In short, PTFE coated fasteners are highly beneficial in the automotive sector because they provide a unique combination of corrosion resistance, temperature stability, and an extremely low-friction surface. This makes them ideal for the harsh, demanding environments found in engines, exhaust systems, and brake assemblies, where they enhance longevity and dramatically simplify maintenance.

The core problem in automotive design is that fasteners are often subjected to extreme heat, corrosive fluids, and high torque. A PTFE coating acts as a protective shield, preventing common failures like seizing and rust while ensuring consistent, predictable performance.

Why Standard Fasteners Struggle in Automotive Environments

Traditional fasteners, even when plated with zinc or other materials, often fall short when exposed to the constant challenges of a vehicle's operating conditions. Understanding these failure points clarifies the value of a PTFE coating.

The Constant Threat of Corrosion

Fasteners on a vehicle's chassis, suspension, and brake systems are constantly exposed to water, road salt, and dirt. This environment creates a perfect recipe for rust, which can weaken the fastener and make removal nearly impossible.

The Problem of Seizing and Galling

In high-heat areas like an engine block or exhaust manifold, metal fasteners can expand and bond under pressure. This phenomenon, known as seizing or galling, effectively welds the nut to the bolt, complicating repairs and often requiring the fastener to be cut off.

Extreme Temperatures and Chemical Exposure

Components in the engine bay are subjected to a wide temperature range, from cold starts to operating temperatures exceeding 200°C. They are also exposed to corrosive automotive fluids like oil, fuel, and brake fluid, which can degrade lesser coatings.

The Core Advantages of a PTFE Coating

A Polytetrafluoroethylene (PTFE) coating is applied as a thin, uniform layer that fundamentally changes the fastener's surface properties. This addresses the core challenges of the automotive environment directly.

Unmatched Corrosion Resistance

The PTFE coating creates a non-porous, chemically inert barrier. This shield prevents moisture and corrosive agents like road salt from ever reaching the metal surface of the fastener, effectively stopping rust before it can start.

The Lowest Coefficient of Friction

PTFE has the lowest coefficient of friction of any known solid. This slick surface allows for smoother assembly and disassembly, preventing the microscopic tearing and welding that causes galling and seizing. It also ensures more consistent and accurate torque application.

Extreme Temperature Stability

PTFE coated fasteners can operate reliably across a vast temperature range, with a continuous working temperature up to +260°C. This makes them perfectly suited for high-heat applications like exhaust systems and engine components where other materials would fail.

Superior Chemical Inertness

The coating is highly resistant to virtually all automotive chemicals, including fuels, oils, solvents, and brake fluids. This ensures the fastener's protective layer remains intact throughout the vehicle's service life.

Understanding the Trade-offs

While highly effective, it's important to approach PTFE coated fasteners with a clear understanding of their characteristics. The benefits are primarily related to surface protection and performance, not the fastener's intrinsic strength.

Coating Durability is Key

The protection offered by PTFE is only as good as the coating itself. If the coating is scratched or chipped by a tool during installation, the underlying metal can be exposed, creating a potential point for corrosion to begin.

They Are Not a Structural Enhancement

A PTFE coating does not increase the tensile strength or shear strength of the base fastener. The mechanical properties are determined by the underlying steel, so selecting the correct grade of bolt for the application remains critical.

Cost vs. Lifecycle Value

Applying a high-quality PTFE coating is an additional manufacturing step, which increases the unit cost compared to a standard zinc-plated fastener. However, this initial investment is often offset by reduced labor costs during maintenance and increased component reliability.

How to Apply This to Your Project

Your choice should be guided by the specific demands of the automotive system you are working on.

- If your primary focus is longevity and corrosion prevention: PTFE is the superior choice for any fastener exposed to the elements, especially on chassis, suspension, and underbody components.

- If your primary focus is high-temperature performance: They are essential for engine bays, exhaust manifolds, and turbocharger assemblies where heat causes seizing.

- If your primary focus is ease of maintenance: Use these fasteners on components that require periodic disassembly, such as brake calipers, inspection covers, and service panels.

Ultimately, selecting PTFE coated fasteners is a strategic decision to invest in reliability, ensuring critical automotive systems perform safely and can be serviced efficiently for years to come.

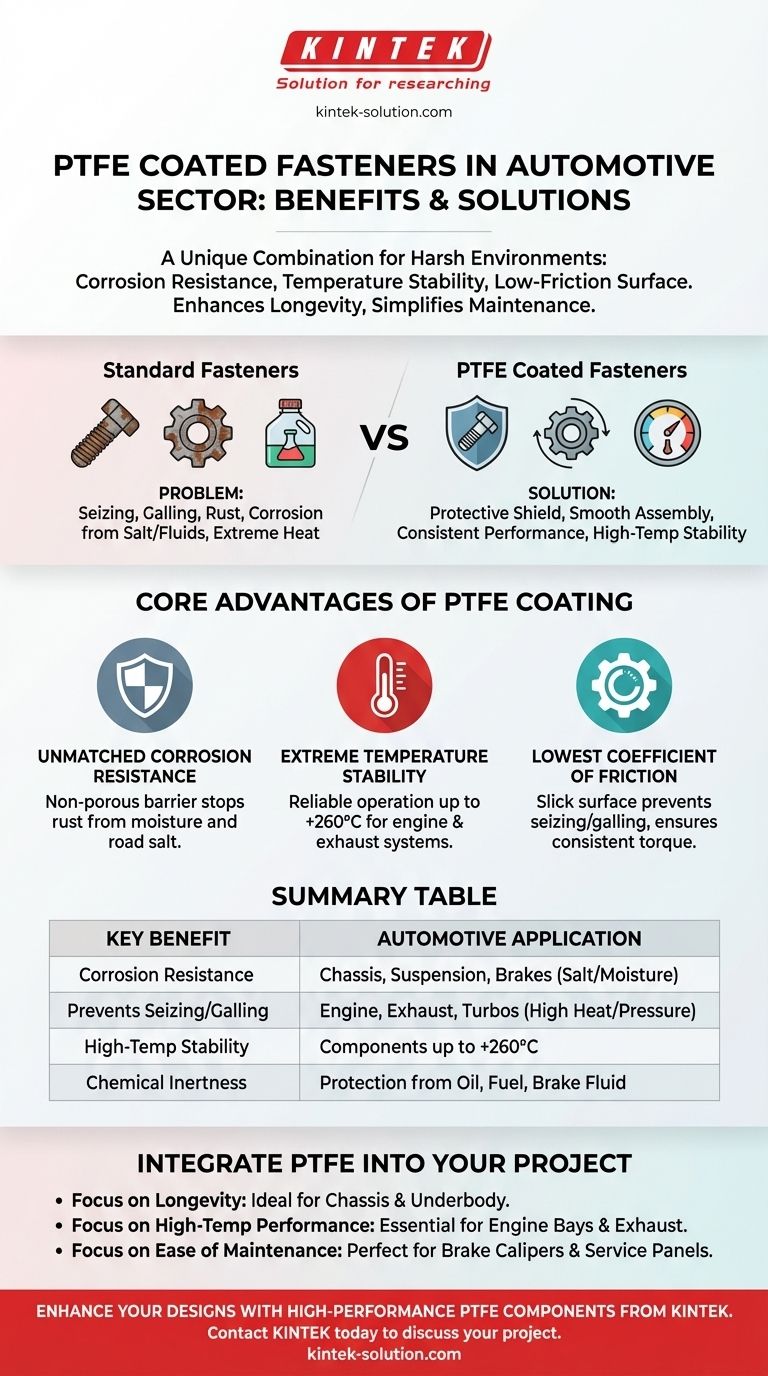

Summary Table:

| Key Benefit | Automotive Application |

|---|---|

| Corrosion Resistance | Chassis, suspension, brake systems exposed to road salt and moisture. |

| Prevents Seizing/Galling | Engine blocks, exhaust manifolds, turbochargers under high heat and pressure. |

| High-Temperature Stability | Components operating continuously up to +260°C. |

| Chemical Inertness | Protection from automotive fluids like oil, fuel, and brake fluid. |

Enhance your automotive designs with high-performance PTFE components from KINTEK.

Our precision-manufactured PTFE seals, liners, labware, and custom components are engineered to meet the demanding requirements of the automotive, semiconductor, medical, and industrial sectors. We specialize in custom fabrication, from prototypes to high-volume orders, ensuring your parts deliver unmatched corrosion resistance, temperature stability, and low friction.

Contact KINTEK today to discuss your project requirements and discover how our PTFE solutions can improve your product's reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications