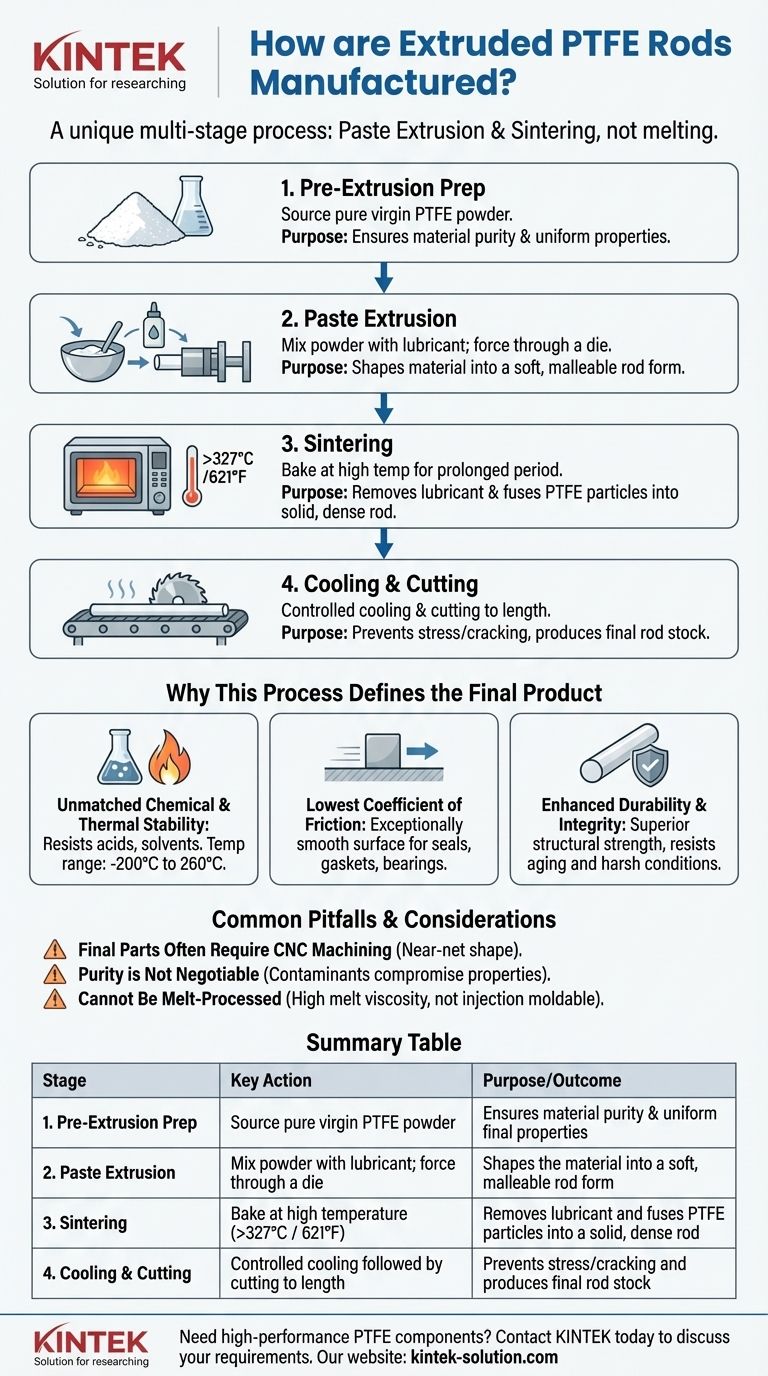

To manufacture extruded PTFE rods, a multi-stage process is used that involves mixing pure PTFE powder with a lubricant, extruding this paste-like mixture through a die under high pressure, and then baking the resulting shape in a high-temperature oven. This baking process, known as sintering, removes the lubricant and fuses the PTFE particles into a solid, durable rod. The process is distinct from typical plastic extrusion because PTFE does not truly melt and flow.

The core principle to grasp is that extruded PTFE rods are not made by melting plastic. Instead, a unique "paste extrusion" and sintering process is required to shape the material, which is precisely what imparts the final product with its renowned chemical resistance, thermal stability, and exceptionally low friction.

From Raw Material to Polymer Powder

Before a rod can be extruded, the raw Polytetrafluoroethylene (PTFE) material must be created. This is a foundational step in chemical engineering that sets the stage for the physical manufacturing process.

The Polymerization Stage

The journey begins with the creation of Tetrafluoroethylene (TFE) monomer gas. This gas then undergoes a chemical reaction called polymerization, where individual monomer molecules link together into long chains. This process converts the gas into the stable, solid, and fine white powder that serves as the raw material for extrusion.

The Four-Stage Rod Extrusion Process

Once the pure, virgin PTFE powder is ready, it goes through a carefully controlled four-stage process to become a finished rod.

Stage 1: Pre-Extrusion Preparation

The process starts with sourcing high-quality, pure virgin PTFE powder. The consistency and purity of this initial powder are critical for ensuring the final rod has uniform density and the desired mechanical properties.

Stage 2: Mixing and Paste Extrusion

The fine powder is mixed with a liquid lubricant, often a type of naphtha. This transforms the dry powder into a thick, paste-like substance called a preform.

This preform is then forced under immense pressure through a cylindrical die. This step shapes the material into its rod form but leaves it in a soft, malleable state.

Stage 3: Sintering - The Critical Transformation

The shaped rod is moved into a specialized oven for sintering. It is baked at a very high temperature (above 327°C or 621°F) for a prolonged period.

This critical step accomplishes two things: it burns off the lubricant used in the extrusion phase and causes the individual PTFE particles to fuse together. This fusion locks the polymer chains in place, creating a solid, dense, and structurally robust material.

Stage 4: Controlled Cooling and Cutting

After sintering, the rods are cooled in a highly controlled manner to prevent internal stresses or cracking. Once cooled and stabilized, they are cut to standard or custom lengths, ready for use or further machining.

Why This Process Defines the Final Product

The unique manufacturing method is directly responsible for the exceptional characteristics that make extruded PTFE so valuable in demanding industrial applications.

Unmatched Chemical and Thermal Stability

The sintering process creates a dense, non-porous structure with incredibly strong molecular bonds. This is what gives PTFE its ability to withstand a vast range of chemicals, including strong acids and solvents, and operate in extreme temperatures from -200°C to 260°C.

The Lowest Coefficient of Friction

The combination of high-pressure extrusion and particle fusion during sintering results in an exceptionally smooth and uniform surface. This molecular-level smoothness is why PTFE has one of the lowest coefficients of friction of any solid material, making it ideal for seals, gaskets, and slide bearings.

Enhanced Durability and Integrity

Compared to other forms of PTFE, the extrusion and sintering process imparts enhanced structural strength and durability. This ensures the material maintains its integrity and resists aging or degradation even when exposed to harsh conditions, ozone, or sunlight.

Common Pitfalls and Considerations

While powerful, the material and its manufacturing process have inherent realities that must be understood to be used effectively.

Final Parts Often Require Machining

The extrusion process produces a "near-net shape." For components requiring tight tolerances, the extruded rod must undergo secondary CNC machining. This allows for the precise creation of complex geometries with high repeatability.

Purity is Not Negotiable

The entire process relies on starting with pure, virgin PTFE. Any contaminants introduced into the powder can create weak points in the final sintered rod, compromising its mechanical or chemical properties.

It Cannot Be Melt-Processed

It is crucial to remember that PTFE has an extremely high melt viscosity, meaning it doesn't flow like a liquid when heated. This is why the complex paste extrusion and sintering process is necessary and why it cannot be injection molded like common plastics.

Making the Right Choice for Your Goal

Understanding the manufacturing process allows you to specify and use extruded PTFE rods effectively.

- If your primary focus is high-precision components: Plan for secondary CNC machining, as the extruded rod is the ideal starting stock, not the finished part.

- If your primary focus is extreme chemical or thermal environments: Trust that the sintering phase of manufacturing is what guarantees the rod's robust and inert characteristics.

- If your primary focus is low-friction performance: Recognize that the unique paste extrusion method is directly responsible for creating the material's signature smooth, low-drag surface.

By appreciating this unique manufacturing journey, you can confidently leverage the full potential of extruded PTFE in your most demanding applications.

Summary Table:

| Manufacturing Stage | Key Action | Purpose/Outcome |

|---|---|---|

| 1. Pre-Extrusion Prep | Source pure virgin PTFE powder | Ensures material purity and uniform final properties |

| 2. Paste Extrusion | Mix powder with lubricant; force through a die | Shapes the material into a soft, malleable rod form |

| 3. Sintering | Bake at high temperature (>327°C / 621°F) | Removes lubricant and fuses PTFE particles into a solid, dense rod |

| 4. Cooling & Cutting | Controlled cooling followed by cutting to length | Prevents stress/cracking and produces final rod stock |

Need high-performance PTFE components for your critical applications?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in paste extrusion and sintering ensures your parts deliver unmatched chemical resistance, thermal stability, and low friction. We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and material integrity every step of the way.

Contact KINTEL today to discuss your PTFE requirements and leverage our expertise for your most demanding projects.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech