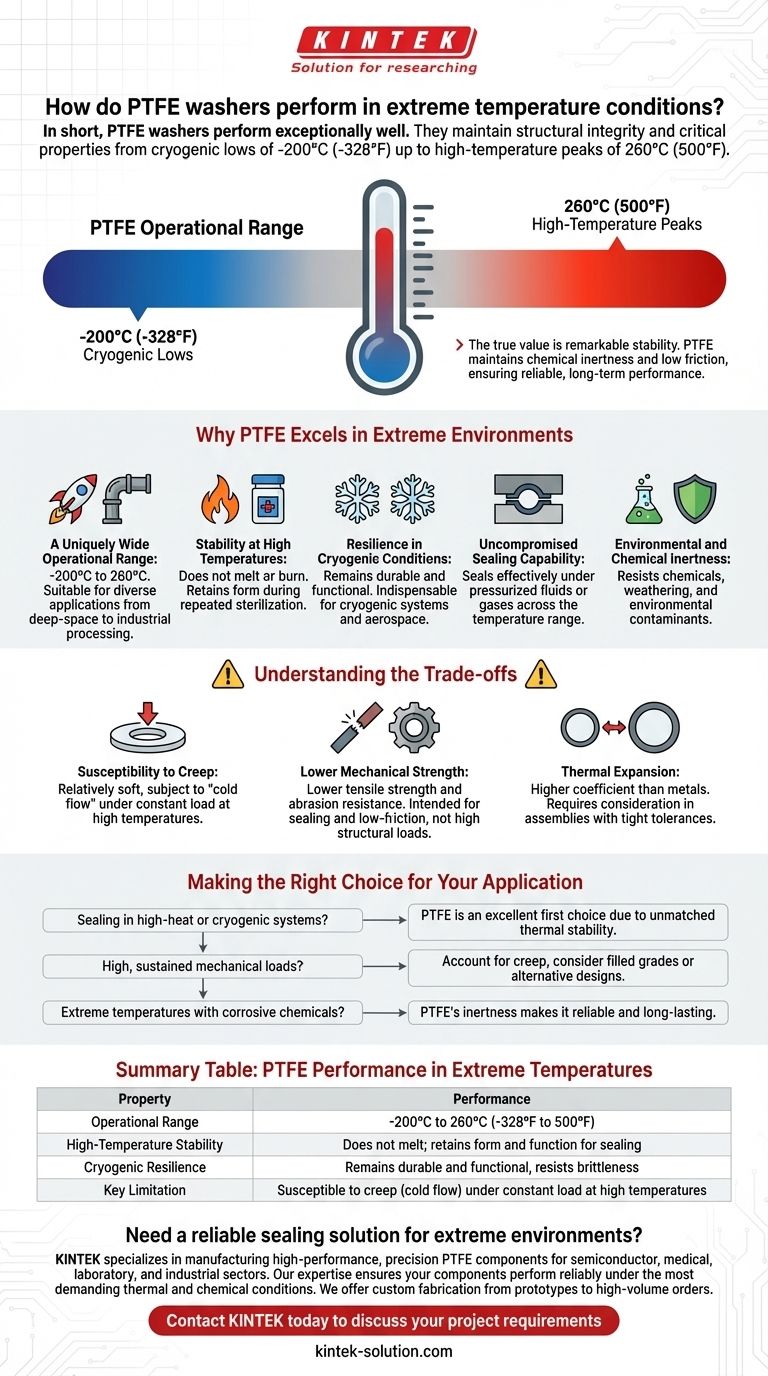

In short, PTFE washers perform exceptionally well in extreme temperatures. They maintain their structural integrity and critical properties across a vast operational range, typically from cryogenic lows of -200°C (-328°F) up to high-temperature peaks of 260°C (500°F). This makes them a default choice for applications where other materials would quickly fail.

The true value of PTFE in extreme temperatures isn't just its wide operating range, but its remarkable stability. Unlike many materials that become brittle in the cold or degrade in the heat, PTFE maintains its crucial properties—like chemical inertness and low friction—ensuring reliable, long-term performance.

Why PTFE Excels in Extreme Environments

To understand PTFE's performance, we must look beyond the numbers and at the inherent qualities of the material itself. Its molecular structure gives it a unique combination of resilience and stability that is difficult to replicate.

A Uniquely Wide Operational Range

The most cited feature of PTFE is its ability to function reliably from -200°C to 260°C (-328°F to 500°F). This single characteristic makes it suitable for an incredible diversity of applications, from deep-space components to high-temperature industrial processing.

Stability at High Temperatures

At the upper end of its range, PTFE does not melt or burn. It retains its form and function, which is critical in applications like pharmaceutical production, where components must withstand repeated high-temperature sterilization without cracking or losing their sealing capability.

Resilience in Cryogenic Conditions

While many polymers become brittle and fracture at very low temperatures, PTFE remains durable and functional. This makes it indispensable for cryogenic systems and aerospace engineering, where components are exposed to the extreme cold of liquid gases or the vacuum of space.

Uncompromised Sealing Capability

A washer's primary job is often to create a seal. PTFE washers continue to effectively seal mating surfaces without leaking, even when subjected to pressurized fluids or gases across their entire temperature range. This reliability is a key reason for their widespread adoption.

Environmental and Chemical Inertness

Extreme temperature applications are often found in harsh environments. PTFE is almost universally resistant to chemicals and is unaffected by weathering or environmental contaminants, ensuring its properties do not degrade over a long service life.

Understanding the Trade-offs

No material is perfect for every situation. To use PTFE effectively, it's critical to be aware of its mechanical limitations, especially when temperature is a factor.

Susceptibility to Creep

PTFE is a relatively soft material. Under a constant compressive load, especially at elevated temperatures, it can be subject to "creep" or "cold flow," a slow, permanent deformation over time. This must be accounted for in the design of high-pressure joints.

Lower Mechanical Strength

Compared to metals or harder plastics, PTFE has lower tensile strength and abrasion resistance. It is not intended for high-load structural applications. Its strength lies in sealing, insulation, and providing a low-friction surface, not bearing significant mechanical stress.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than most metals. In assemblies with tight tolerances that undergo significant temperature swings, this difference in expansion and contraction rates must be factored into the design to prevent component failure.

Making the Right Choice for Your Application

Your final decision should be based on the primary demand of your specific use case.

- If your primary focus is sealing in high-heat or cryogenic systems: PTFE is an excellent first choice due to its unmatched thermal stability and consistent sealing properties.

- If your application involves high, sustained mechanical loads: You must account for PTFE's potential for creep, especially at the higher end of its temperature range, and may need to consider filled PTFE grades or alternative designs.

- If your environment combines extreme temperatures with corrosive chemicals: PTFE's profound chemical inertness makes it one of the most reliable and long-lasting materials available for these dual-challenge scenarios.

Ultimately, understanding both its exceptional thermal range and its mechanical limitations is the key to successfully leveraging PTFE in your most demanding applications.

Summary Table:

| Property | Performance in Extreme Temperatures |

|---|---|

| Operational Range | -200°C to 260°C (-328°F to 500°F) |

| High-Temperature Stability | Does not melt; retains form and function for sealing |

| Cryogenic Resilience | Remains durable and functional, resists brittleness |

| Key Limitation | Susceptible to creep (cold flow) under constant load at high temperatures |

Need a reliable sealing solution for extreme environments?

KINTEK specializes in manufacturing high-performance, precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components perform reliably under the most demanding thermal and chemical conditions.

We offer custom fabrication from prototypes to high-volume orders, tailoring solutions to your specific application challenges.

Contact KINTEK today to discuss your project requirements and discover how our PTFE expertise can benefit you.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability