In short, PTFE gaskets directly reduce industrial maintenance by lasting longer, simplifying the replacement process, and protecting the equipment they are installed in. Their inherent durability against chemicals and wear means they fail less often, while their non-stick, low-friction surface makes installation faster and reduces wear on expensive moving parts.

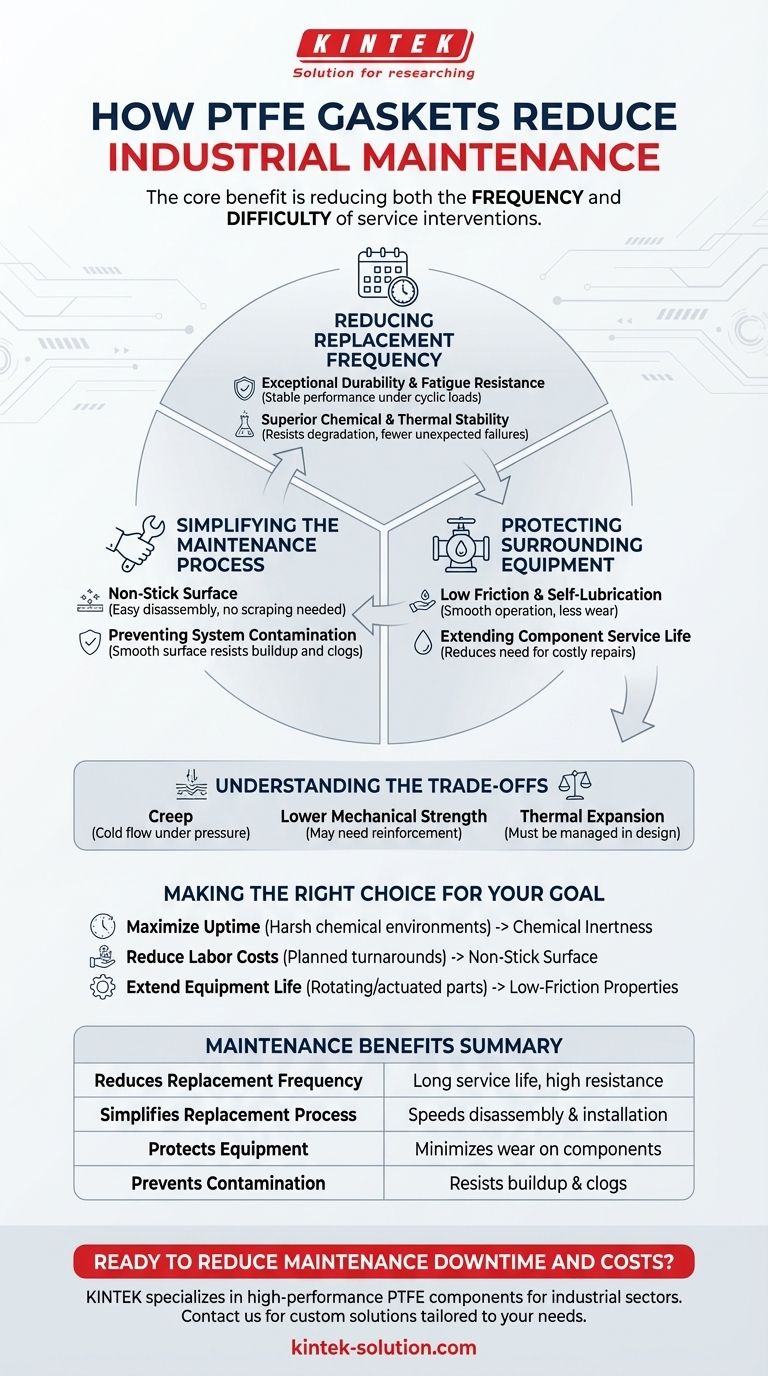

The core benefit of PTFE in a maintenance context is its ability to reduce both the frequency and the difficulty of service interventions. This translates directly to lower labor costs, increased operational uptime, and extended equipment lifespan.

The Core Principle: Reducing Replacement Frequency

The most significant maintenance saving comes from not having to perform the maintenance in the first place. PTFE's material properties are exceptionally suited to long service intervals.

Exceptional Durability and Fatigue Resistance

PTFE gaskets are engineered to withstand the stresses of industrial operations. They maintain stable performance even under long-term use and repeated cyclic loads.

This inherent toughness means they are less prone to failure from mechanical stress, a common issue with lesser materials.

Superior Chemical and Thermal Stability

One of PTFE's defining features is its near-total chemical inertness and wide temperature tolerance.

Unlike other materials that degrade when exposed to aggressive chemicals or temperature swings, PTFE remains stable. This stability means replacements are scheduled based on planned service intervals, not on unexpected material failure.

Simplifying the Maintenance Process Itself

When replacement is eventually necessary, PTFE gaskets make the job significantly easier and faster for maintenance teams.

The Non-Stick Surface Advantage

The non-stick nature of PTFE is a major advantage during disassembly. The gasket material does not adhere to flange faces or mating surfaces.

This prevents the time-consuming and potentially damaging process of scraping off old, baked-on gasket material, saving significant labor time during shutdowns.

Preventing System Contamination

Impurities and solid particles in the process media do not easily stick to PTFE's smooth surface.

This quality helps ensure the smooth operation of pipelines and equipment, preventing clogs or blockages that would otherwise require an unscheduled maintenance intervention.

Protecting Surrounding Equipment

A key, often overlooked benefit of PTFE is its ability to reduce wear and tear on the expensive equipment it serves.

Low Friction and Self-Lubrication

In dynamic applications like valves or pumps, PTFE's extremely low coefficient of friction allows components to operate smoothly.

Its self-lubricating properties minimize friction on moving parts like valve stems or shafts, reducing wear and eliminating the need for periodic lubrication—a maintenance task in itself.

Extending Component Service Life

By reducing friction and wear, PTFE gaskets and packing actively contribute to the longevity of the entire mechanical assembly.

This means fewer costly repairs or replacements of critical equipment components, shifting maintenance budgets away from reactive fixes and toward proactive improvements.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Susceptibility to Creep

Under sustained pressure and temperature, PTFE can be subject to "creep" or "cold flow," where the material slowly deforms over time. This must be accounted for in joint design and bolt torque procedures to prevent eventual leaks.

Lower Mechanical Strength

Compared to metallic gaskets, pure PTFE has lower compressive strength. For very high-pressure applications, reinforced PTFE (filled with materials like glass, carbon, or graphite) is often necessary to provide additional rigidity and creep resistance.

Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion. In systems with wide temperature fluctuations, this must be carefully managed through proper design to maintain a consistent seal.

Making the Right Choice for Your Goal

Select your gasket material based on the specific maintenance problem you are trying to solve.

- If your primary focus is maximizing uptime in harsh chemical environments: PTFE's chemical inertness is its greatest asset, ensuring fewer shutdowns for gasket failure.

- If your primary focus is reducing labor costs during planned turnarounds: The non-stick surface of PTFE flange gaskets drastically speeds up the replacement process.

- If your primary focus is extending the life of rotating or actuated equipment: The low-friction, self-lubricating properties of PTFE seals and packing will minimize wear on expensive components.

Ultimately, investing in PTFE gaskets is a strategic decision to reduce the long-term operational and financial burden of industrial maintenance.

Summary Table:

| Maintenance Benefit | How PTFE Gaskets Help |

|---|---|

| Reduces Replacement Frequency | Exceptional chemical, thermal, and fatigue resistance for long service life. |

| Simplifies Replacement Process | Non-stick surface prevents adhesion, speeding up disassembly and installation. |

| Protects Equipment | Low friction and self-lubrication minimize wear on valves, pumps, and other components. |

| Prevents Contamination | Smooth surface resists buildup, preventing clogs and unscheduled interventions. |

Ready to reduce your maintenance downtime and costs?

KINTEK specializes in manufacturing high-performance, precision PTFE components—including seals, gaskets, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services, from prototypes to high-volume orders, ensure you get a solution tailored to your specific operational challenges.

Contact KINTEK today to discuss how our PTFE components can enhance your equipment's reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications