To improve the inherent limitations of PTFE, the most common and effective method is compounding it with fillers. Materials like glass or carbon are added to the base PTFE to create a composite material that significantly enhances properties like wear resistance and mechanical strength, addressing its susceptibility to deformation under load.

The core challenge with Polytetrafluoroethylene (PTFE) is balancing its exceptional chemical resistance and low friction with its inherent mechanical weaknesses. While fillers can dramatically improve its wear and creep resistance, fundamental limitations like its thermal ceiling, fabrication difficulties, and specific chemical vulnerabilities must be managed through design or by selecting an alternative material.

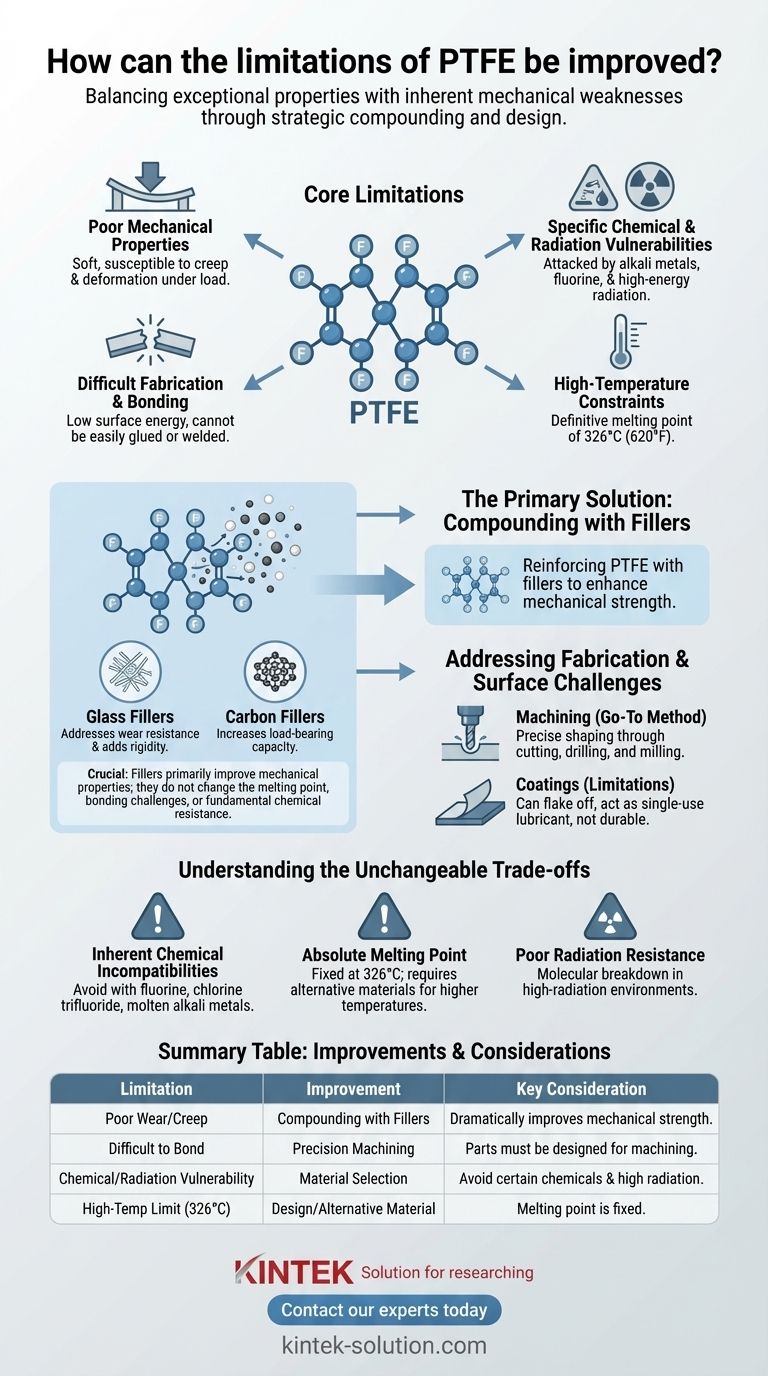

Understanding PTFE's Core Limitations

Before improving a material, we must first understand its weaknesses. While known for its non-stick surface and chemical inertness, PTFE has several well-defined constraints that impact its use in demanding applications.

Poor Mechanical Properties

PTFE is a relatively soft material. It is susceptible to creep (slow deformation under constant stress) and lacks sturdiness when placed under significant load pressure. This limits its use in high-load structural components.

Difficult Fabrication and Bonding

One of the most significant limitations is that PTFE cannot be easily glued or welded. Its extremely low surface energy, which makes it non-stick, also prevents adhesives from forming a strong bond.

Specific Chemical and Radiation Vulnerabilities

While chemically resistant to most substances, PTFE is not invincible. It can be attacked by highly reactive agents like certain alkali metals, fluorine gas, and powerful fluorinating agents at high temperatures and pressures. It also has poor resistance to high-energy radiation, which can break down its molecular structure.

High-Temperature Constraints

PTFE has a definitive melting point of 326°C (620°F). Above this temperature, it loses its structural integrity. This creates a hard limit for its use in very high-temperature environments.

The Primary Solution: Compounding with Fillers

The most successful strategy for overcoming PTFE's mechanical shortfalls is to reinforce it with fillers, creating what is known as "filled PTFE."

How Fillers Enhance Mechanical Strength

Fillers act as a reinforcing agent within the PTFE matrix. They provide a harder, more stable structure that helps the softer PTFE resist wear, reduce creep, and handle higher loads without deforming.

Common Fillers and Their Impact

The two most common fillers mentioned are glass and carbon. Adding these materials directly addresses wear resistance and adds rigidity. The specific filler and its percentage are chosen based on the desired final properties of the component.

What Fillers Cannot Fix

It is crucial to understand that fillers primarily improve mechanical properties. They do not increase PTFE's melting point, change its fundamental chemical resistance, or suddenly make it easy to glue or weld.

Addressing Fabrication and Surface Challenges

Because PTFE's surface properties are a core limitation for assembly, engineers must often design around them rather than change them.

Machining as the Go-To Method

Since bonding is not a viable option, PTFE is most often shaped through machining. It can be readily cut, drilled, and milled into precise final forms, especially when chilled to increase its rigidity.

The Problem with Coatings

One might assume a PTFE coating could solve problems, but these coatings have their own limitations. They can flake off, contaminating sensitive systems, and often have poor dynamic wear resistance, acting more as a single-use lubricant than a durable surface.

Understanding the Unchangeable Trade-offs

Building trust in a material requires acknowledging what cannot be changed. For PTFE, some limitations are inherent to its chemistry and must be accepted.

Inherent Chemical Incompatibilities

If your application involves elementary fluorine, chlorine trifluoride, or molten alkali metals, PTFE is simply not the right choice. No filler will prevent the chemical reaction that will occur.

The Absolute Melting Point

The 326°C melting point is a fixed property. If your operating temperature will exceed this, you must select a different high-performance polymer.

Poor Radiation Resistance

The molecular breakdown caused by high-energy radiation is a fundamental characteristic. In applications with significant radiation exposure, other materials should be considered.

Matching the PTFE Grade to Your Application

Choosing the correct material formulation is critical. Your decision should be guided by the primary challenge you need to overcome.

- If your primary focus is high wear and load-bearing capacity: Choose a filled PTFE with glass or carbon to provide the necessary mechanical strength.

- If your primary focus is creating complex, bonded assemblies: Recognize that PTFE cannot be glued; design parts to be machined from a solid block or mechanically fastened.

- If your primary focus is surviving extreme chemicals or radiation: Verify that your specific chemical agents are compatible with PTFE, and avoid it entirely in high-radiation environments.

Ultimately, successfully using PTFE is about leveraging its incredible strengths while strategically mitigating or designing around its known, unchangeable weaknesses.

Summary Table:

| Limitation | Primary Improvement Method | Key Considerations |

|---|---|---|

| Poor Wear/Creep Resistance | Compounding with Fillers (Glass, Carbon) | Dramatically improves mechanical strength and load capacity. |

| Difficult to Bond | Precision Machining | PTFE cannot be glued; parts must be designed for machining. |

| Specific Chemical/Radiation Vulnerability | Material Selection | Avoid use with certain alkali metals, fluorine, and in high-radiation environments. |

| High-Temperature Limit (326°C / 620°F) | Design/Alternative Material | The melting point is fixed; select a different polymer for higher temperatures. |

Need a High-Performance PTFE Component?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand how to select the right filled PTFE compound or fabrication method to overcome material limitations for your specific application, ensuring optimal performance and durability.

Let us help you leverage PTFE's strengths while mitigating its weaknesses.

Contact our experts today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability