When it comes to chemical compatibility, PTFE O-rings stand in a class of their own. They are functionally inert against nearly all industrial chemicals and solvents. This includes aggressive substances like strong acids, alkalis, corrosive cleaning agents, and various organic compounds, making them a default choice for the most demanding sealing environments.

The core consideration is not if a PTFE O-ring can resist your chemical environment—it almost certainly can. The critical question is whether its unique mechanical properties, particularly its relative rigidity compared to rubber elastomers, are the right fit for your specific sealing application.

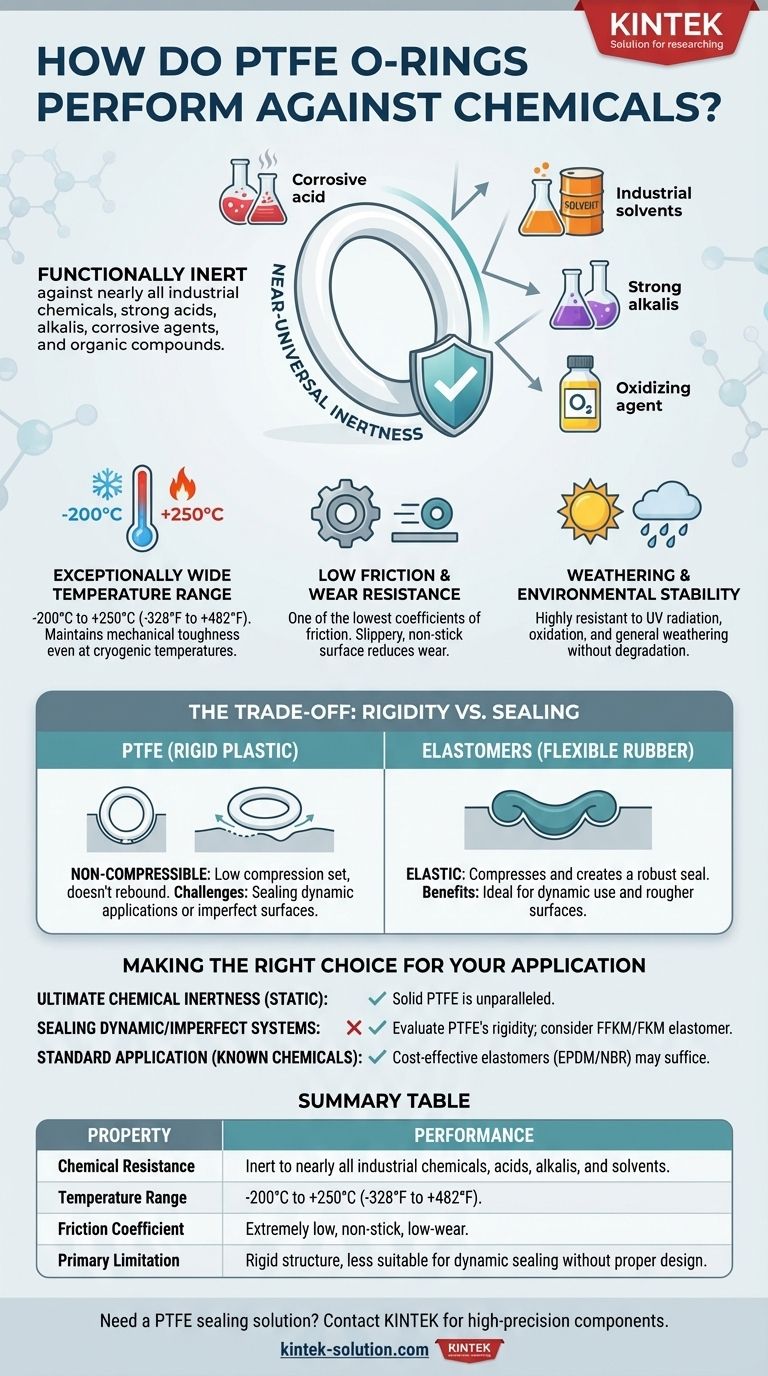

The Foundation of PTFE's Chemical Resistance

Polytetrafluoroethylene (PTFE) is a fluoropolymer with an exceptionally stable molecular structure. This stability is the source of its remarkable and near-universal chemical inertness, which is its defining characteristic.

Near-Universal Inertness

PTFE simply does not react with the vast majority of substances. It reliably resists damage and degradation from strong acids, bases, alcohols, and complex organic solvents. This makes it an invaluable material in chemical processing, pharmaceuticals, and laboratory equipment where purity and longevity are paramount.

Stability in Aggressive Environments

This resistance extends to highly reactive and oxidizing agents. PTFE is stable when exposed to substances like chlorine dioxide, pure oxygen, and other aggressive chemicals often used for cleaning and disinfection. Where other materials would quickly degrade, PTFE maintains its structural integrity.

Beyond Chemicals: Key Performance Characteristics

While chemical resistance is its primary benefit, PTFE's other properties are crucial for determining its suitability for a given application. It offers a combination of attributes that few other materials can match.

An Exceptionally Wide Temperature Range

PTFE O-rings perform reliably across a vast temperature spectrum, typically cited from -200°C to +250°C (-328°F to +482°F). It maintains good mechanical toughness even at cryogenic temperatures. While some materials like FFKM can exceed its upper limit, they cannot match PTFE's performance at extreme low temperatures.

Low Friction and Wear Resistance

PTFE has one of the lowest coefficients of friction of any solid material, giving it a slippery, non-stick surface. This inherent lubricity reduces wear and abrasion in applications with moving parts, contributing to a longer service life.

Weathering and Environmental Stability

The material is highly resistant to degradation from UV radiation, oxidation, and general weathering. This makes it suitable for long-term outdoor applications or any environment where it will be exposed to the elements without risk of embrittlement or breakdown.

Understanding the Trade-offs: Rigidity and Sealing

The primary limitation of solid PTFE O-rings is not chemical but mechanical. Unlike common elastomers like Nitrile (NBR) or Viton™ (FKM), PTFE is a relatively rigid plastic, not a flexible rubber.

The Challenge of "Non-Compressibility"

A standard O-ring works by being compressed into a groove, where its elastic "spring-back" force creates a seal. Because PTFE is stiff, it does not compress and rebound in the same way. This means it may not conform as well to surface imperfections in a flange or fitting, potentially compromising the seal.

Low Compression Set

PTFE exhibits a low compression set, which means it resists being permanently deformed after a compressive force is removed. While this is a positive trait, it stems from its inherent rigidity. It doesn't deform easily in the first place, which is the very property that can make sealing a challenge.

When an Elastomer is a Better Fit

For dynamic applications (involving movement) or in hardware with rougher surface finishes, a true elastomer is often a better choice. Materials like FKM offer excellent chemical resistance to many substances and provide the flexibility needed to maintain a robust seal under varying conditions. The ultimate choice always depends on a complete analysis of the chemicals, temperatures, and mechanical forces involved.

Making the Right Choice for Your Application

Selecting the correct O-ring requires balancing chemical compatibility with the physical demands of the system. Use these guidelines to make an informed decision.

- If your primary focus is ultimate chemical inertness in a static application: Solid PTFE is an unparalleled choice, offering the widest resistance across an extreme temperature range.

- If your primary focus is sealing in a dynamic system or with imperfect surfaces: You must evaluate if PTFE's rigidity can provide a sufficient seal, or if a high-performance elastomer like FFKM or FKM is a necessary trade-off.

- If your primary focus is a standard application with known, less aggressive chemicals: More common and cost-effective elastomers like EPDM or NBR may provide all the performance you need without the specific trade-offs of PTFE.

Understanding both its unparalleled chemical resistance and its unique mechanical properties is the key to successfully deploying PTFE as a sealing solution.

Summary Table:

| Property | Performance |

|---|---|

| Chemical Resistance | Inert to nearly all industrial chemicals, acids, alkalis, and solvents |

| Temperature Range | -200°C to +250°C (-328°F to +482°F) |

| Friction Coefficient | Extremely low, providing non-stick and low-wear properties |

| Primary Limitation | Rigid structure, less suitable for dynamic sealing without proper design |

Need a PTFE sealing solution that withstands your toughest chemical environment?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including O-rings, seals, liners, and custom labware. Our expertise ensures that your sealing applications in semiconductor, medical, laboratory, and industrial settings achieve maximum reliability and longevity.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific requirements.

Contact us today to discuss how our PTFE solutions can solve your chemical resistance challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications