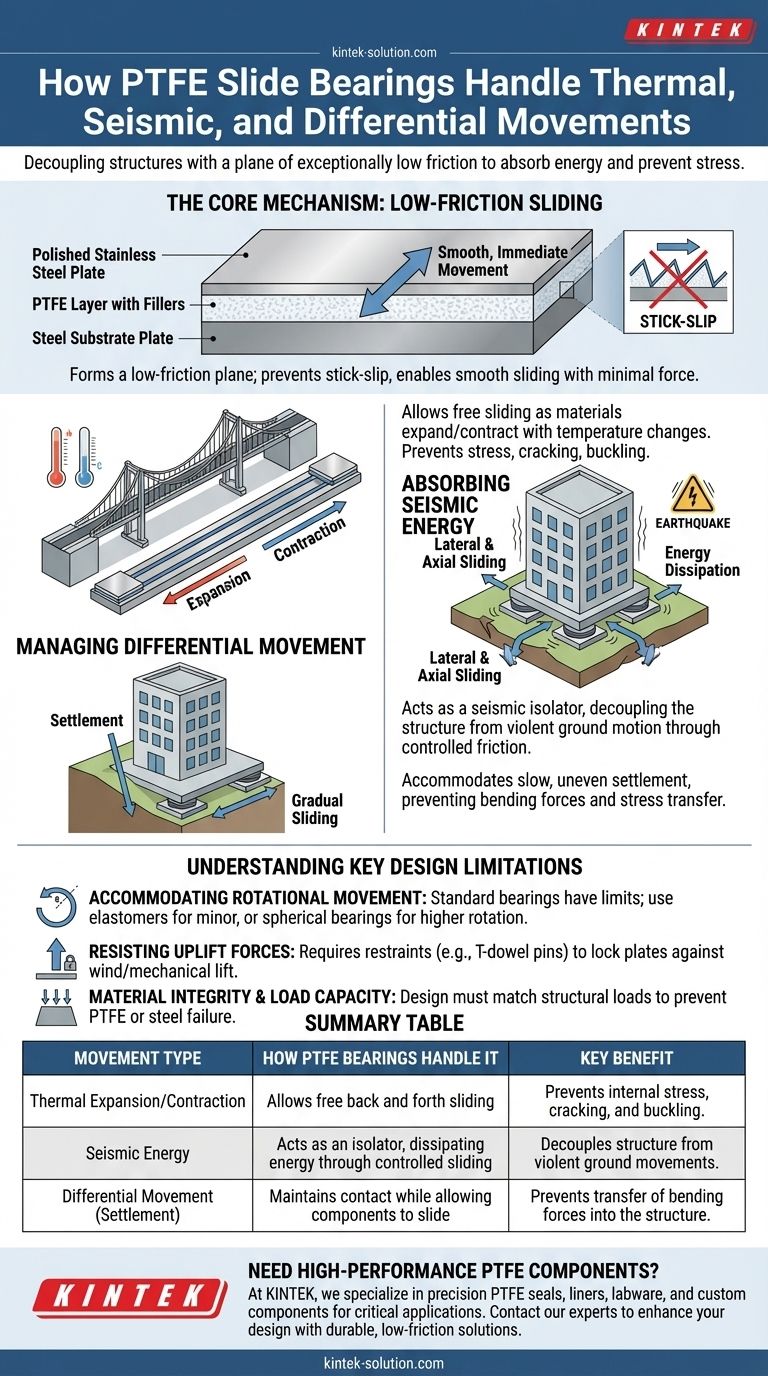

At its core, a PTFE slide bearing manages thermal, seismic, and differential movements by creating a plane of exceptionally low friction. This allows structural components to move independently and predictably, absorbing and dissipating energy from expansion, ground shifts, or settlement without transferring damaging stress into the structure itself.

The fundamental purpose of a PTFE slide bearing is to decouple a structure from its foundation or another element. By allowing controlled, low-resistance sliding, it transforms potentially destructive forces into manageable, predictable movements.

The Core Mechanism: Low-Friction Sliding

PTFE, or Polytetrafluoroethylene, is a unique material that forms the heart of these bearings. Understanding its function is key to understanding how the entire system protects a structure.

How PTFE Enables Movement

A typical PTFE sliding bearing consists of a PTFE layer (often with fillers for enhanced durability) on one steel plate sliding against a highly polished stainless steel surface on another. This pairing creates one of the lowest coefficients of friction of any solid material.

This key property prevents "stick-slip," a jerky motion where static friction builds up and releases suddenly. Instead, movement is smooth and immediate, requiring very little force to initiate.

Handling Thermal Expansion and Contraction

As ambient temperature changes, construction materials like steel and concrete expand and contract. Over the length of a bridge or a large roof, this movement can be substantial.

A PTFE bearing allows the structure to slide freely back and forth. This prevents the buildup of immense internal stresses that could otherwise cause cracking, buckling, or failure.

Absorbing Seismic Energy

During an earthquake, the ground moves violently in multiple directions. A structure built directly on its foundation would be forced to absorb all of that chaotic energy.

PTFE bearings act as a seismic isolator. They allow the structure to slide laterally and axially, effectively disconnecting it from the most intense ground vibrations and dissipating the seismic energy through controlled friction.

Managing Differential Movement

Differential movement, or settlement, occurs when different parts of a structure's foundation settle into the ground at different rates.

The bearing accommodates this slow, gradual movement by ensuring the components remain in continuous contact while allowing them to slide. This prevents the transfer of bending forces and stress into the building's frame.

Understanding Key Design Limitations

While highly effective, PTFE slide bearings are not a universal solution. Their performance depends on a design that accounts for specific load types and potential failure modes.

Accommodating Rotational Movement

Standard slide bearings are designed for translation (sliding) and only support vertical loads. They can accommodate fractions of a degree of rotation.

For minor misalignment, a thin layer of an elastomer like neoprene can be integrated. For higher rotation, a thicker elastomer or a dedicated spherical bearing assembly is required, though this can introduce other stability considerations.

Resisting Uplift Forces

Forces from heavy winds or certain mechanical systems can create an uplift load, attempting to pull the bearing apart. This can misalign or completely dislodge the components.

To counteract this, the design must include restraints. T-shaped dowel pins or brackets are common solutions that physically lock the plates together while still allowing them to slide freely within engineered slots.

Material Integrity and Load Capacity

The PTFE itself is bonded to a rigid steel substrate plate that distributes the load. The system is designed to handle immense vertical pressure, but the design must match the specific load requirements of the structure to prevent material failure.

Making the Right Choice for Your Goal

Properly specified PTFE bearings provide maintenance-free, durable performance for the life of a structure. Your design focus will determine the most critical considerations.

- If your primary focus is thermal management: Ensure the bearing's design allows for the maximum calculated expansion and contraction distance.

- If your primary focus is seismic isolation: Prioritize a design that allows sufficient lateral travel and includes robust restraints to handle uplift and prevent dislodging.

- If your structure will experience significant rotation or uplift: A standard PTFE slide bearing alone is insufficient; it must be engineered as part of a larger system with elastomeric or mechanical components.

By understanding these principles, you can effectively use PTFE bearings to create structures that are more resilient, durable, and safe.

Summary Table:

| Movement Type | How PTFE Bearings Handle It | Key Benefit |

|---|---|---|

| Thermal Expansion/Contraction | Allows structure to slide freely back and forth | Prevents internal stress, cracking, and buckling |

| Seismic Energy | Acts as an isolator, dissipating energy through controlled sliding | Decouples structure from violent ground movements |

| Differential Movement (Settlement) | Maintains contact while allowing components to slide | Prevents transfer of bending forces into the structure |

Need high-performance PTFE components for your critical applications?

At KINTEK, we specialize in the precision manufacturing of PTFE seals, liners, labware, and custom components. Our expertise in material science and custom fabrication ensures your project—from prototypes to high-volume orders—benefits from durable, low-friction solutions that handle extreme conditions.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our components are engineered for resilience and reliability.

Contact our experts today to discuss how KINTEK's PTFE solutions can enhance your structural or equipment design.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments