When comparing PTFE vs. Teflon O-rings, the critical thing to understand is that they are the same material. "Teflon" is simply the well-known trade name for Polytetrafluoroethylene (PTFE), a fluoropolymer material originally developed by DuPont and now produced by Chemours. Any O-ring sold as "Teflon" is made of PTFE, meaning they share the exact same chemical composition, physical properties, and performance characteristics.

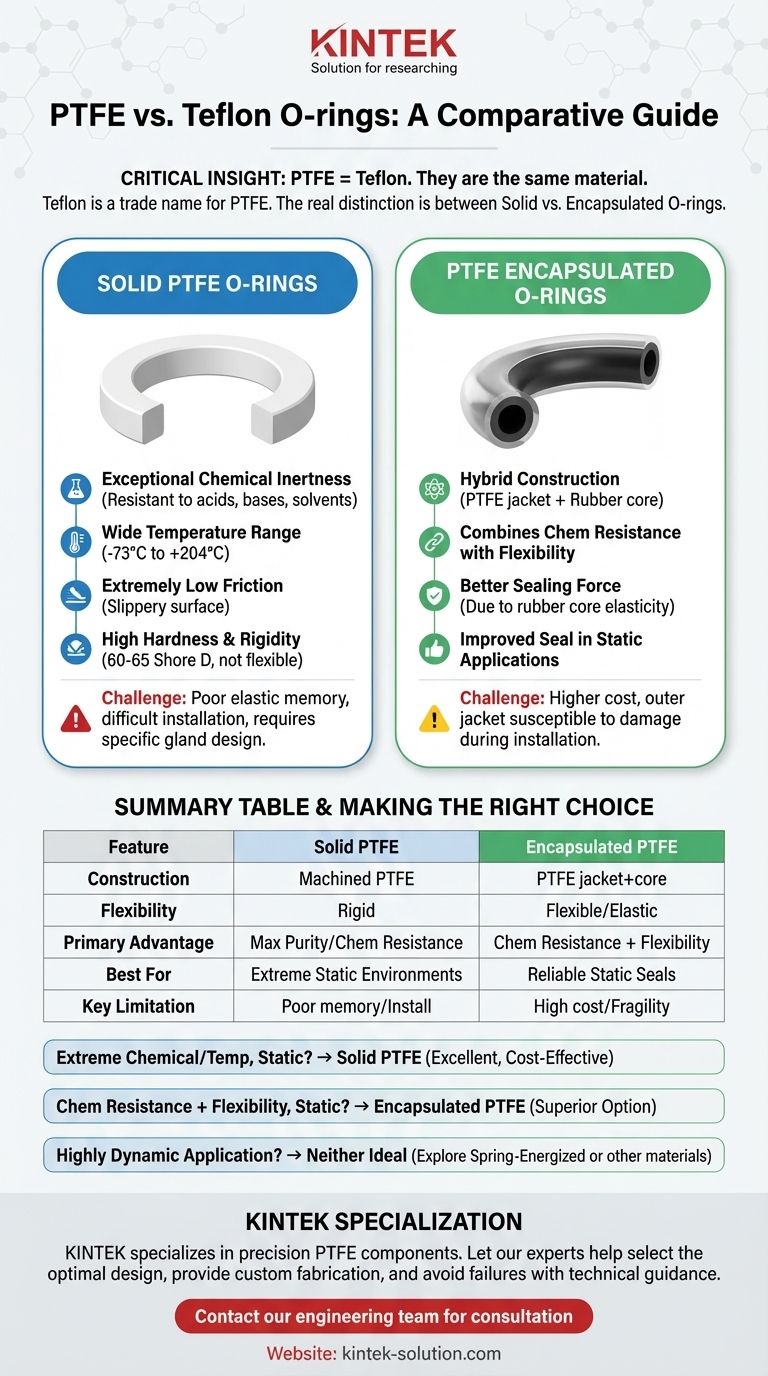

The real distinction you need to make is not between PTFE and Teflon, but between solid PTFE O-rings and PTFE encapsulated O-rings. Solid PTFE offers unmatched chemical resistance but is very rigid, while encapsulated versions add flexibility by combining a PTFE shell with a rubber core.

Understanding the Core Material: PTFE

What is PTFE?

Polytetrafluoroethylene (PTFE) is a high-performance synthetic fluoropolymer. Its unique properties make it an invaluable material for demanding sealing applications where other materials would quickly fail.

The name Teflon is the brand, while PTFE is the generic material name. They are used interchangeably in the industry.

Key Properties of Solid PTFE O-rings

Solid PTFE O-rings are machined from pure PTFE stock and are known for a distinct set of characteristics.

- Exceptional Chemical Inertness: They are resistant to nearly all industrial chemicals, including aggressive acids, bases, and solvents.

- Wide Temperature Range: PTFE performs reliably across a very broad temperature spectrum, typically from -73°C to 204°C (-100°F to +400°F).

- Extremely Low Friction: Its surface is famously slippery, resulting in a very low coefficient of friction, which reduces wear in certain applications.

- High Hardness and Rigidity: With a durometer of 60-65 Shore D, PTFE is a hard plastic, not a flexible rubber.

The Critical Distinction: Solid vs. Encapsulated O-rings

The most important decision when considering PTFE for a seal is whether to use a solid ring or an encapsulated one.

Solid PTFE O-rings

These are monolithic rings made entirely of PTFE. They are the go-to choice when the primary concern is surviving extreme chemical exposure or high temperatures in a static (non-moving) application.

Their main advantage is their purity and direct exposure of the highly resistant PTFE material.

PTFE Encapsulated O-rings

This design features a core made of a flexible elastomer, such as FKM (Viton®) or Silicone, which is enclosed in a thin, seamless jacket of PTFE.

This hybrid construction provides the chemical resistance of a PTFE surface combined with the flexibility and elasticity of a rubber core, allowing for a much better seal in applications where the rigidity of solid PTFE would be a problem.

Understanding the Trade-offs and Application Challenges

While powerful, PTFE has significant limitations that must be factored into your design. Choosing incorrectly can easily lead to seal failure.

The Rigidity Problem

Solid PTFE O-rings have poor elastic memory. Unlike rubber, they do not spring back to their original shape after being compressed.

This lack of "bounce back" makes them unsuitable for most dynamic applications and can lead to leaks if the hardware shifts or experiences thermal cycling.

Installation and Gland Design

Because solid PTFE rings do not stretch, they can be difficult to install, especially in internal glands. They often require split-gland designs or specialized installation procedures.

Furthermore, the gland (the groove the O-ring sits in) must be designed for less "squeeze" than a standard rubber O-ring to avoid overstressing the material.

The Cost and Fragility of Encapsulated Rings

Encapsulated O-rings are a significant improvement for flexibility but come with their own trade-offs. They are considerably more expensive than both solid PTFE and standard elastomer O-rings.

The thin PTFE jacket is also susceptible to scratching or damage during installation. Any breach in this outer layer will expose the less-resistant inner core, completely compromising the seal.

Making the Right Choice for Your Application

Your choice depends entirely on the mechanical requirements of your sealing environment.

- If your primary focus is extreme chemical resistance in a static face seal: A solid PTFE O-ring is an excellent, cost-effective choice, provided your gland is designed for its rigidity.

- If you need chemical resistance plus better flexibility for a reliable static seal: An encapsulated O-ring is the superior option, as its rubber core provides the necessary sealing force that solid PTFE lacks.

- If your application is highly dynamic (e.g., rotating or reciprocating): Neither solid nor encapsulated PTFE O-rings are typically ideal; you should investigate spring-energized PTFE seals or other high-performance elastomers.

Understanding that the real choice is between solid and encapsulated designs allows you to select a seal based on mechanical needs, not brand names.

Summary Table:

| Feature | Solid PTFE O-rings | PTFE Encapsulated O-rings |

|---|---|---|

| Construction | Machined from pure PTFE | PTFE jacket with an elastomer core (e.g., FKM, Silicone) |

| Flexibility | Rigid (60-65 Shore D) | Flexible and elastic |

| Primary Advantage | Maximum chemical resistance and purity | Combines PTFE's chemical resistance with rubber's flexibility |

| Best For | Static face seals in extreme chemical/temperature environments | Static seals requiring a reliable, flexible seal |

| Key Limitation | Poor elastic memory; difficult installation | Higher cost; outer jacket can be damaged during installation |

Still Unsure Which PTFE O-ring is Right for Your Project?

Choosing between a solid PTFE and a PTFE encapsulated O-ring is critical for performance and safety. The wrong choice can lead to leaks and seal failure.

KINTEK specializes in manufacturing precision PTFE components, including seals, liners, and labware, for the most demanding industries. We understand the nuances of material selection and gland design. Our experts can help you:

- Select the optimal seal design (solid or encapsulated) based on your chemical, temperature, and mechanical requirements.

- Provide custom fabrication from prototypes to high-volume orders to ensure a perfect fit and function.

- Avoid costly failures with technical guidance on proper installation and gland design.

Let us provide the right seal for your critical application. Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support