In the pharmaceutical industry, PTFE components are foundational to ensuring product purity and safety. Primarily, PTFE is formed into balls, seals, and diaphragms for use in critical equipment like valves, pumps, and mixers. This widespread use is due to its unique combination of properties—extreme chemical inertness, high-temperature stability, and low friction—which are essential for handling sensitive compounds without contamination.

The core challenge in pharmaceutical manufacturing is preventing any interaction between equipment and the product itself. PTFE is the material of choice because its inherent non-reactivity and FDA-approved status provide a reliable guarantee of purity, from initial processing to final quality analysis.

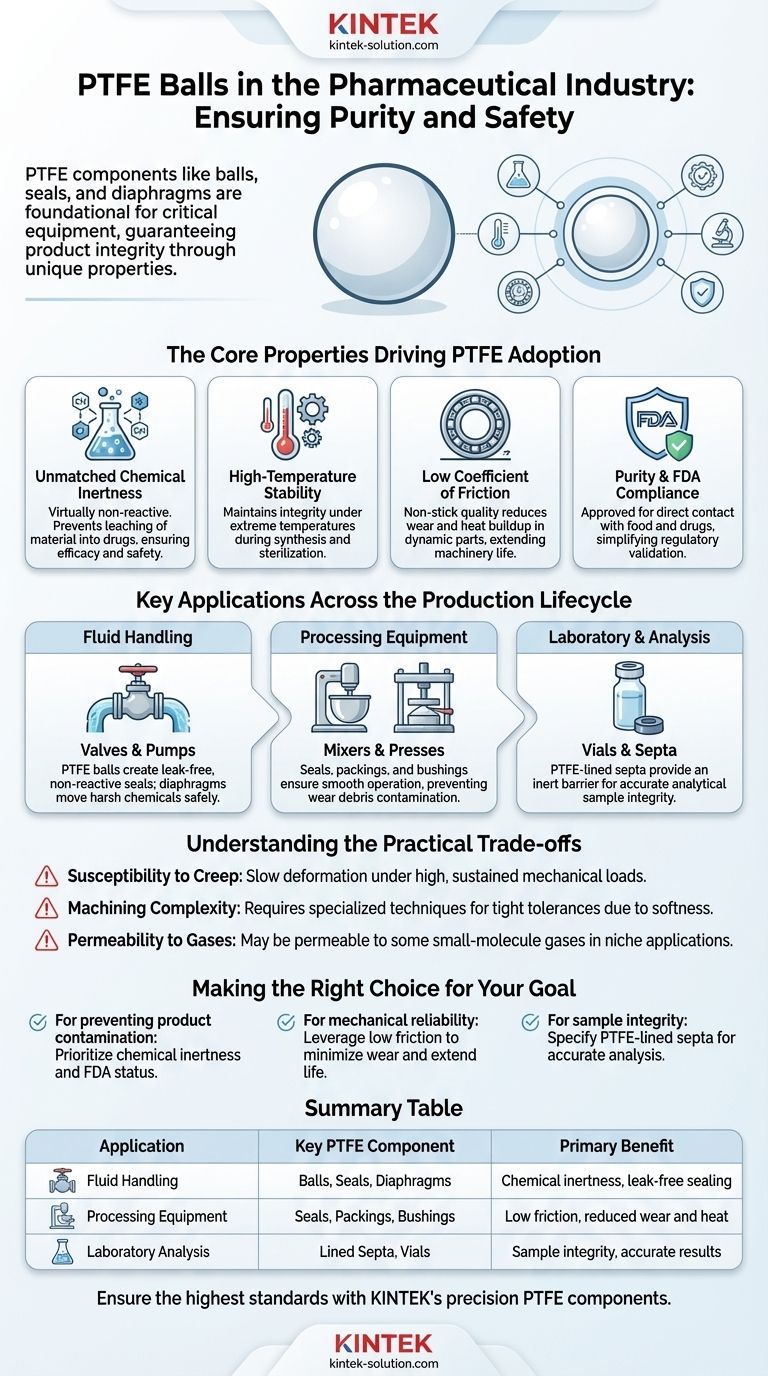

The Core Properties Driving PTFE Adoption

The selection of any material in a pharmaceutical context is a decision driven by safety, reliability, and regulatory compliance. PTFE excels across all three areas due to a few key characteristics.

Unmatched Chemical Inertness

PTFE is virtually non-reactive with the vast majority of chemicals, including aggressive solvents and strong oxidizers used in drug synthesis.

This inertness is critical because it prevents any material from leaching from the equipment into the drug product, which could alter its efficacy or safety.

High-Temperature Stability

Pharmaceutical processes often involve extreme temperatures for synthesis or sterilization.

PTFE components maintain their structural integrity and chemical properties under these conditions, ensuring consistent and reliable equipment performance.

Low Coefficient of Friction

Known commercially as Teflon, PTFE has one of the lowest coefficients of friction of any solid. This "non-stick" quality is vital in dynamic applications.

In pumps, presses, and valves, this property reduces wear and heat buildup, extending the life of the machinery and preventing damage to the product from excessive friction.

Purity and FDA Compliance

Crucially, PTFE is approved by the FDA for direct contact with food and drug products.

This pre-approved status simplifies the regulatory validation process for equipment manufacturers and pharmaceutical companies, making it a safe and efficient choice.

Key Applications Across the Production Lifecycle

PTFE's properties make it suitable for a wide range of applications, from large-scale manufacturing to precision laboratory work.

Fluid Handling: Valves and Pumps

This is the most common application for PTFE balls. They are used in check valves to create a perfect, non-reactive seal that controls the flow of sensitive liquids and gases.

PTFE is also used for diaphragms and seals in pumps, ensuring that harsh chemicals are moved without leaks or contamination.

Processing Equipment: Mixers and Presses

In mixers, presses, and other processing machinery, PTFE is used for seals, packings, and bushings.

These components ensure that moving parts operate smoothly while preventing lubricants or microscopic wear debris from entering the product stream.

Laboratory and Analysis: Vials and Septa

In quality control and research, PTFE-lined silicone septas are used to seal sample vials.

The PTFE layer provides a completely inert barrier, ensuring that the only reactions being measured are those within the sample itself, which is crucial for the accuracy and consistency of analytical results.

Understanding the Practical Trade-offs

While PTFE is an exceptional material, no single solution is perfect. A clear-eyed technical assessment requires acknowledging its limitations.

Susceptibility to Creep

PTFE is a relatively soft material. Under high, sustained mechanical loads, it can be prone to "creep," or slow deformation over time. This must be considered in high-pressure seal designs.

Machining Complexity

While it can be machined, PTFE's softness requires specialized techniques to achieve tight tolerances compared to metals. This can influence the cost and complexity of custom components.

Permeability to Certain Gases

Though an excellent barrier for liquids, PTFE can be permeable to some small-molecule gases. This is a niche concern but may be relevant in specific high-vacuum or specialized gas-handling applications.

Making the Right Choice for Your Goal

When specifying materials for pharmaceutical equipment, your primary objective dictates which of PTFE's properties is most critical.

- If your primary focus is preventing product contamination: Prioritize PTFE for its extreme chemical inertness and FDA-approved status, ensuring no material leaches into your product.

- If your primary focus is mechanical reliability in moving parts: Leverage PTFE's low friction in seals, bushings, and valve seats to minimize wear, reduce heat, and extend the service life of equipment.

- If your primary focus is sample integrity in lab analysis: Specify PTFE-lined septa and closures to guarantee that your analytical results are accurate and not skewed by container reactivity.

Ultimately, PTFE's unique combination of properties makes it an indispensable material for safeguarding purity and ensuring operational excellence in the demanding pharmaceutical environment.

Summary Table:

| Application | Key PTFE Component | Primary Benefit |

|---|---|---|

| Fluid Handling | Balls, Seals, Diaphragms | Chemical inertness, leak-free sealing |

| Processing Equipment | Seals, Packings, Bushings | Low friction, reduced wear and heat |

| Laboratory Analysis | Lined Septa, Vials | Sample integrity, accurate results |

Ensure the highest standards of purity and reliability in your pharmaceutical processes with KINTEK's precision PTFE components.

From PTFE balls for valves to custom seals and liners, we manufacture high-performance components that meet the stringent demands of the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get parts that guarantee chemical inertness, FDA compliance, and long-term performance.

Contact us today to discuss your specific needs and let our solutions enhance your product safety and operational efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions