To be direct, Polytetrafluoroethylene (PTFE) liners enhance the lifespan of medical devices by creating an exceptionally resilient barrier against the three primary causes of failure: mechanical wear, chemical degradation, and damage from sterilization. The material's uniquely low friction coefficient prevents wear on moving parts, while its chemical inertness and high-temperature stability protect the underlying device from corrosive bodily fluids and harsh cleaning protocols.

The core reason PTFE is so effective is that it isolates the functional components of a medical device from their hostile operating environment. This isolation dramatically reduces wear and tear, prevents material breakdown, and ensures the device can withstand repeated sterilization cycles, leading to a longer, more reliable service life.

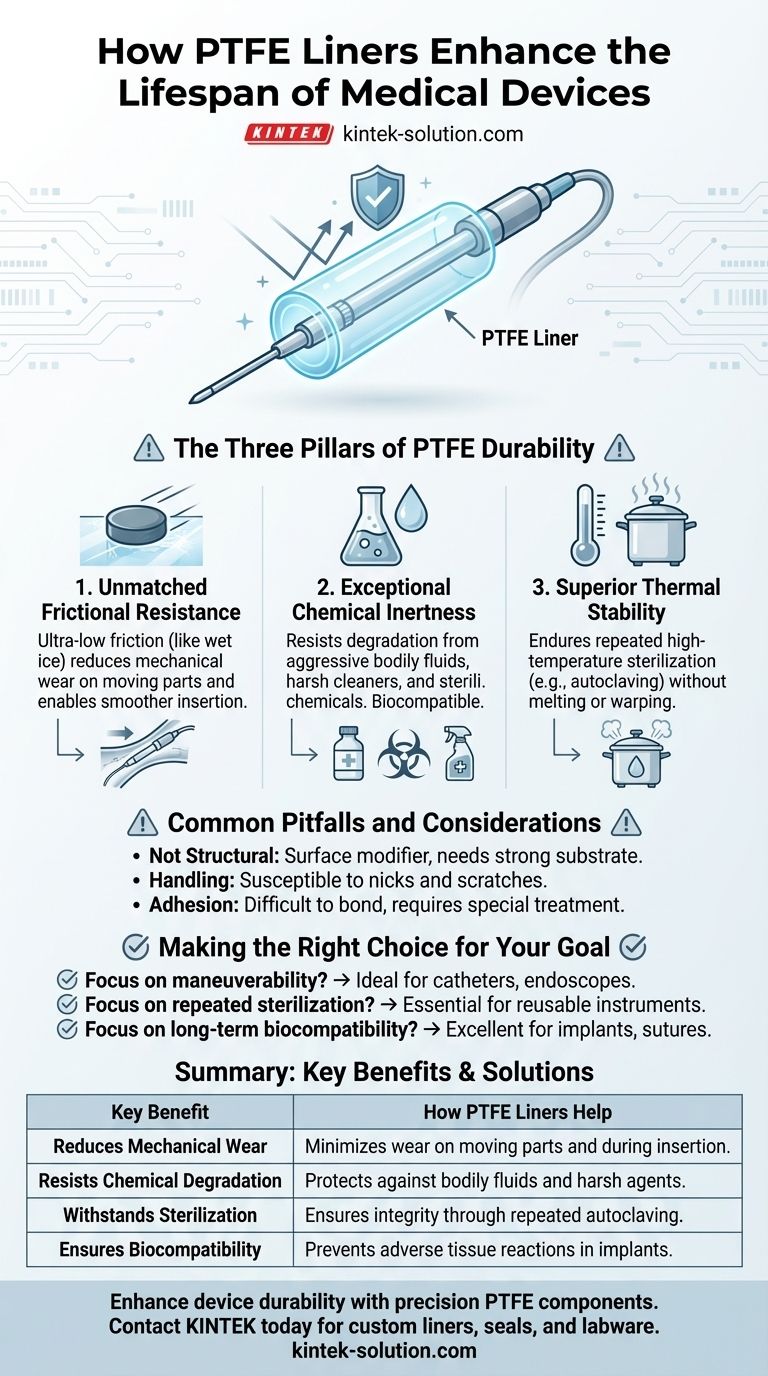

The Three Pillars of PTFE Durability

To truly understand how PTFE extends device longevity, we must look at its three fundamental properties. These characteristics work in concert to protect the integrity of the instrument or implant.

Pillar 1: Unmatched Frictional Resistance

PTFE has one of the lowest coefficients of friction of any solid material, a property often compared to wet ice on wet ice.

This ultra-low friction, or lubricity, is critical for reducing the mechanical wear and tear that shortens the life of devices with moving parts or those that navigate through bodily tissues.

This property is essential in applications like catheters and endoscopes, where it allows for smoother, less traumatic insertion and protects the internal components from abrasion during use.

Pillar 2: Exceptional Chemical Inertness

PTFE is virtually inert, meaning it does not react with the vast majority of chemicals.

This makes it highly resistant to degradation from aggressive bodily fluids, harsh cleaning agents, and the chemicals used in sterilization processes.

Because it is also highly biocompatible and hypoallergenic, it does not cause adverse tissue reactions, making it a superior material for implants, surgical sutures, and any device with prolonged patient contact.

Pillar 3: Superior Thermal Stability

Medical devices, particularly reusable ones, must endure repeated, high-temperature sterilization cycles, such as autoclaving.

PTFE maintains its structural integrity and key properties across a wide range of temperatures. It will not melt, warp, or degrade under standard sterilization conditions that would destroy lesser polymers.

This thermal stability ensures that a device lined with PTFE can be reliably sterilized and reused many times without compromising its performance or safety, directly extending its useful lifespan.

Common Pitfalls and Considerations

While PTFE is a superior material, its application is not without trade-offs. Acknowledging these limitations is key to successful implementation.

Not a Structural Material

PTFE is a relatively soft polymer. Liners are intended to be surface-modifying components, not the primary structural element of a device. They provide the critical surface properties, but the device itself must have its own mechanical strength.

Handling and Installation

Because it is a softer material, PTFE can be susceptible to nicks, scratches, or other mechanical damage if not handled or installed with care. Proper manufacturing and assembly protocols are essential to ensure the liner's integrity is not compromised.

Adhesion Challenges

The same non-stick properties that make PTFE so valuable also make it notoriously difficult to bond to other materials. Attaching a PTFE liner to a device substrate often requires specialized surface treatments or proprietary manufacturing techniques.

Making the Right Choice for Your Goal

Selecting the right material is a critical design decision. Use these points as a guide for when to specify a PTFE liner.

- If your primary focus is maneuverability and low friction: PTFE is the industry standard for catheters, guidewires, and endoscopes where reducing surface friction is paramount for performance and patient comfort.

- If your primary focus is durability through repeated sterilization: For reusable surgical instruments, PTFE's chemical and thermal resistance ensures the device withstands harsh cleaning protocols without degrading over time.

- If your primary focus is long-term biocompatibility: For implants, sutures, or cardiovascular components, PTFE's inert nature minimizes tissue reaction, making it an excellent choice for applications requiring direct and prolonged patient contact.

Ultimately, leveraging PTFE liners is a strategic engineering decision to build more reliable, safer, and cost-effective medical devices.

Summary Table:

| Key Benefit | How PTFE Liners Help |

|---|---|

| Reduces Mechanical Wear | Ultra-low friction coefficient minimizes wear on moving parts and during insertion. |

| Resists Chemical Degradation | Chemically inert properties protect against bodily fluids and harsh cleaning agents. |

| Withstands Sterilization | High thermal stability ensures integrity through repeated autoclaving and cleaning cycles. |

| Ensures Biocompatibility | Hypoallergenic and inert nature prevents adverse tissue reactions in implants. |

Ready to enhance the durability and reliability of your medical devices with precision-engineered PTFE components?

At KINTEK, we specialize in the custom fabrication of high-performance PTFE liners, seals, and labware for the medical, semiconductor, and laboratory industries. Our expertise ensures your devices benefit from the superior properties of PTFE—from prototypes to high-volume production.

Contact our experts today to discuss how our PTFE solutions can extend the lifespan of your critical medical devices.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications